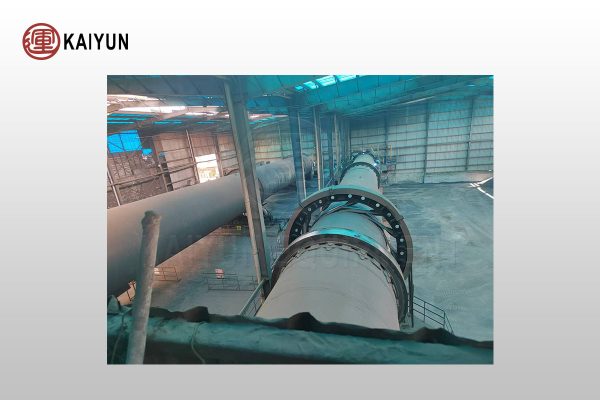

Product Introduction

The environmentally friendly solid and hazardous waste disposal rotary kiln is a high-temperature incineration equipment specially used for the treatment of solid waste and hazardous waste (referred to as “solid and hazardous waste”).

Solid and hazardous waste disposal rotary kiln is a key device for the harmless, reduced and resource-based treatment of various hazardous wastes such as industrial waste, medical waste, and chemical waste. Under the background of increasingly stringent environmental protection requirements, solid and hazardous waste disposal rotary kilns are widely used in the safe disposal of various types of hazardous wastes to ensure that environmental pollution is minimized.

Table of Contents

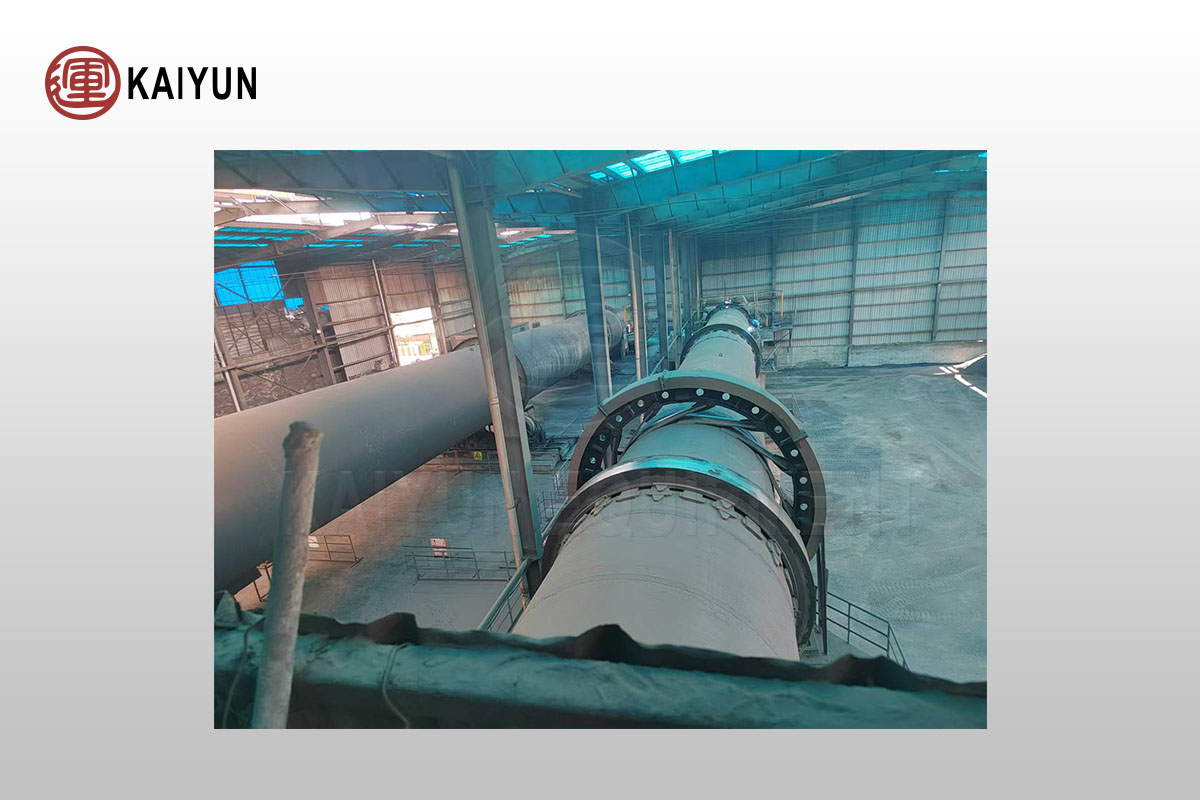

Structural Composition

1. Rotating cylinder: mainly used for the incineration and decomposition of waste, the inner wall of the cylinder is lined with refractory materials to withstand high temperature environments.

2. Transmission system: The rotation of the rotary kiln is driven by an electric motor and a reducer to ensure uniform combustion of waste.

3. Combustion device: Provides the high temperature required for incineration, usually using natural gas, heavy oil, coal or waste fuel as fuel.

4. Secondary combustion chamber: used to further treat harmful gases that are not completely burned in the first incineration to ensure the thorough decomposition of toxic substances.

5. Tail gas treatment system: including dust collector, desulfurization device, denitrification device and tail gas cooling system to ensure that gas emissions meet environmental protection requirements.

6. Discharging device: used to discharge the residue after incineration, and cool and further process it.

Working principle

The solid and hazardous waste rotary kiln converts hazardous waste into harmless substances through high-temperature incineration, and controls the emission of harmful gases through the tail gas treatment system. Its working principle is as follows:

1. Feeding: solid and hazardous waste is fed into the rotary kiln through the feeding device. The waste can be solid, liquid or gas.

2. Incineration and decomposition: The high temperature environment in the rotary kiln (usually 850℃-1200℃) allows the waste to be thermally decomposed and burned under sufficient oxygen conditions to decompose harmful substances.

3. Secondary combustion: For the toxic gases generated during high-temperature incineration, the rotary kiln system is generally equipped with a secondary combustion chamber to further burn them and ensure that the toxic gases are completely decomposed.

4. Cooling and slag discharge: The slag produced by incineration is discharged through the discharging device and cooled to form stable harmless substances.

5. Tail gas treatment: The exhaust gas generated during the incineration process is discharged after meeting the environmental protection emission standards through dust removal, desulfurization, denitrification and other treatment devices.

Advantages

1. Efficient incineration: The rotary kiln can fully incinerate various types of waste at high temperatures, especially for difficult-to-treat hazardous wastes, and can also achieve complete decomposition.

2. Strong processing capacity: The rotary kiln can continuously process large-scale solid, liquid and gaseous wastes, and has strong adaptability.

3. Strong environmental protection: Equipped with a complete tail gas treatment system, it can effectively reduce the emission of harmful gases and dust, and meet strict environmental protection regulations.

4. Waste reduction: After the rotary kiln incineration treatment, the volume and weight of the waste are greatly reduced, which is conducive to subsequent landfill or further resource treatment.

5. Harmless treatment: Through high-temperature incineration, the toxic and harmful components in the hazardous waste are completely decomposed or converted into harmless substances.

Application areas

Industrial waste disposal

Treatment of solid and liquid hazardous wastes generated by petrochemical, chemical, pharmaceutical, metallurgical and other industries.

Medical waste disposal

Used for incineration and treatment of medical waste generated by hospitals and medical institutions, including pathological waste, infectious waste, drug waste, etc.

Oily waste treatment

Treat oily sludge, waste oil barrels and other wastes generated by the oil industry to prevent secondary pollution.

Electronic waste treatment

Rotary kilns can also be used to treat electronic waste containing heavy metals and toxic and hazardous substances, such as used batteries, discarded circuit boards, etc.

Sewage treatment plant sludge treatment

Used to dispose of sludge containing heavy metals or other harmful components generated by sewage treatment plants.

Resource utilization

The incineration residue after rotary kiln treatment can be used as a raw material for building materials, reducing dependence on natural resources.