Product Introduction

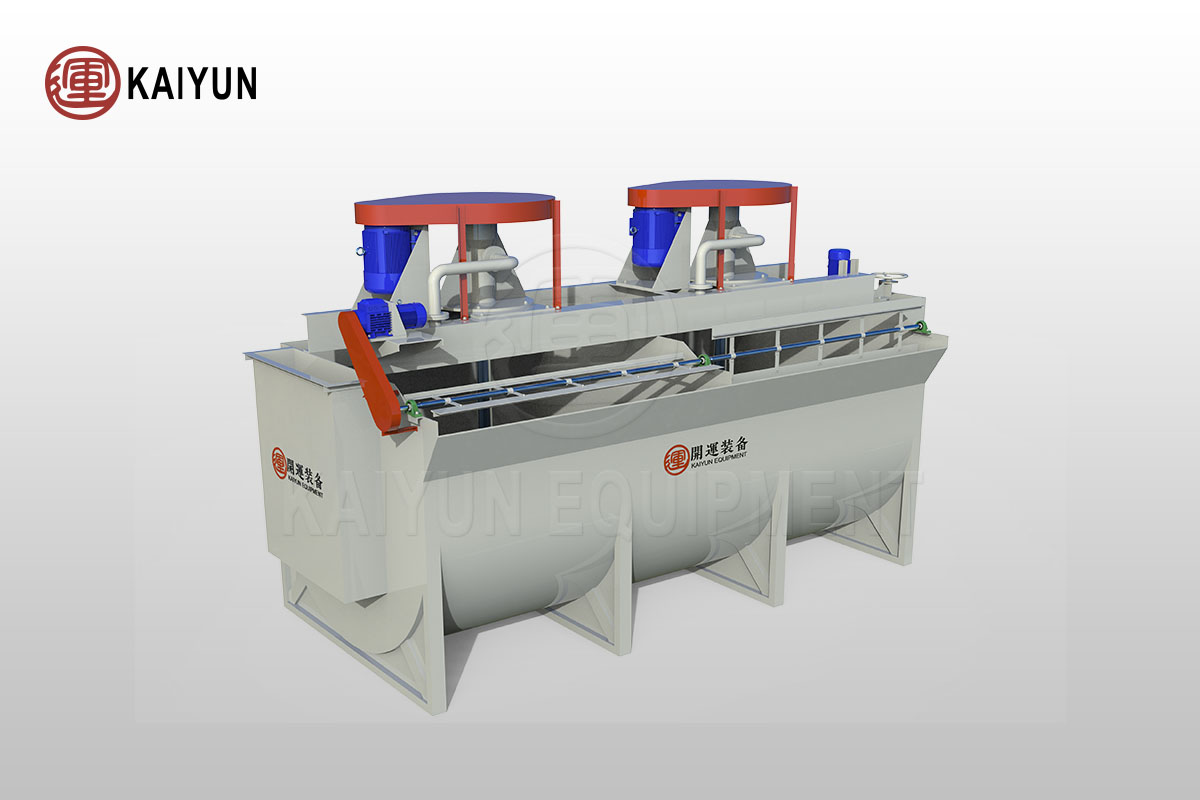

The XCF type air-lift stirring flotation machine is an advanced self-aspirating, air-lift mechanical stirring flotation device, designed specifically for the separation of non-ferrous metals, ferrous metals, and non-metallic minerals. It is particularly well-suited for rough and scavenging flotation processes in large and medium-sized flotation plants.

The XCF type air-lift stirring flotation machine innovative design features, including the impeller and stator, along with optimized fluid dynamics, and the use of high-performance materials and processing techniques, offer significant advantages in terms of wear uniformity, service life, maintenance convenience, and reduced tailings accumulation.

Table of Contents

Advantages and Features

Optimized Fluid Dynamics Design

The innovative design of the impeller and stator strictly adheres to the principles of flotation machine fluid dynamics. This ensures effective mixing and stable flow of slurry and air, enhancing flotation efficiency.

High-Performance Materials and Craftsmanship

Utilizes premium materials and advanced processing techniques to ensure minimal and uniform wear on critical components such as the impeller and stator, significantly extending the equipment’s service life.

Convenient Maintenance and Low Repair Needs

The design focuses on ease of operation and maintenance, greatly reducing the maintenance workload and lowering operational costs.

U-shaped trough structure optimization

The U-shaped trough design effectively reduces tailings deposition, ensures the cleanliness of the slurry in the trough, and improves the efficiency of the flotation process and product quality.

Working Principle

The working principle of the XCF aerated agitator flotation machine is based on the combination of the negative pressure effect generated by the rotation of the impeller and the low-pressure air provided by the blower. When the impeller rotates, its upper blades suck the slurry from all around, and at the same time, the air sent by the blower enters between the lower blades of the impeller through the distributor and is fully mixed with the slurry.

The mixed slurry and air are discharged from the periphery of the lower blades of the impeller, and enter the main slurry in the tank after being stabilized and oriented by the stator. The mineralized bubbles formed rise to the surface of the tank to form a foam layer, which overflows through the overflow tank to separate the concentrate from the tailings. Part of the slurry in the tank returns to the lower blades of the impeller for recirculation, and the rest enters the next tank through the flow holes for continued sorting.

Technical Parameters

| Model | Volume (m³) | Capacity (m³/min) | Impeller diameter (mm) | Impeller speed(r/min) | Blower air pressure(Kpa) | Upper limit of air volume(m3/m2-min) | Stirring motor power (kw) | Scraper motor power (kw) | Weight (kg) |

| XCF-1 | 1 | 0.2~1 | 400 | 358 | > 12.6 | 2 | 5.5 | 0.75 | 1154 |

| XCF-2 | 2 | 0.4~2 | 470 | 305 | > 14.7 | 2 | 7.5 | 1.1 | 1659 |

| XCF-3 | 3 | 0.6~3 | 540 | 266 | > 19.8 | 2 | 11 | 1.5 | 2259 |

| XCF-4 | 4 | 1.2~4 | 620 | 225 | > 19.8 | 2 | 15 | 1.5 | 2669 |

| XCF-8 | 8 | 3.0~8 | 720 | 175 | > 21.6 | 2 | 22 | 1.5 | 3868 |

| XCF-10 | 10 | 4~10 | 720 | 192 | > 21.6 | 2 | 30 | 1.5 | 4800 |

| XCF-16 | 16 | 4~16 | 860 | 160 | > 25.5 | 2 | 37 | 1.5 | 6520 |

| XCF-24 | 24 | 4~24 | 950 | 153 | > 30.4 | 2 | 37 | 1.5 | 8000 |

| XCF-38 | 38 | 10 ~38 | 1050 | 136 | > 34.3 | 2 | 55 | 1.5 | 11000 |