Product Description

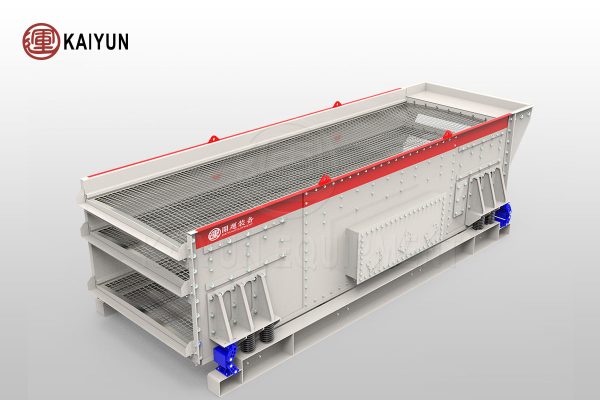

Three-axis horizontal vibrating screen is developed by absorbing the same type of vibrating screen technology at home and abroad. Because it is installed horizontally, it occupies less space on site. It is widely used in metallurgy, building materials, transportation and other industries. It is an ideal equipment for mobile crushing stations.

Three-axis horizontal vibrating screen adopts three-axis drive to make the screen machine produce ideal elliptical motion, combining the respective advantages of circular vibrating screen and linear vibrating screen. The three-layer side arm box increases the maximum stress area, which is suitable for coarse particle screening, natural aggregate and finished product fine screening of crushed aggregate. It has the characteristics of good screening permeability, large processing capacity and small installation height. It is an ideal equipment for various mines, stone quarries and mobile screening stations.

Table of Contents

- Product Description

- Core Advantages and Features

- ⚙️ Triaxial Vibration System

- 📐 Horizontal structure design for more efficient screening.

- 🧱 Suitable for screening high-moisture and high-viscosity materials

- 🏗️ Multi-layer screening + high processing capacity

- 🔩 Modular design for easy maintenance.

- 🌍 Suitable for fixed or mobile screening systems.

- Heavy-duty high-strength screen box

- Fool-style lubrication method

- Forced synchronous three-axis structure

- Help enterprises achieve “carbon neutrality”

- Working principle

- Applications

- Technical Parameters

Core Advantages and Features

⚙️ Triaxial Vibration System

Balanced power and adjustable amplitude provide more stable and reliable vibration.

📐 Horizontal structure design for more efficient screening.

The elliptical screening path effectively improves screening efficiency, especially suitable for wet and sticky materials.

🧱 Suitable for screening high-moisture and high-viscosity materials

Such as coal slime, quartz sand, river sand, and fine iron ore.

🏗️ Multi-layer screening + high processing capacity

Three-axis horizontal vibrating screen,supports 2–4 screen layers for multi-grade separation.

🔩 Modular design for easy maintenance.

Strong vibrator seal structure, long bearing life, and short maintenance cycles.

🌍 Suitable for fixed or mobile screening systems.

Three-axis horizontal vibrating screen widely used in mining, gravel pits, or mobile crushing and screening plants.

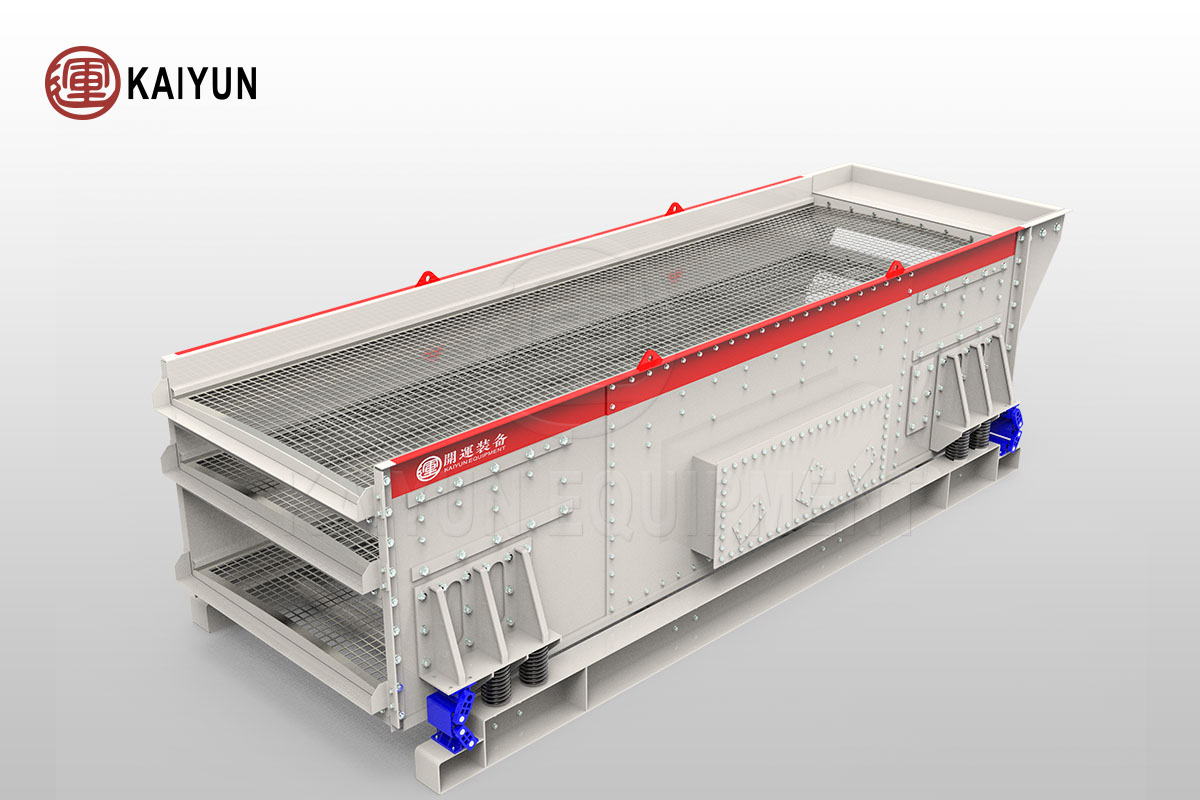

Heavy-duty high-strength screen box

High-strength container steel and fish-shaped frame design greatly enhance durability and screening efficiency.

Fool-style lubrication method

Simplified lubrication system ensures structural stability under heavy-duty operations.

Forced synchronous three-axis structure

Military-grade gears and triple-shaft drive deliver powerful, stable vibration with long-term reliability.

Help enterprises achieve “carbon neutrality”

Energy-saving elliptical motion reduces power use by 58% and extends screen life by 35%, cutting material waste.

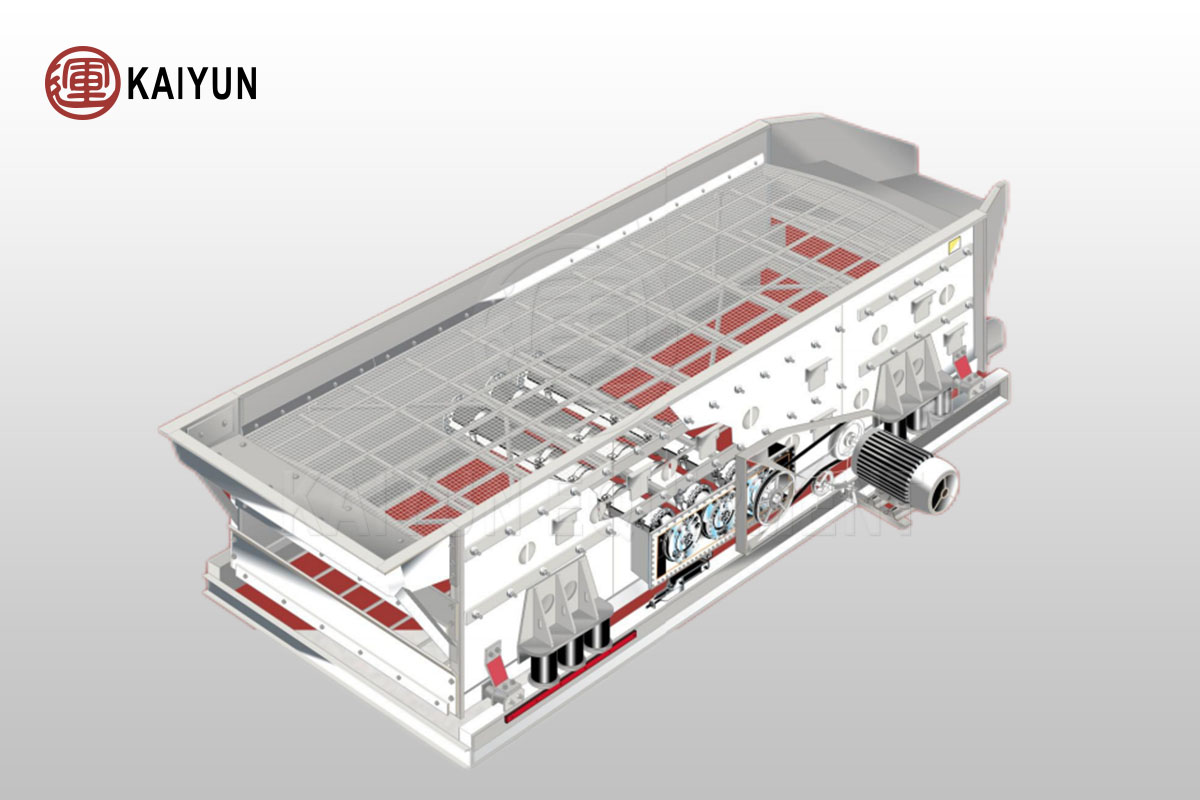

Working principle

The efficient operation of the triple-deck horizontal vibrating screen stems from its precision construction and coordinated driving mechanism. The equipment primarily consists of a motor, transmission device, screen box, rubber springs, base frame, dampers, and other key components.

During operation, power from the motor is transmitted via a V-belt to the drive shaft of the vibrator, which drives the gear vibrator (with a 1:1 speed ratio). The three shafts rotate synchronously, generating powerful vibration force.

The vibrator is securely connected to the screen box using high-strength bolts, causing the screen box to produce elliptical motion.

Material on the screen surface quickly stratifies, screens, and advances forward along the high-speed elliptical trajectory of the screen, efficiently completing material classification and screening tasks.

Applications

Industry Applications

Sand and gravel aggregate production lines (wet/dry screening)

Mine ore/concentrate screening (iron ore, manganese ore, copper ore)

Pre-screening in sand recovery systems

Screening of fine materials such as construction waste, coal slime, and ceramic raw materials

Typical Materials

Quartz sand, manufactured sand, limestone, river sand, iron ore fines, coal slime, ceramic raw materials, tailings slurry, etc.

Technical Parameters

| Model | Rotating speed (r/min) | Screenlayers | Screen size(mm) | Max.Feed size(mm) | Capacity(t/h) | Motor Power(kw) |

| KY502 | 730-850(Speed isadjustable) | 2 | 1560*4800 | 200 | 280-350 | 22 |

| KY503 | 3 | 1560*4800 | 200 | 280-350 | 22 | |

| KY602 | 2 | 1930*6080 | 250 | 280-550 | 30 | |

| KY603 | 3 | 1930*6080 | 250 | 280-550 | 30 | |

| KY702 | 2 | 2235*6080 | 250 | 350-800 | 37 | |

| KY703 | 3 | 2235*6080 | 250 | 350-800 | 37 | |

| KY802 | 2 | 2540*6080 | 250 | 450-1000 | 37 | |

| KY803 | 3 | 2540*6080 | 250 | 450-1000 | 37 | |

| KY900 | 2 | 2845*6096 | 250 | 650-1200 | 55 | |

| KY1000 | 2 | 3170*6096 | 250 | 850-1600 | 55 |