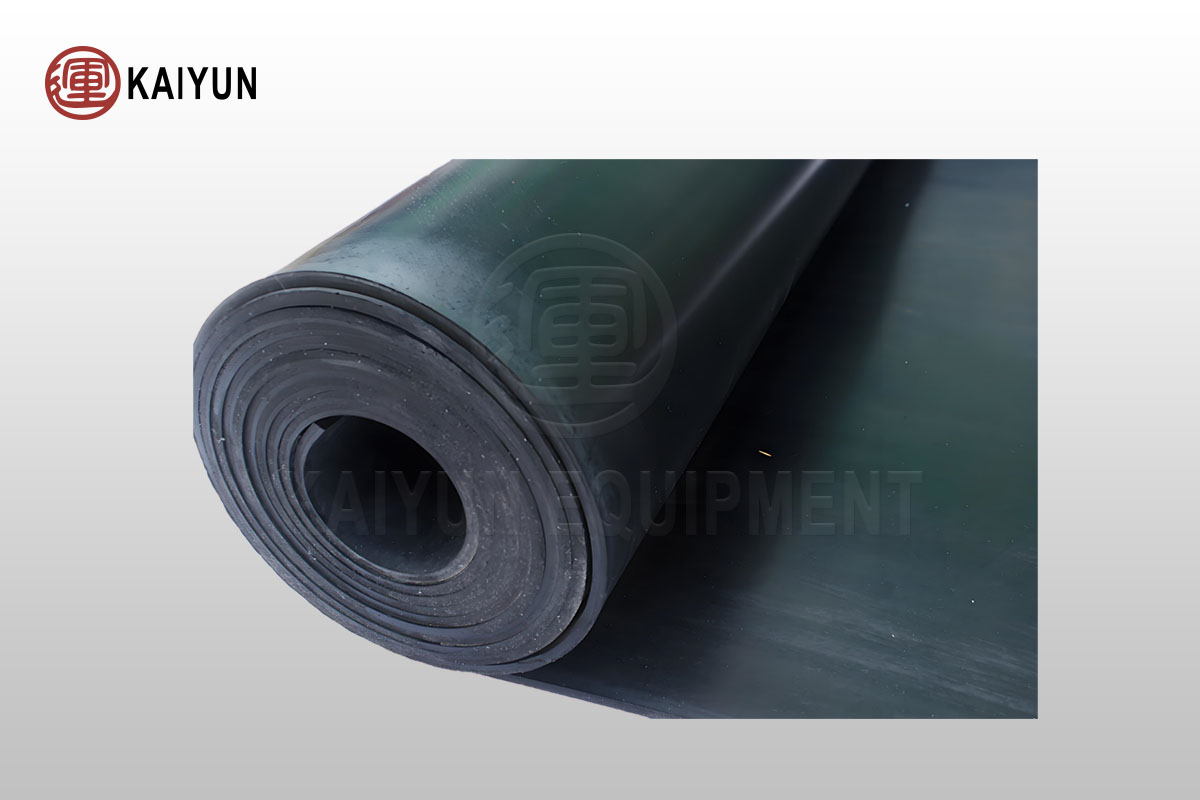

Product Introduction

Wet Wear-Resistant Rubber Sheet is a high-performance rubber material developed using the revolutionary “Liquid Nano Formulation • Ambient Temperature High-Frequency Curing” rubber compounding technology. This innovative process not only breaks the long-standing foreign technological monopoly in the field of liquid rubber compounding but also marks a significant step forward in China’s research and development of wear-resistant rubber materials.

Table of Contents

Core Advantages and Features

Exceptional Wear Resistance

The wet wear-resistant rubber sheet boasts outstanding wear resistance, with a wear index reaching up to 128%. This means its wear life significantly exceeds that of traditional rubber materials under the same conditions, making it particularly suitable for high-wear environments.

Excellent Resilience

With a rebound rate of 80%, the material exhibits excellent recovery ability. Even under heavy pressure or impact, it quickly returns to its original shape, reducing the risk of permanent deformation.

High Strength and Tear Resistance

The tensile strength reaches 23.5 MPa, and the tear strength is 168 N/mm. This indicates that the material not only has high strength but also maintains structural integrity when subjected to tearing forces, making it resistant to damage.

These features make the wet wear-resistant rubber sheet an ideal material choice, especially for applications requiring high wear resistance, rebound, and tear resistance in wet conditions. This includes industries such as ore processing, chemical production, and wastewater treatment, where it can significantly enhance equipment efficiency and service life, particularly in components like pumps, valves, and pipe linings.