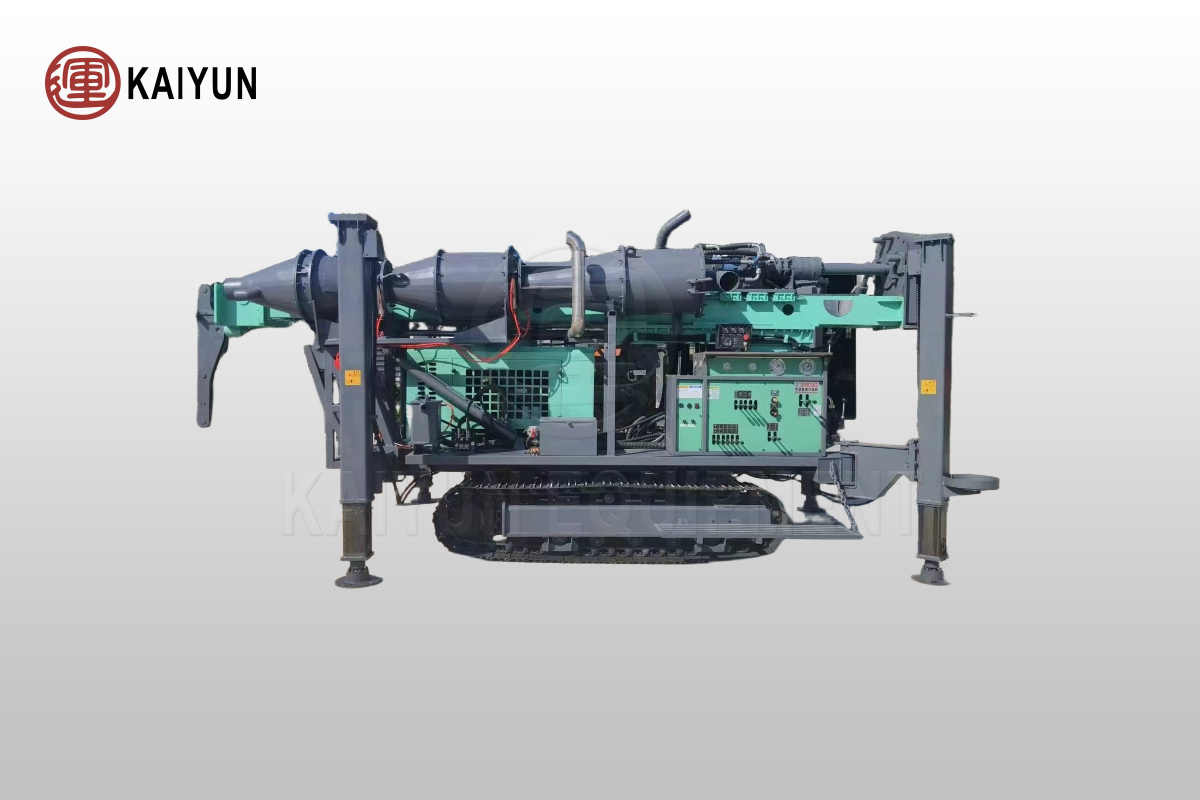

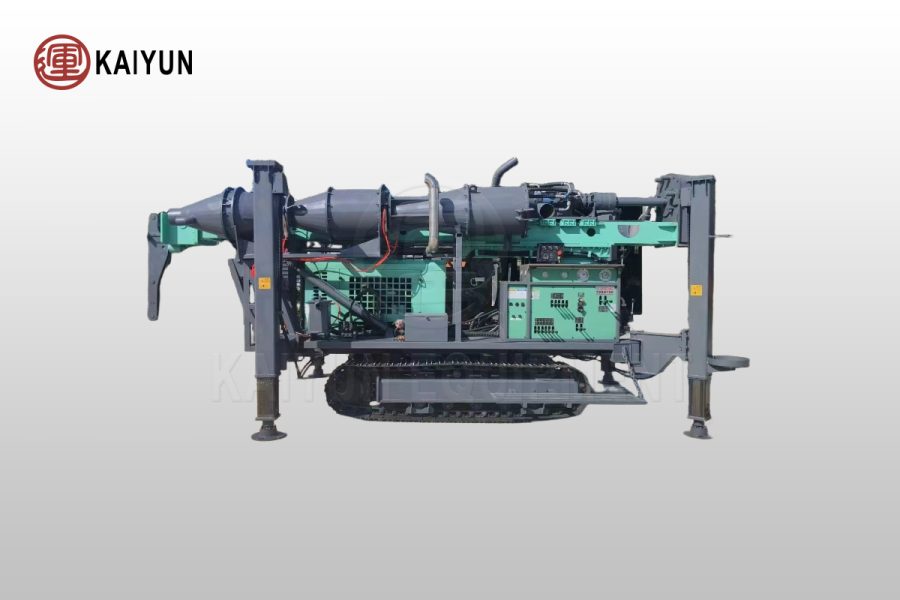

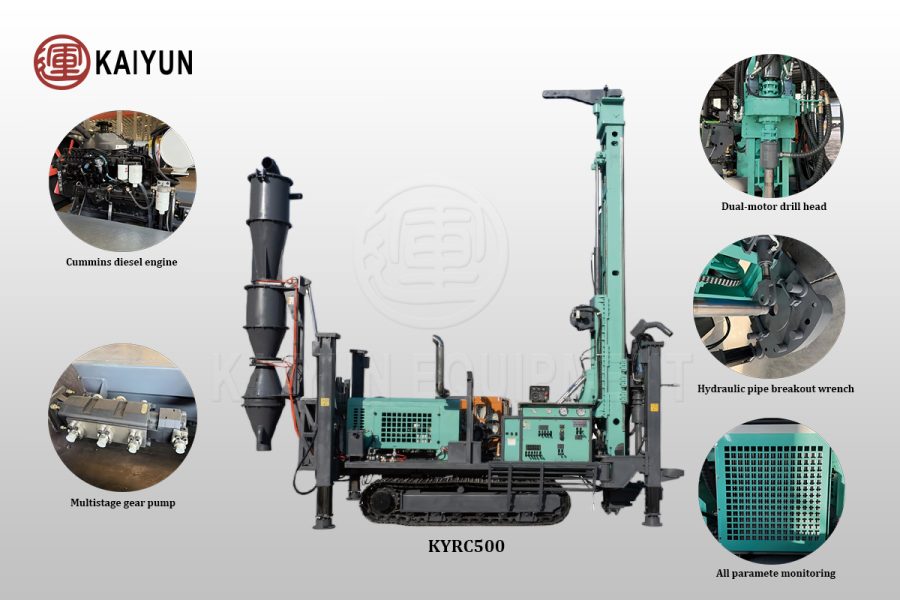

Product Introduction

Reverse circulation drilling rig is a new, efficient, environmentally friendly, multifunctional crawler drilling rig. It uses double-wall drill pipe. After the inner tube is discharged, the slag is collected by a cyclone collector. It can be used for sampling and analysis in geological exploration departments. Compressed air reverse circulation down-the-hole drilling can be used in various strata. The drilling rig drilling frame lifting, drilling frame compensation, drill pipe loading and unloading, rotation and feeding, outriggers, winches, walking and other actions are all realized by the hydraulic system, which greatly reduces the labor intensity and improves the construction efficiency and engineering quality.

Reverse circulation drilling rig is a high-efficiency drilling equipment commonly used in mineral exploration, geological sampling, water well drilling and other fields. It is especially suitable for fast and low-pollution sampling drilling in complex strata such as hard rock and weathered rock.

Working Principle

The reverse circulation drilling rig adopts a double-layer drill pipe structure, and drills by sending air through the outer pipe and returning samples through the inner pipe;

High-pressure air is sent to the bottom of the hole from between the drill pipe and the hole wall;

Drill cuttings and rock powder are carried into the inner pipe under the action of air pressure difference;

Then enter the sample collection system through the cyclone separator.

This method is called reverse circulation, which is opposite to conventional positive circulation drilling.

Main Features

1. Efficient sampling

The sample is returned from the inner tube of the drill pipe, with fast speed and less pollution; suitable for mineral sample analysis.

2. Save time

No need to repeatedly replace the drill bit or clean the hole, suitable for large-scale prospecting projects.

3. Widely applicable strata

Can be used for complex strata such as sand layers, weathered layers, and hard rock layers.

4. High sample purity

Gas transmission does not contact the hole wall, effectively preventing cross contamination.

5. Deep hole drilling

Can achieve a drilling depth of more than hundreds of meters.

Parameter

| Rig type | KYRC350 | KYRC500 |

| Weight | 8000kg | 12000kg |

| Dimension (transport) | 5900*2100*2500mm | 6300*2100*2500mm |

| Dimension (working) | 4200*3000*6100mm | 4500*3000*6800mm |

| Drilling depth | 350m | 500m |

| The hole diameter | 105-400 | 105-400 |

| Drill pipe diameter | 76/89/102 | 76/89/102/114 |

| Drill head lift force | 260kN | 300kN |

| Drill head feed force | 130kN | 150kN |

| Rotary speed RPM | 40-160rpm | 40-160rpm |

| Max. Torque | 10000N.m | 12000N.m |

| Drill head feed stroke | 3300mm | 3300mm |

| Drill mast slide stroke | 800mm | 1 000-m |

| Hydraulic pumps | 100ml/r.16MPa | 160ml/r.16MPa |

| Hydraulic cooling system | Air cooling | Air cooling |

| Mechanical winch capacity | 15kN | 20kN |

| Power unit | Weichai 6-cylinder engine | Cummins 6-cylinder engine |

| Air pressure | 1.7-3.5MPa | 1.7-3.5MPa |

| Air consumption | 17-42m³*/min | 17-42m³*/min |

| Equipped with hammer | Medium and high pressure series | |

| Mud pump | BT160/BW250(optiona1) | |

| Crawler | 8t Steel 400 mm | 12t Steel 400 mm |

| Crawler climbing angle | 25° | 25° |

| Crawler walking speed | 2-3km/h | 2-3km/h |

Note: The above parameters are subject to change without further notice. Please refer to the actual product.