Product Introduction

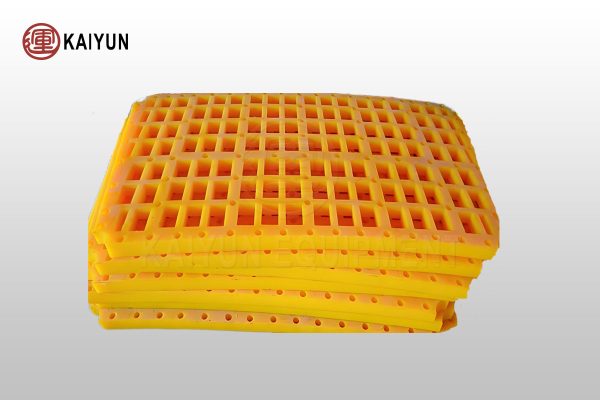

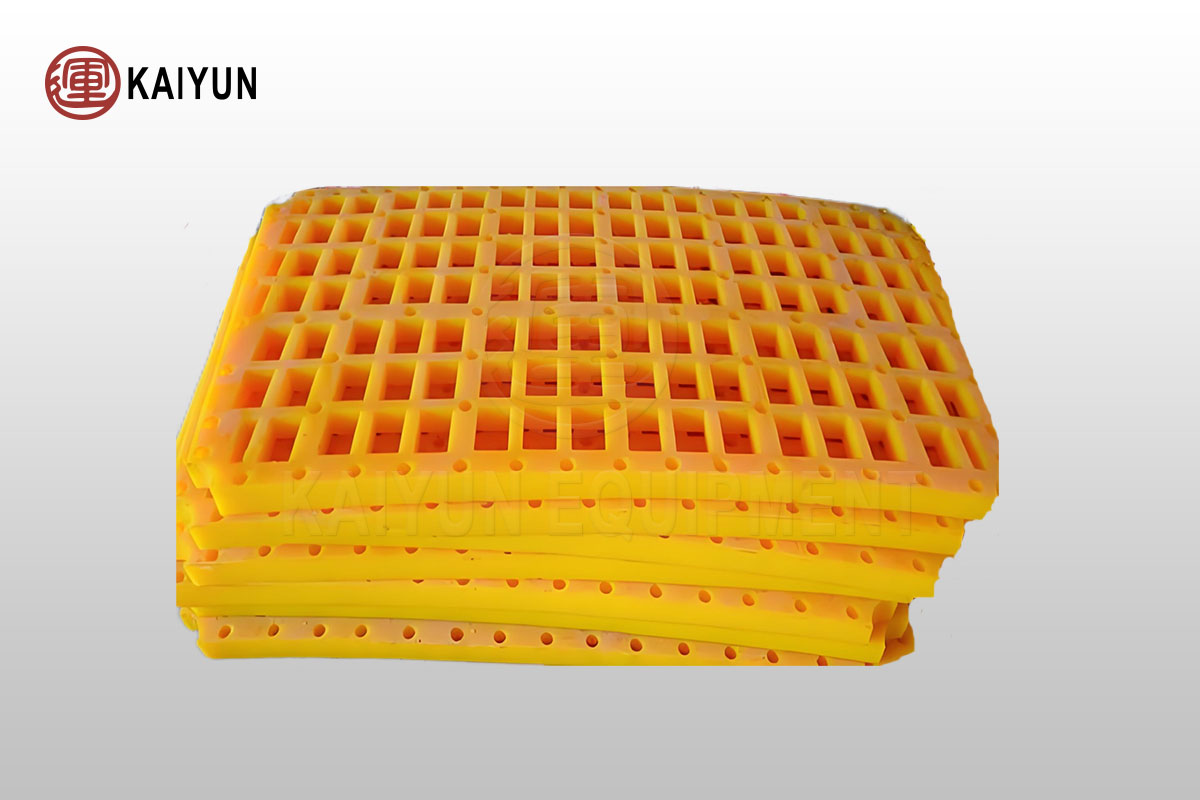

Polyurethane screen mesh represent a significant advancement in screening technology as a crucial component of screening machinery. The evolution from early metal and rubber materials to the widely used polyurethane material reflects not only progress in material science but also a continuous pursuit of improved screening efficiency, load-bearing capacity, and service life.

With its unique properties and advantages, polyurethane screen mesh has become a standout product in the screening industry.

Table of Contents

Core Advantages and Features

High Open Area and Load-Bearing Capacity

Polyurethane screen mesh boasts a high open area, which translates to a larger screening surface and higher screening efficiency. Additionally, its excellent load-bearing capacity ensures stable performance under heavy loads.

Long Service Life

The wear resistance and corrosion resistance of polyurethane materials significantly extend the service life of the screen mesh, reducing the frequency of replacements and lowering maintenance costs.

Wide Adaptability

Polyurethane screen mesh is suitable for screening a variety of materials, whether they are hard, impact-resistant ores like iron ore, limestone, fluorite, and furnace slag, or materials from industries such as coal, chemicals, construction, hydropower, abrasive waste processing, and quarries, demonstrating outstanding screening performance.

Wear-Resistant Screening Plates

Designed for extreme conditions, polyurethane screen mesh features specially engineered wear-resistant screening plates. It effectively handles fine crushing and screening in iron ore processing, raw coal classification, gold extraction, and screening of sand and gravel for construction and hydropower, ensuring high efficiency and durability in the screening process.

Application Fields

Polyurethane screen mesh, known for its versatility and superior performance, is widely used in various industries including metallurgy, non-ferrous metals, coal, chemical engineering, building materials, hydropower projects, abrasive waste processing, and quarries. It is an indispensable tool for material classification, dewatering, and desliming in screening operations.