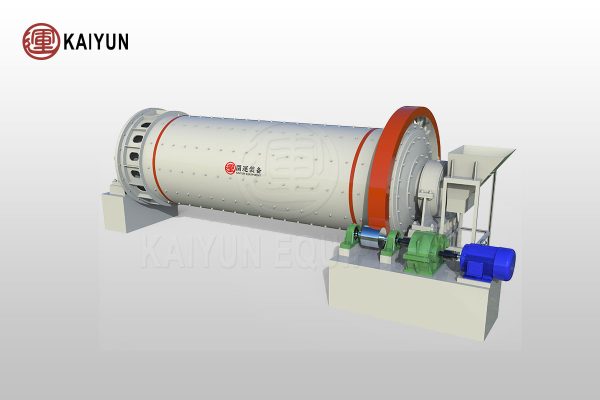

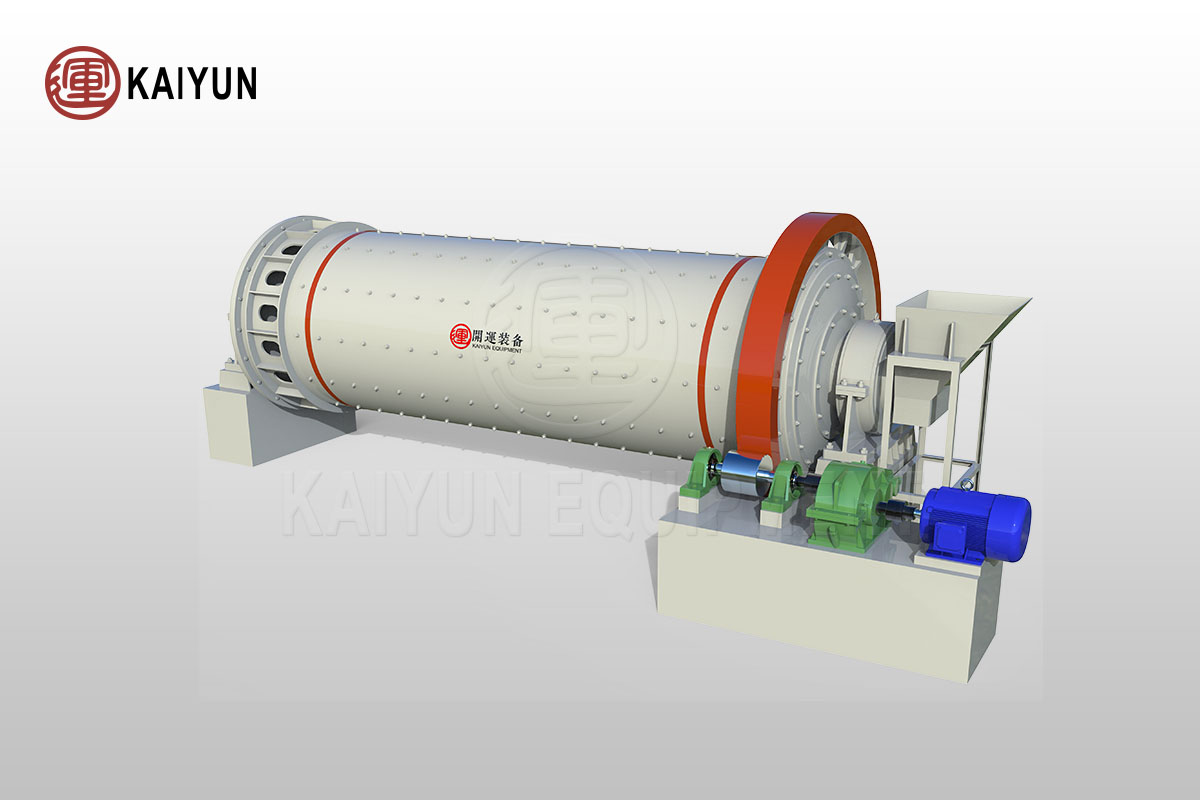

Product Introduction

The wet rod mill, designed specifically for coarse grinding operations, provides an efficient and precise solution for the fine and coarse grinding of ores with its unique steel rod grinding medium.

Especially effective in the primary open-circuit grinding of brittle materials, the wet rod mill demonstrates unparalleled advantages by ensuring uniform particle size and reducing over-grinding. It is an indispensable tool in the mineral processing field.

Table of Contents

Advantages and Features

Consistent Rod Movement

The conical end cover design of the wet rod mill provides a more regular trajectory for the steel rods within the mill, ensuring efficient and stable grinding operations.

Convenient Maintenance and Discharge

The increased diameter of the discharge hollow shaft facilitates easier routine maintenance and effectively reduces the slurry liquid level, accelerating ore discharge and improving production efficiency.

Precise Particle Size Control

Typically, the wet rod mill handles feed sizes ranging from 20 to 30 mm, with product sizes usually reaching 0 to 3 mm, demonstrating precise control over particle size.

Uniform Grinding Effect

The full length of the steel rods participates in grinding, with evenly distributed forces ensuring consistent particle size and reducing unnecessary over-grinding, thereby enhancing ore utilization.

Working Principle

The working principle of the wet rod mill is similar to most grinding equipment, but it uniquely uses steel rods as the grinding medium. Driven by a motor through a reducer and surrounding large gear, or directly by a low-speed synchronous motor driving the large gear, the drum slowly rotates. Inside the drum, a suitable amount of steel rods are lifted to a certain height by centrifugal and frictional forces and then fall by cascading or spilling, delivering powerful crushing to the material entering the drum.

During continuous feeding, the material is crushed by the moving steel rods. It is then discharged from the mill through overflow or open-end discharge methods, entering the next stage of processing.

The wet rod mill uses either overflow or open-end discharge methods. The discharge hollow shaft has a larger diameter compared to ball mills of the same specification. This allows the wet rod mill to serve as an alternative to short-head cone crushers when processing ores of moderate hardness or softer ores (especially those with high viscosity). It can finely grind ores from 19-30 mm to 6-12 mesh particle size. Compared to a closed-circuit system with a cone crusher and screening equipment, the wet rod mill offers a simpler configuration and lower cost, providing a more economical and efficient option for mineral processing.

Technical Parameters

| Model | Drum Diameter(mm) | Drum Length (mm) | Motor Model | Motor Power (kw) | Motor Speed (r/min) | L*W*H (mm) | Capacity (t/h) | Volume (m³) | Weight (kg) |

| MBY 0918 | 900 | 1800 | Y225M-8 | 22 | 730 | 4980*2370*2020 | 0.62~3.2 | 0.9 | 5700 |

| MBY 0924 | 900 | 2400 | Y250M-8 | 30 | 730 | 5670*3280*2020 | 0.81~4.3 | 1.2 | 5880 |

| MBY 1224 | 1200 | 2400 | Y280M-8 | 45 | 730 | 6450*2800*2500 | 0.4~4.9 | 2.28 | 12308 |

| MBY 1530 | 1500 | 3000 | JR125-8 | 95 | 725 | 7935*3185*2280 | 0.4~4.9 | 5 | 19990 |

| MBYG 1530 | 1500 | 3000 | JR117-8 | 80 | 725 | 7253*3070*2280 | 2.4~7.5 | 5 | 21210 |

| MBYG 2130 | 2100 | 3000 | JR136-8 | 180 | 735 | 8122*4220*3073 | 14~35 | 9 | 42123 |

| MBYG 2136 | 2100 | 3600 | JR137-8 | 210 | 735 | 8958*4320*3025 | 43~61 | 10.8 | 45800 |

| MBYG 2430 | 2400 | 3000 | JR138-8 | 280 | 735 | 9005*4836*3490 | 43~61 | 11.5 | 55795 |

| MBYG 2732 | 2700 | 3200 | JR157-8 | 320 | 750 | 10509*5000*3620 | 43~61 | 15.7 | 83110 |

| MBYG 2736 | 2700 | 3600 | JR158-8 | 380 | 743 | 10764*5750*3620 | 32~86 | 17.7 | 90441 |

| MBY 2740 | 2700 | 4000 | TDMK400-32 | 400 | 187.5 | 12300*5700*4700 | 43~110 | 20.4 | 75000 |

| MBY 3040 | 3000 | 4000 | JR1510-8 | 570 | 740 | 9800*3900*3900 | 54~135 | 26 | 90000 |

| MBY 3245 | 3200 | 4500 | TDMK800-36 | 800 | 167 | 14600*7000*5300 | 64~180 | 31 | 113000 |

| MBY 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 150 | 15200*8800*6800 | 80~230 | 41.8 | 139000 |

| MBY 3654 | 3600 | 5400 | TDMK1600-40 | 1600 | 150 | 15900*8800*6800 | 100~250 | 49.7 | 150000 |