Product Introduction

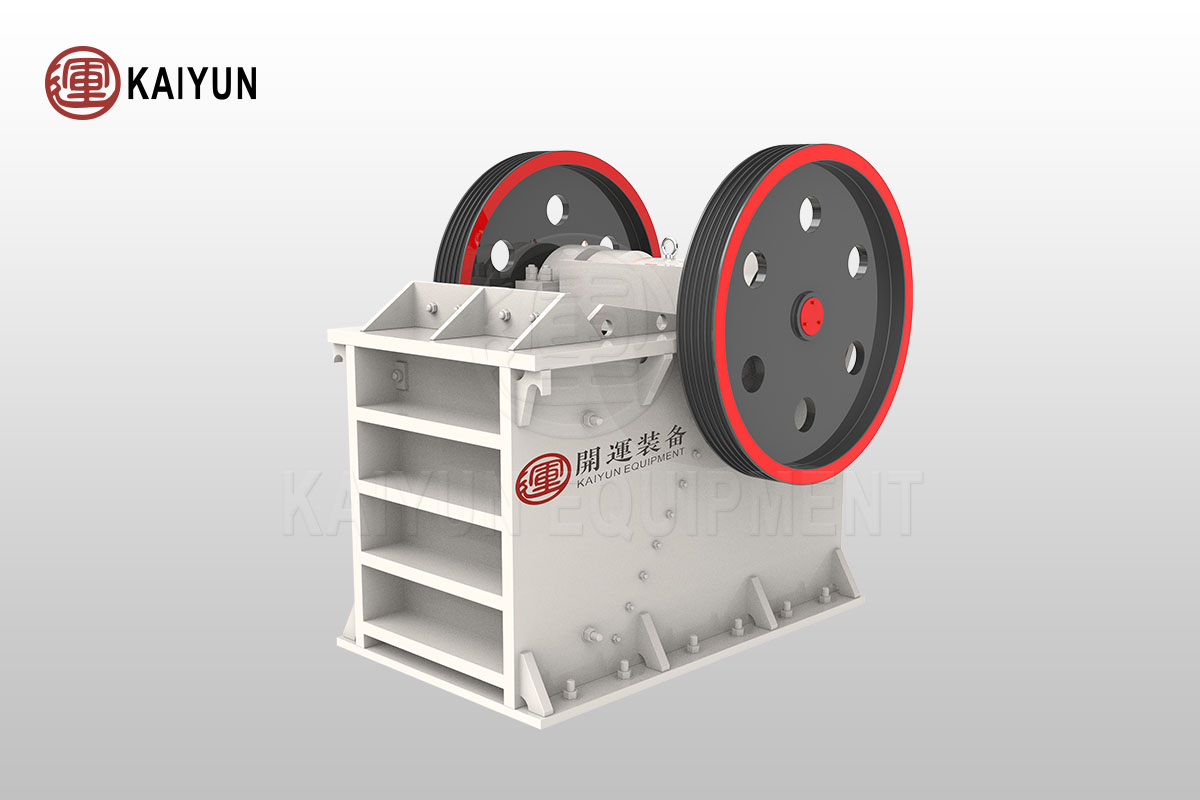

PE series jaw crusher is a high-capacity, high-crushing ratio, and high-efficiency crushing equipment developed by our company to meet customer market needs.

PE series jaw crusher is primarily used for coarse crushing and is particularly suitable for both stationary crushing production lines and mobile crushing stations.

PE series jaw crusher application industries: Quarries, Mines, Construction Materials, Metallurgy, Water Conservancy, Railways, etc.

PE series jaw crusher applicable materials: Limestone, River Pebbles, Iron Ore, Granite, Coal, Construction Waste, etc.

Table of Contents

Working Principle

PE series jaw crusher operates with the electric motor driving the belt and the belt wheel. This drives the movable jaw in a periodic motion around the fixed jaw, causing the material located between the two jaws to be crushed through compression.

PE series jaw crusher consists primarily of a frame, eccentric shaft, large pulley, flywheel, movable jaw, fixed jaw plate, movable jaw plate, side guard plate, elbow plate, gap adjusting screw, and reset spring. The elbow plate also serves as a safety device.

Product Advantages

⚙️Powerful power

High-strength alloy bearings provide strong crushing force and stable operation.

🔄Adjustable discharge

Adjustable discharge port accommodates a variety of particle sizes.

🧱Applicable to a wide range of materials

Crushes granite, limestone, ore, construction waste, and more.

🔩Long-lasting wear-resistant parts

High-manganese steel jaws extend service life by over 30%.

🧰Simple structure and easy maintenance.

Compact stand-alone unit allows for quick maintenance and reduces labor costs.

🚛Mobile configuration

Optional crawler or tire mobile station adapts to complex construction sites.

Technical Parameters

| Model | Max.Feed Size (mm) | Adjusting Range(mm) | Spindle Speed (r/min) | Capacity (t/h) | Motor Power (kw) | Dimension(mm) |

| PE500×750 | 425 | 50-100 | 275 | 40-100 | 55 | 2050×1920×2000 |

| PE600×900 | 480 | 65-160 | 250 | 90-180 | 75 | 2290×2206×2370 |

| PE750×1060 | 630 | 80-140 | 250 | 110-320 | 110 | 2655×2302×3110 |

| PE900×1200 | 750 | 95-165 | 225 | 220-450 | 132 | 3800×3170×3045 |

| PE1000×1200 | 850 | 195-265 | 200 | 310-560 | 132 | 5350×4280×3050 |

| PE1200×1500 | 1020 | 150-300 | 180 | 400-800 | 200 | 6380×5300×3710 |

| PEX250×1000 | 210 | 20-60 | 330 | 15-50 | 30 | 1530×1992×1380 |

| PEX250×1200 | 210 | 20-60 | 330 | 20-60 | 37 | 3045×1525×1430 |

| PEX300×1300 | 250 | 20-90 | 300 | 30-90 | 55-75 | 1920×2235×1635 |