Product Introduction

TX series crawler mobile crusher and screener is the master in the field of crawler mobile hard rock crushing and screening. It creatively integrates four units: vibrating feeder, jaw crusher, multi-cylinder hydraulic cone crusher, and three-layer double-stage screen. Through the sophisticated structural design, it achieves the crushing and screening effect of the split hard rock production line, opening a new journey of mobile hard rock crushing.

Core selling point: hard rock nemesis, creative breakthrough, ultra-high energy efficiency.

Table of Contents

Applicable fields

Secondary and tertiary crushing and screening of medium and high hardness materials.

Hard rock line production with relatively tight site.

Crushing and sand making of highly wear-resistant stones (SiO0 content higher than 75%) such as river pebbles, granite, and diabase in quarries.

Pre-ball milling crushing of iron ore in large ore dressing plants.

Structural advantages

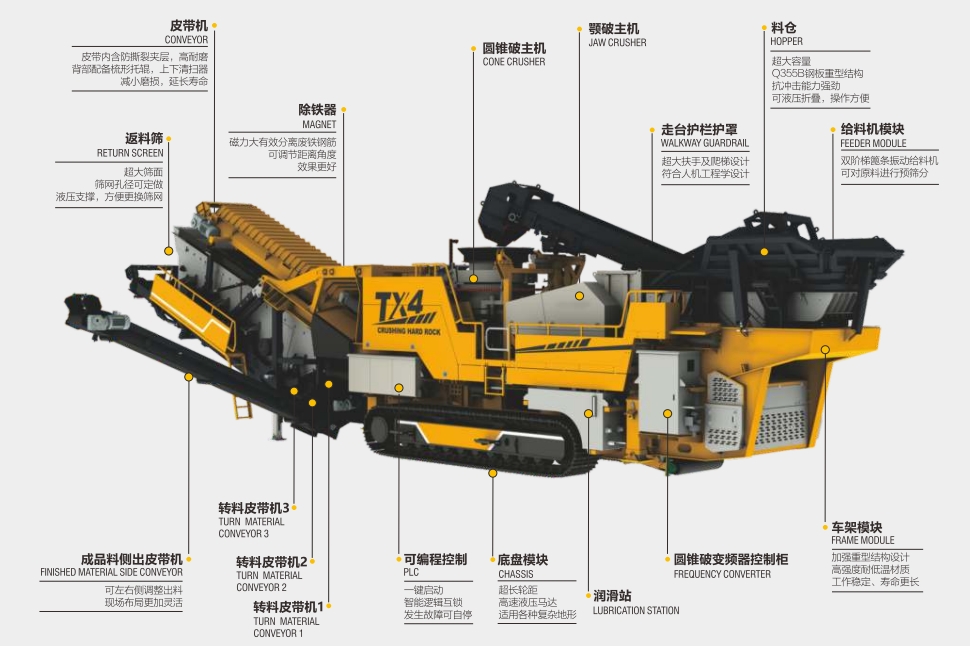

Belt conveyor

The belt contains a tear-resistant interlayer, and the high-wear-resistant back is equipped with comb-shaped rollers. The upper and lower sweepers reduce wear and extend life.

Return screen

Super large screen surface, the screen aperture can be customized. Hydraulic support, convenient replacement of the screen.

Iron remover

The magnetic force is strong, which can effectively separate scrap iron and steel bars, and the distance and angle can be adjusted for better effect.

Walkway guardrail cover

The design of super large handrail and ladder conforms to the ergonomic design.

Binary

Super large capacity, heavy-duty structure of 0355B steel plate, strong impact resistance, hydraulic folding, easy operation.

Feeder module

The double-step grate vibrating feeder can pre-screen the raw materials.

Finished material side conveyor

The discharge can be adjusted on the left and right sides, and the on-site layout is more flexible.

PLC

One-button start, intelligent logic interlocking, automatic stop in case of failure

Chassis module

Extra-long wheelbase, high-speed hydraulic motor, suitable for various complex terrains.

Frame module

Reinforced heavy-duty structure design, high-strength and low-temperature resistant material, stable operation and longer life.

Parameter

| TX4 | |

| Feeding equipment | |

| Feeding height (mm) | 4100 |

| Feeder width x length (mm) | 1100×3737 |

| Motor power (kw) | 2×3.7 |

| Return screen (double stage) | |

| Number of screen layers | 3 |

| Vibrating screen width x length (mm) | 2000×2500/2000×3500 |

| Motor power (kw) | 4×6 |

| Belt conveyor | |

| Main belt conveyor width x height (mm) | 1200×15500 |

| Finished product side belt conveyor width x height (mm) | 500×6125 |

| Under-screen belt conveyor width x height (mm) | 1200×7570 |

| Return belt conveyor 1 width x height (mm) | 1000×9760 |

| Return belt conveyor 2 width x height (mm) | 1000×6260 |

| Complete machine | |

| Complete machine power (kw) | 452 |

| Processing capacity (t/h) | 200-400 |

| Travel speed (km/h) | 0.6-1 |

| Complete machine weight (kg) | 115 |

| Transportation dimensions length x width x height (mm) | 20700x5100x4000 |