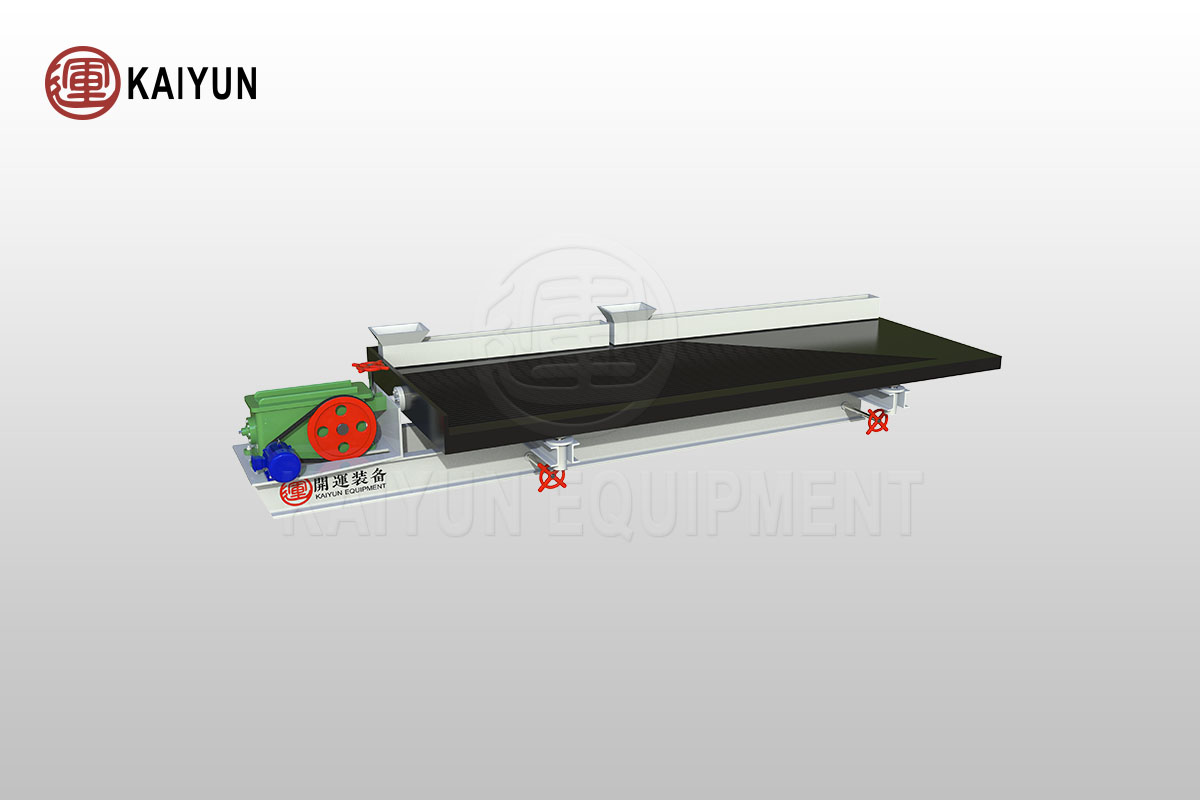

Product Introduction

The shaking table from Kaiyun Equipment, designed to achieve efficient mineral separation through asymmetric reciprocating motion on the table surface, has become an invaluable tool in roughing, concentrating, and scavenging operations.

The shaking table unique design and excellent performance make it suitable for processing iron, manganese ores, and materials of varying particle sizes, including coarse sand (2-0.5 mm), fine sand (0.5-0.074 mm), and mineral mud (-0.074 mm).

This versatility and flexibility highlight its broad applicability in various mineral processing tasks.

Table of Contents

Advantages and Features

Wide Adjustment Range

The shaking table offers a broad range of transverse slope adjustment (0° to 10°) and easily adjustable stroke, providing users with precise control over separation conditions.

Durable Bed Surface

The flat bed surface features excellent corrosion resistance, is robust and durable, resistant to deformation, and allows for localized repairs, extending the equipment’s lifespan.

Smooth Operation and Compact Structure

Even during adjustments to the transverse slope and stroke, the shaking table maintains smooth operation. The springs are housed within the machine case, ensuring a compact structure.

Low Maintenance and Eco-Efficiency

The bedhead mechanism operates reliably with fewer wear-prone parts and no oil leakage, reducing maintenance costs. Additionally, the shaking table is cost-effective, requires no reagents, and has very low power consumption, offering both environmental and economic benefits.

Working Principle

The ore particles are fed into the feed trough at the upper corner of the shaking table, and the water supply trough provides horizontal flushing water. Under this environment, the ore particles are layered according to their specific gravity and particle size under the combined effects of gravity, horizontal water flow, inertia generated by the reciprocating asymmetric motion of the bed surface, and friction, and move longitudinally and transversely along the bed surface.

Due to the differences in specific gravity and particle size, the ore particles gradually flow down in a fan shape along their respective movement paths, and are finally discharged from different areas on the concentrate end and tailings side of the shaking table, and are accurately divided into concentrate, middlings, and tailings, realizing efficient utilization and refined processing of mineral resources.

Technical Parameters

| Model | Coarse sand bed surface | Fine sand bed surface | Gravure bed surface |

| Bed size (mm) | 4436*1825*1536 | ||

| Stroke (mm) | 16~22 | 10~16 | 10~16 |

| Stroke frequency (r/min) | 240~290 | 300~320 | 330~340 |

| Water consumption (t/h) | 190 | 80 | 50 |

| Capacity (t/h) | 30 | 8 | 8 |

| Feed size (mm) | 2~0.2 | 0.5 ~0.037 | 0.074~0.019 |

| Feed concentration (%) | 20~25 | 15~20 | 15~20 |

| Installation slope (°) | 2°30″ | 1°50″ | 0°45” |

| Overall dimensions (mm) | 5454*1825*1242 | ||

| Adjustable stroke range (mm) | 8~22 | ||

| Power (kw) | 1.5 | ||

| Weight (kg) | 1012 | ||