Introduction

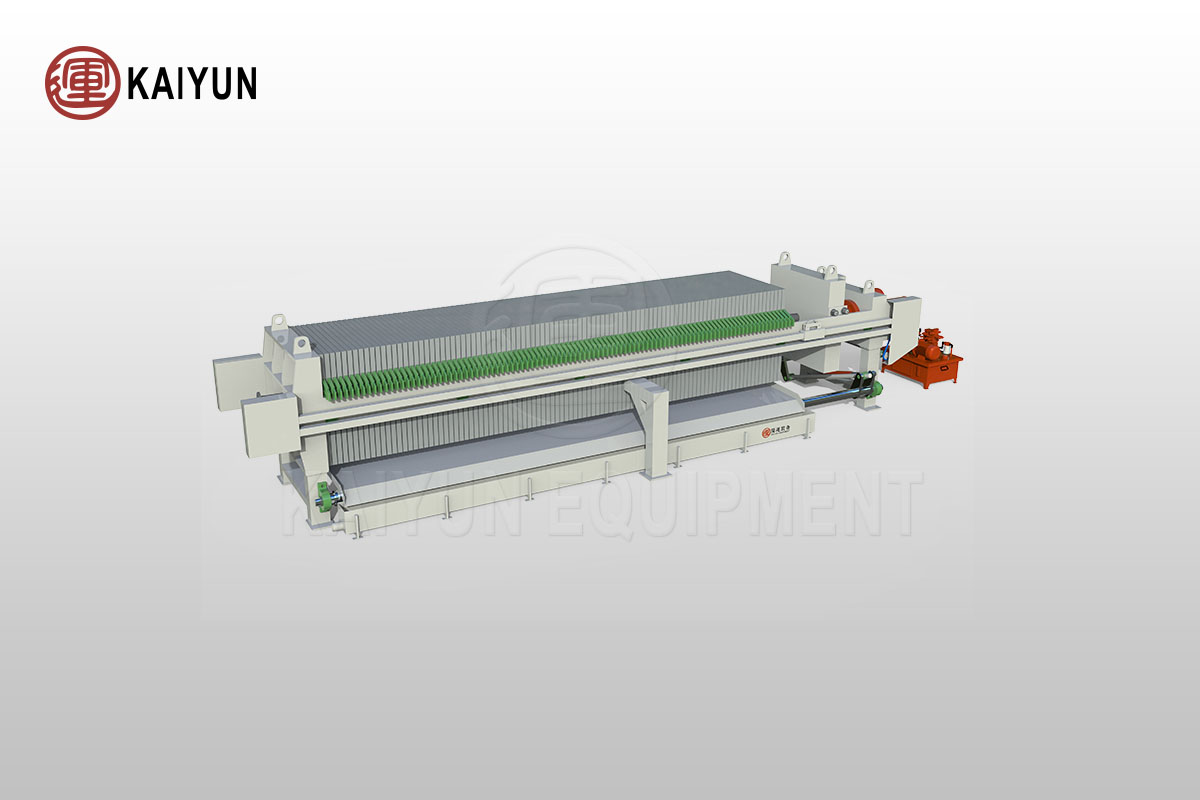

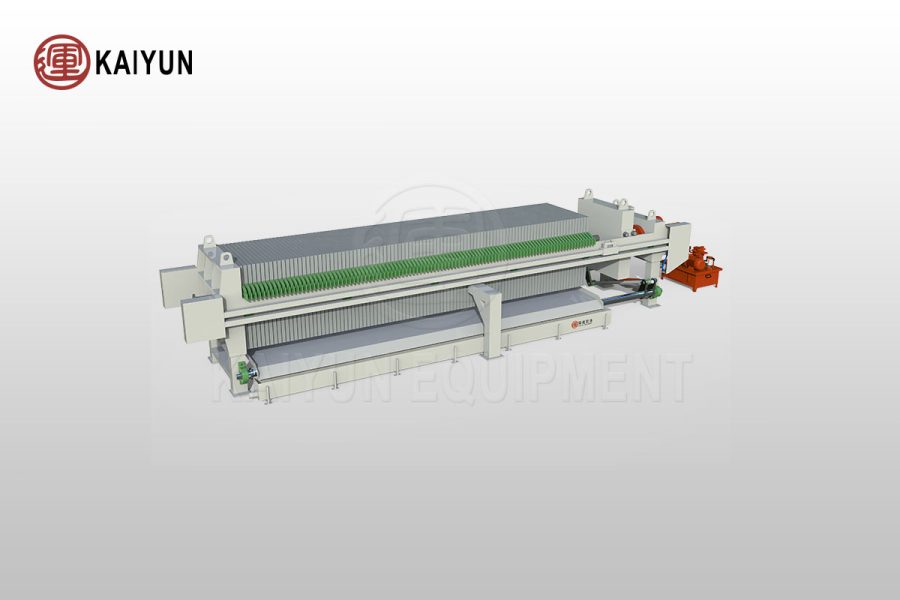

Press filter is a common solid-liquid separation equipment, widely used in chemical, pharmaceutical, food processing, environmental protection, mining, metallurgy and other industries. Its main working principle is to use the alternating arrangement of filter plates and filter frames, and apply pressure through external force to make the liquid in the slurry discharge through the filter cloth, while the solid particles are trapped in the filter chamber, thereby achieving solid-liquid separation.

Main application areas

Chemical industry: sewage treatment and material separation in dyes, pigments, petrochemicals and other industries.

Food industry: solid-liquid separation in the production process of juice, starch, vegetable oil, winemaking, etc.

Pharmaceutical industry: extraction of traditional Chinese medicine, filtration of antibiotic fermentation broth.

Environmental protection industry: sewage treatment, sludge dehydration, waste liquid recovery, etc.

Working principle

1. Feeding: The slurry to be filtered is fed into the filter press through the feed pump and enters the filter chamber.

2. Pressurized filtration: The liquid passes through the filter cloth under pressure and flows into the drainage channel for discharge. The solid particles are trapped on the filter cloth to form a filter cake.

3. Filter cake formation: As the filtration proceeds, the filter cake thickness gradually increases, and the filtration resistance increases until the set filtration time or pressure is reached.

4. Discharging: Open the filter plate, remove the filter cake, and complete a filtration cycle.

Product features

Good filtration effect

Press filter can effectively separate solids and liquids, the filtrate is clear, and the solid water content is low.

Easy to operate

Press filter,compact structure, high degree of automation, can realize functions such as automatic plate pulling and automatic cake unloading.

Strong corrosion resistance

corrosion-resistant materials such as stainless steel and polypropylene can be selected, suitable for acid and alkali environment.

Wide applicability

Press filter can be used for filtering various suspensions, adapting to materials of different concentrations and viscosities.

Easy maintenance

Press filter easy replacement of parts, low operating cost and long service life.

Parameter

| Model | Filtration Area (㎡) | Filter Chamber Quantity | Filter Plate Size (mm) | Filter Cake Thickness (mm) | Filter Chamber Volume (m³) | Filtration Pressure (MPa) | Overall Dimensions (mm) | Motor Power (kw) | Weight (kg) |

| KM/AZ 20/800U | 20 | 20 | 800×800×60 | 30 | 0.287 | 0.5~1.6 | 3500×1350×1160 | 2.2 | 2750 |

| KM/AZ 50/1000U | 50 | 32 | 1000×1000×60 | 30 | 0.75 | 0.5~1.6 | 4720×1480×1280 | 2.2 | 4800 |

| KM/AZ 100/1250U | 100 | 62 | 1250×1250×65 | 32 | 1.48 | 0.5~1.6 | 6910×1560×1360 | 2.2 | 8680 |

| KM/AZ 200/1500U | 200 | 77 | 1500×1500×70 | 32 | 3.22 | 0.5~1.6 | 8550×1770×1620 | 4 | 13300 |

| KM/AZ 400/2000U | 400 | 114 | 2000×2000×83 | 40 | 15.97 | 0.5~1.6 | 14460×2900×2450 | 11 | 65200 |