Product Introduction

The screw conveyor is a highly efficient mechanical device that utilizes a driving mechanism to rotate a screw, thus pushing and transporting materials continuously. It is widely used for the conveyance of powdery, granular, and small-sized materials such as ore powder, coal powder, soda ash, recycled rubber powder, zinc oxide, calcium carbonate, and small lumps of coal.

However, it is not suitable for transporting materials that are prone to deterioration, high in viscosity, or prone to caking, which limits its application range in specific material handling fields.

Advantages and Features

Simple Structure, Compact Design

The screw conveyor’s straightforward design and small cross-sectional dimensions save space, facilitate installation and maintenance, and are especially suitable for industrial environments with limited space.

Excellent Sealing, Reliable Performance

The equipment’s sealing design ensures material safety and hygiene during the conveying process, reduces material loss, and enhances overall operational reliability.

Bidirectional Conveying, Flexible Application

The conveyor can operate in both forward and reverse directions, allowing for single-direction or simultaneous bidirectional conveying, significantly improving the device’s flexibility and adaptability.

Multifunctional Operation, Efficiency Enhancement

The screw conveyor can perform additional tasks such as stirring, mixing, heating, and cooling of materials during the conveying process, enabling multifunctionality and increasing production efficiency.

Flow Control, Precise Regulation

The flow rate of materials can be accurately controlled through the adjustment of inlet and outlet gates, meeting various production needs and ensuring stable and even material supply.

Customizable Service, Personalized Solutions

The conveyor can be customized according to specific operational conditions and customer requirements, ensuring perfect alignment with application scenarios and enhancing the effectiveness and relevance of the overall solution.

Working Principle

The core working principle of the screw conveyor is based on the cooperation between its unique spiral structure and the driving mechanism. The driving mechanism rotates the spiral blades, causing the material to move forward along the spiral path within the trough.

The material does not rotate with the spiral blades due to its own weight and the frictional resistance between the material and the conveyor casing. This characteristic ensures stable material transport, avoids unnecessary wear between the material and the spiral blades, and extends the service life of the equipment.

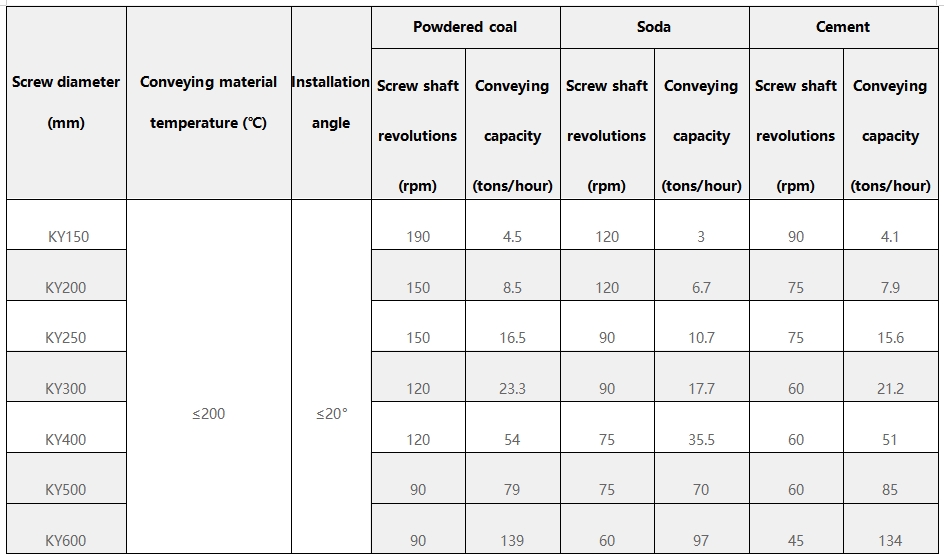

Technical parameters