Product Introduction

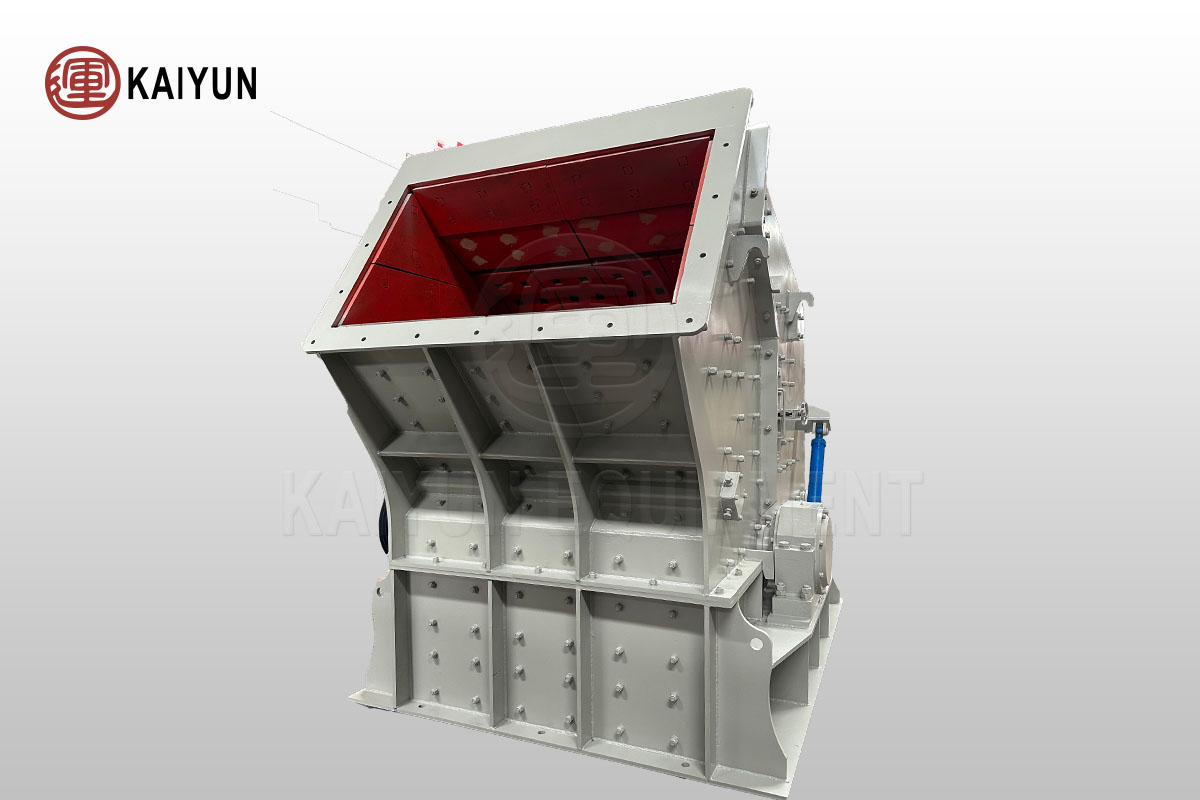

Kaiyun PF series impact crusher, as a high-performance crushing equipment designed for aggregate and mining industries, has become an ideal choice for coarse, medium and fine crushing operations, as well as recycling applications with its excellent crushing performance and wide applicability.

Kaiyun PF series impact crusher is heavy-duty rotor design and unique crushing chamber structure ensure the stability of equipment operation. At the same time, the particle quality of the final product has been significantly improved, meeting the industry’s demand for high-precision crushing results.

Kaiyun PF series impact crusher has become an indispensable key equipment for modern industry that pursues efficient, economical and environmentally friendly crushing solutions due to its excellent crushing performance, modular design, use of high-wear-resistant materials, intelligent hydraulic system and personalized configuration options.

Table of Contents

Product Features

⚙️ Cost-effective design

Simple structure and low cost, widely used in small and medium-sized crushing lines.

📐 Fine-quality output with low flake content

Adjustable impact angle for optimized particle shape, suitable for concrete aggregates.

🔧 Easy replacement of wearing parts

Simple replacement of blow bars and liners, low maintenance costs.

🧱 Suitable for a variety of medium-hard materials

Stable crushing results for limestone, concrete, bricks, coal gangue, etc.

🏗️ Supports fixed or mobile crushing configurations

PF series impact crusher can be integrated into tire or crawler mobile crusher systems.

🔄 Optional manual or hydraulic cover opening

PF series impact crusher, Enhanced access efficiency and convenient daily maintenance.

Working Principle

Kaiyun PF series impact crusher adopts the principle of impact energy crushing. The motor drives the rotor to rotate at high speed. When the material enters the plate hammer action area, it is first crushed by the strong impact of the plate hammer on the rotor, and then thrown onto the impact device for secondary crushing.

After the material rebounds from the impact liner, it collides with the plate hammer again. This process is repeated. The material passes through the first, second, and third impact chambers from large to small until it reaches the required particle size and is finally discharged from the discharge port.

By adjusting the gap between the impact frame and the rotor, users can easily control the discharge particle size and shape of the material to meet specific production needs.

Applications

Application Industries

Construction aggregate plants

Highway/railway projects

Urban demolition and construction waste disposal

Small and medium-sized quarries

Typical Materials

Limestone, concrete, shale, coal gangue, bricks, construction waste, quartz stone, medium-hard stone, etc.

Technical Parameters

| Model | Inlet Size(mm) | Rotor Size(mm) | Max. Feed(mm) | Copacity (t/h) | Motor Power(kw) | Dimension(LxWxH)(mm) |

| PF-1010 | 400×1080 | φ1000×1050 | 300 | 50-90 | 75 | 2440x2250x2630 |

| PF-1210 | 400×1080 | φ1250×1050 | 350 | 70-130 | 110 | 2700x2340x2900 |

| PF-1214 | 400×1430 | φ1250×1400 | 350 | 90-180 | 132 | 2700x2690x2890 |

| PF-1315 | 860×1520 | φ1320×1500 | 350 | 120-260 | 200 | 3100x3280x2670 |

| PF-1320 | 860×2030 | φ1320×2000 | 500 | 160-350 | 250 | 3329x3205x3279 |

| PF-1520 | 2040×1315 | φ1512×2000 | 700 | 280-450 | 2*250 | 3849x3422x3649 |

| PF-1620 | 2040×1315 | φ1612×2000 | 700 | 350-550 | 2*250 | 3949x2520x3426 |

| PF-1820 | 1620×2040 | φ1800×2000 | 700 | 450-800 | 2*315 | 4471x3250x4008 |