Product Introduction

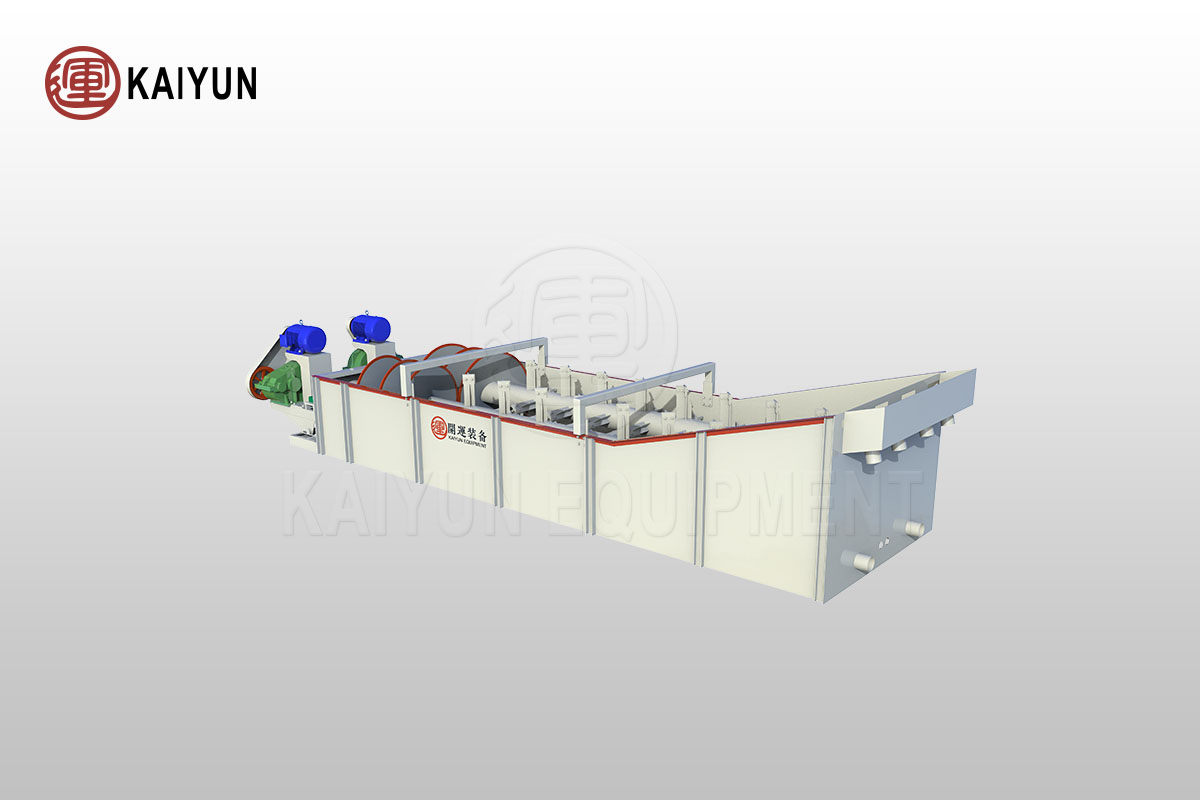

The Spiral Chute Scrubber is an efficient ore washing device that utilizes the difference in settling velocities of solid particles with varying specific gravities in a liquid for mechanical classification.

The Spiral Chute Scrubber is widely used for washing and desliming operations in minerals such as phosphate and iron ores. It is particularly effective in breaking up and dispersing highly cohesive clay lumps, making it an ideal choice for processing ores with low large ore content and high clay content.

However, it is not suitable for handling brittle materials. Kaiyun Intelligent Equipment offers customized services to ensure the equipment perfectly matches actual operating conditions and customer needs.

Table of Contents

Advantages and Features

Simple Operation and Low Maintenance Cost

The Spiral Chute Scrubber features a simple structure, easy installation, low power consumption, intuitive operation, and low manufacturing cost.

Its excellent desliming performance makes it a preferred choice for economically efficient ore washing operations.

Efficient Ore Slurry Separation

The dual-row blades on the spiral shaft effectively stir the ore slurry, breaking up clay-bound ore and separating the clay from the ore. This significantly enhances the desliming effect and ensures the purity of the ore.

Working Principle

The Spiral Chute Scrubber primarily consists of the tank, left and right spiral blade shafts, and the drive system. During operation, the motor drives the two spiral shafts to rotate relative to each other through a reducer and gear system. The blades on the spiral shafts are installed in an interleaved manner.

Materials are fed into the space between the two spiral shafts from the lower part of the tank. Under the action of the rotating blades and the high-pressure water supplied from the upper end of the tank, the ore slurry is agitated and scrubbed, breaking up the clay and separating it from the ore particles. This achieves the goal of ore washing.

The washed fine clay is discharged through the overflow outlet installed at the rear of the tank, while the scrubbed ore is transported by the rotating spiral blades to the discharge port at the front end of the tank. The entire process is efficient and thorough, ensuring the purity and quality of the ore.

Technical Parameters

| Model | Internal Length (mm) | Internal Width (mm) | Capacity (t/h) | Feed Particle Size (mm) | Machine Inclination (°) | Pitch (mm) | Motor Model | Motor Power (kw ) | Weight (kg) |

| SCS1566 | 6660 | 1500 | 35-40 | <75 | 10.84° | 300 | Y200L2-6 | 22 | 15800 |

| SCS1676 | 7630 | 1600 | 40-50 | 10° | Y250M-6 | 37 | 17168 |