Product Introduction

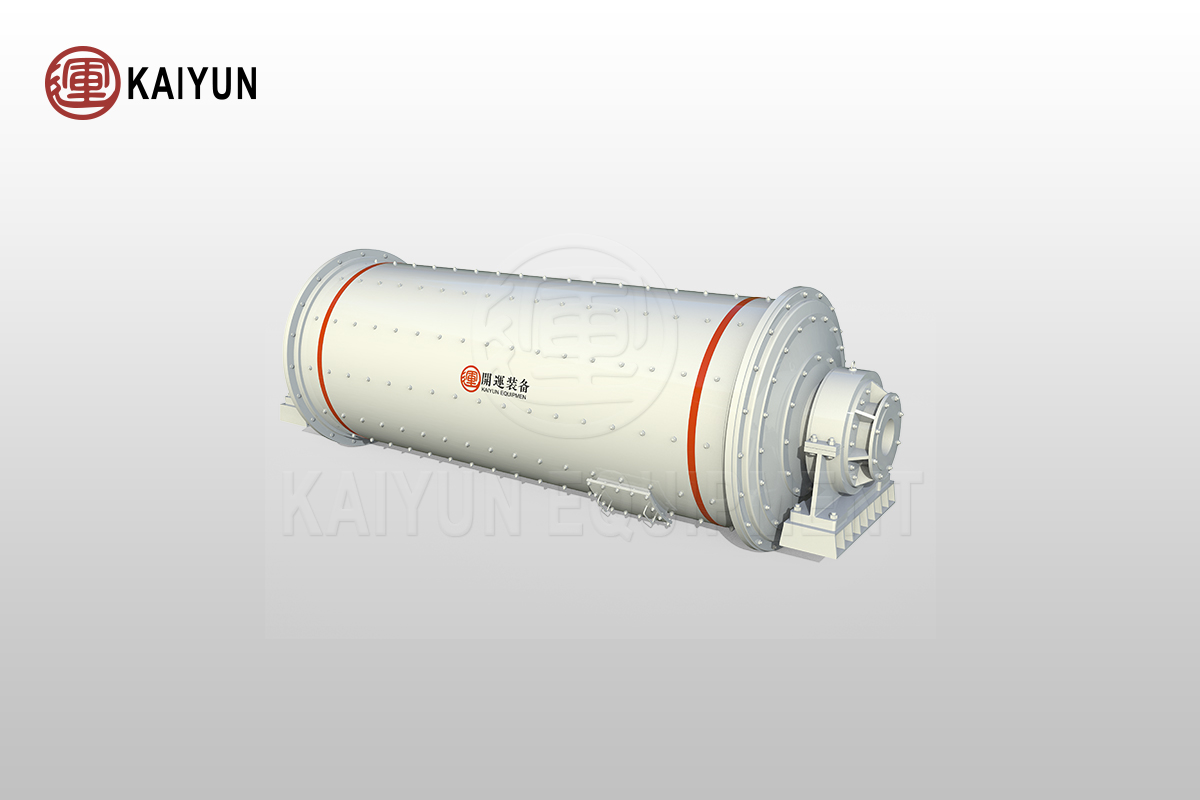

The wet overflow ball mill, a new type of ball mill with a streamlined structure and high energy efficiency, is specifically designed for processing fine-grained ores. Its unique self-flow discharge mechanism represents a revolutionary breakthrough in the mineral processing industry.

Whether in mineral processing, building materials, or chemical industries, the wet overflow ball mill is the ideal choice for enhancing production efficiency and reducing energy consumption, thanks to its outstanding performance and reliability.

Table of Contents

Advantages and Features

Static-Dynamic Bearing System

Utilizes advanced static-dynamic bearing technology to ensure smooth and reliable operation, significantly reducing vibration and noise, and extending the equipment’s lifespan.

Intelligent Hydraulic Lifting Device

The hydraulic lifting function greatly simplifies the maintenance process, making routine upkeep more efficient and quick. This reduces downtime and improves production efficiency.

Flexible Start with Air Clutch

The air clutch enables a soft start, minimizing the impact on the equipment during startup, extending its lifespan, and reducing energy consumption.

Slow-Speed Drive Design

The slow-speed transmission mechanism not only facilitates maintenance operations but also provides additional safety during startup, ensuring a smooth transition to normal operating conditions while saving energy.

Oil Mist Lubrication Technology

The built-in oil mist lubrication system provides comprehensive lubrication for the large and small gears, effectively preventing wear and ensuring long-term stable operation of the drive system.

Wear-Resistant Liner Material

The drum liners can be customized from manganese steel or wear-resistant rubber materials, offering excellent wear resistance, extending equipment life, reducing maintenance costs, and making replacement easier.

Working Principle

The core of the wet overflow ball mill lies in its elongated rotating drum, supported by rolling bearings and driven by a transmission mechanism that causes the drum to rotate slowly. Materials are continuously fed from the feed end. Inside the drum, steel balls and ore are crushed through cascading impacts and self-grinding actions.

As new material is continuously added, the material inside the drum moves naturally from the feed end to the discharge end under pressure. When the slurry level exceeds the lower edge of the hollow shaft at the discharge end, it automatically overflows and exits the mill.

Notably, the hollow shaft is equipped with anti-spiral blades, which effectively guide the overflowing steel balls and coarse ore particles back into the mill, preventing resource waste and ensuring the efficiency and continuity of the grinding process.

Technical Parameters

| Model | Drum Diameter (mm) | Drum Length(mm) | Motor Model | Motor Power (kw) | Length(mm) | Width (mm) | Height(mm) | Volume (m³) | Ball Load (t) | Weight(kg) |

| MQY 0918 | 900 | 1800 | Y225M-8 | 22 | 5080 | 2300 | 2015 | 0.9 | 1.66 | 6078 |

| MQY 1212 | 1200 | 1200 | Y225S-8 | 18.5 | 5788 | 2994 | 2540 | 1.14 | 2.4 | 11473 |

| MQY 1224 | 1200 | 2400 | YR280S-8 | 55 | 6112 | 2794 | 2540 | 2.28 | 3.8 | 12308 |

| MQY 1515 | 1500 | 1500 | JR115-8 | 60 | 5766 | 2945 | 2600 | 2.2 | 6.4 | 15424 |

| MQY 1530 | 1500 | 3000 | JR125-8 | 95 | 7979 | 2945 | 2600 | 5 | 10 | 18690 |

| MQY 2122 | 2100 | 2200 | JR128-8 | 155 | 8070 | 4840 | 3795 | 6.6 | 14 | 47800 |

| MQY 2130 | 2100 | 3000 | JR137-8 | 210 | 8870 | 4840 | 3795 | 9 | 20 | 47220 |

| MQY 2136 | 2100 | 3600 | JR137-8 | 210 | 9300 | 4840 | 3795 | 10.8 | 22 | 52010 |

| MQY 2145 | 2100 | 4500 | JR148-6 | 310 | 11029 | 4739 | 3300 | 13.5 | 23.8 | 58305 |

| MQY 2430 | 2400 | 3000 | JR1410-8 | 280 | 9710 | 4778 | 4120 | 12.1 | 23 | 65880 |

| MQY 2721 | 2700 | 2100 | JR1410-8 | 280 | 9400 | 5600 | 4700 | 10.7 | 24 | 63900 |

| MQY 2736 | 2700 | 3600 | TDMK400-32 | 400 | 13049 | 5800 | 4680 | 17.8 | 32 | 96570 |

| MQY 2740 | 2700 | 4000 | TDMK400-32 | 400 | 11850 | 5667 | 4496 | 20.4 | 40 | 78800 |

| MQY 3231 | 3200 | 3100 | TDMK630-36 | 630 | 12750 | 6760 | 5150 | 21.4 | 45 | 107660 |

| MQY 3245 | 3200 | 4500 | TDMK630-36 | 630 | 14356 | 7200 | 5153 | 32.8 | 65 | 130283 |

| MQY 3254 | 3200 | 5400 | TM1000-36/2600 | 1000 | 15800 | 6760 | 5200 | 37.2 | 73 | 121000 |

| MQY 3645 | 3600 | 4500 | TM1000-36/2600 | 1000 | 15000 | 7200 | 6326 | 41.8 | 76 | 135000 |

| MQY 3650 | 3600 | 5000 | TM1250-40/3250 | 1250 | 17157 | 7755 | 6326 | 46.4 | 86 | 145000 |

| MQY 3660 | 3600 | 6000 | TM1250-40/3250 | 1250 | 19000 | 7755 | 6326 | 55.7 | 102 | 154000 |

| MQY 3690 | 3600 | 9000 | TDMK1800-30 | 1800 | 28000 | 4600 | 5600 | 83 | 163 | 212000 |

| MQY 3867 | 3800 | 6700 | TDMK1600-30 | 1600 | 19000 | 8200 | 7100 | 70 | 130 | 186000 |

| MQY 4067 | 4000 | 6700 | TDMK1800-30 | 1800 | 15600 | 9600 | 7300 | 78 | 138 | 207000 |

| MQY 4561 | 4500 | 6100 | TDMK2200-30 | 2200 | 18200 | 10500 | 7600 | 93 | 151 | 238000 |