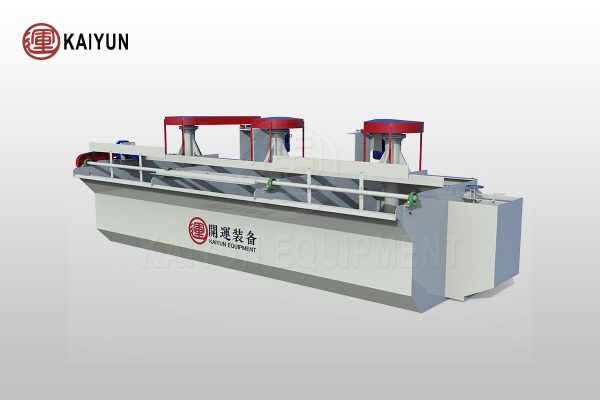

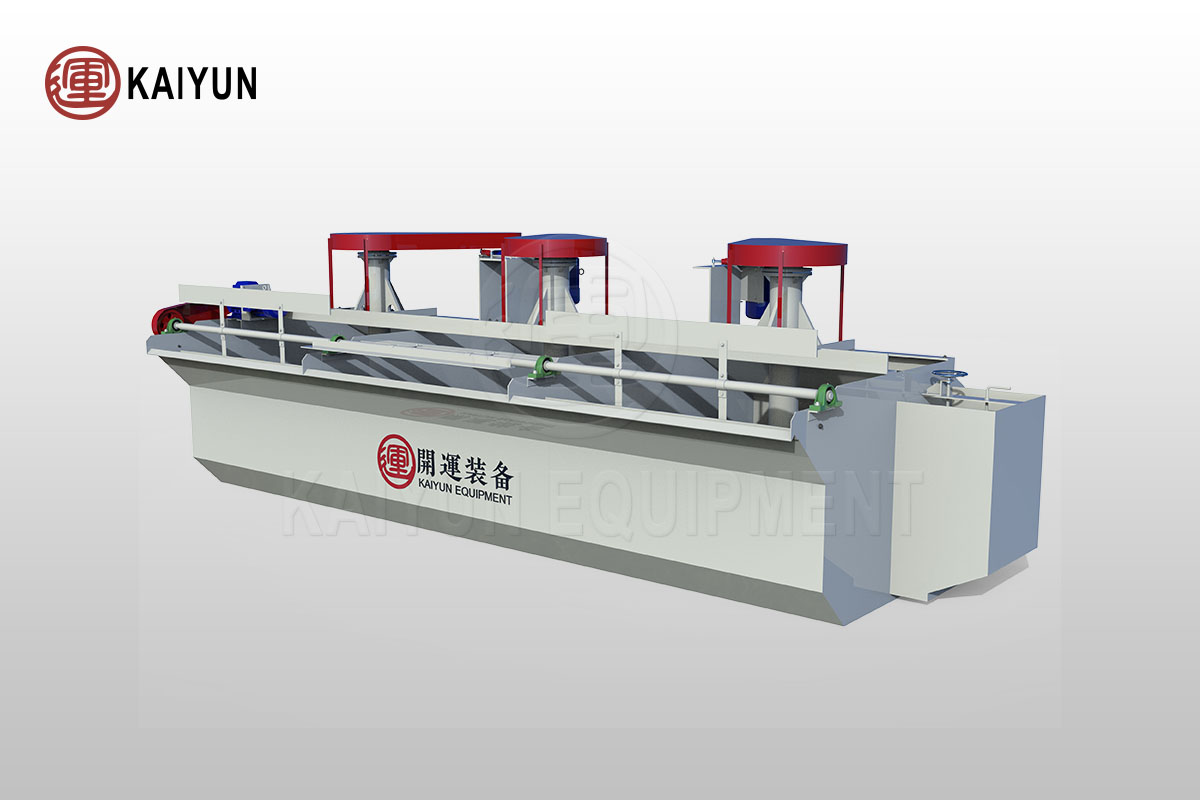

Product Introduction

The SF mechanical agitation flotation machine, as a high-efficiency flotation equipment that integrates self-priming slurry and self-priming air functions, is widely used for the selection of non-ferrous metals, ferrous metals, and non-metallic minerals.

The SF mechanical agitation flotation machine is particularly suitable for roughing and scavenging operations in large and medium-sized flotation plants, demonstrating its strong capabilities and flexibility in handling complex ores.

Table of Contents

Working Principle

The core structure of the SF mechanical agitation flotation machine includes a slurry tank, agitation device, air inflation device, discharge mineralized bubble device, and motor.

When the motor drives the impeller through a V-belt transmission, the rotation of the impeller generates centrifugal force, creating a negative pressure effect.

The slurry above the cover plate is drawn into the upper impeller cavity through the circulation holes in the cover plate, forming the upper circulation of the slurry.

Simultaneously, as the lower blades expel the slurry outward, the slurry below replenishes toward the center, constructing the lower circulation of the slurry.

Air is sucked into the upper impeller cavity through the air suction pipe and central tube, mixing with the slurry to form a large number of fine bubbles. These bubbles are evenly dispersed in the tank under the steady flow action of the cover plate, combining with the mineral particles in the slurry to form mineralized bubbles.

The mineralized bubbles rise to the foam layer due to buoyancy and are scraped out by a scraper, thus completing the preliminary separation and concentration of the minerals.

Advantages and Features

Dual Circulation Impeller Design

The impeller with backward-inclined double-sided blades achieves bidirectional circulation of the slurry in the tank, improving the mixing efficiency of the slurry and air and enhancing flotation performance.

High Air Suction and Low Energy Consumption

The large gap design between the impeller and cover plate ensures sufficient air intake while reducing energy consumption, thereby improving the economic efficiency of the equipment.

Low Speed Operation and Long Lifespan

The low peripheral speed of the impeller reduces wear on the consumable parts, extending the equipment’s lifespan and lowering maintenance costs.

Optimized Tank Structure

The forward-inclined tank design reduces dead zones, accelerates foam movement, improves flotation efficiency, and ensures the purity of the foam product.

Integrated Self-Priming Function

The SF flotation machine integrates self-priming air and slurry functions, simplifying the operation process and enhancing continuity and efficiency of the operation.

Technical Parameters

| Model | Effective Volume (m³) | Processing Capacity (m³/min) | Impeller diameter (mm) | Impeller speed (r/min) | Stirring motor power (kw) | Scraper motor power (kw) | Single Tank Weight (kg) |

| SF-0.37 | 0.37 | 0.2~0.4 | 300 | 352-442 | 1.5 | 0.55 | 468 |

| SF-0.7 | 0.7 | 0.3~1.0 | 350 | 336-384 | 3 | 1.1 | 629 |

| SF-1.2 | 1.2 | 0.6~1.6 | 450 | 312 | 5.5 | 1.1 | 1373 |

| SF-2 | 2 | 1.5 ~3 | 550 | 280 | 11 | 1.5 | 1879 |

| SF-2.8 | 2.8 | 1.5~3.5 | 550 | 280 | 11 | 1.5 | 1902 |

| SF-4 | 4 | 2.0 ~4 | 650 | 235 | 15 | 1.5 | 2582 |

| SF-6 | 6 | 3~6 | 760 | 191 | 30 | 2.2 | 3540 |

| SF-8 | 8 | 4.0 ~8 | 760 | 191 | 30 | 2.2 | 4129 |

| SF-16 | 16 | 5.0 ~16 | 850 | 169-193 | 45 | 1.5 | 7415 |

| SF-20 | 20 | 10 ~12 | 850 | 169-193 | 45 | 1.5 | 9828 |