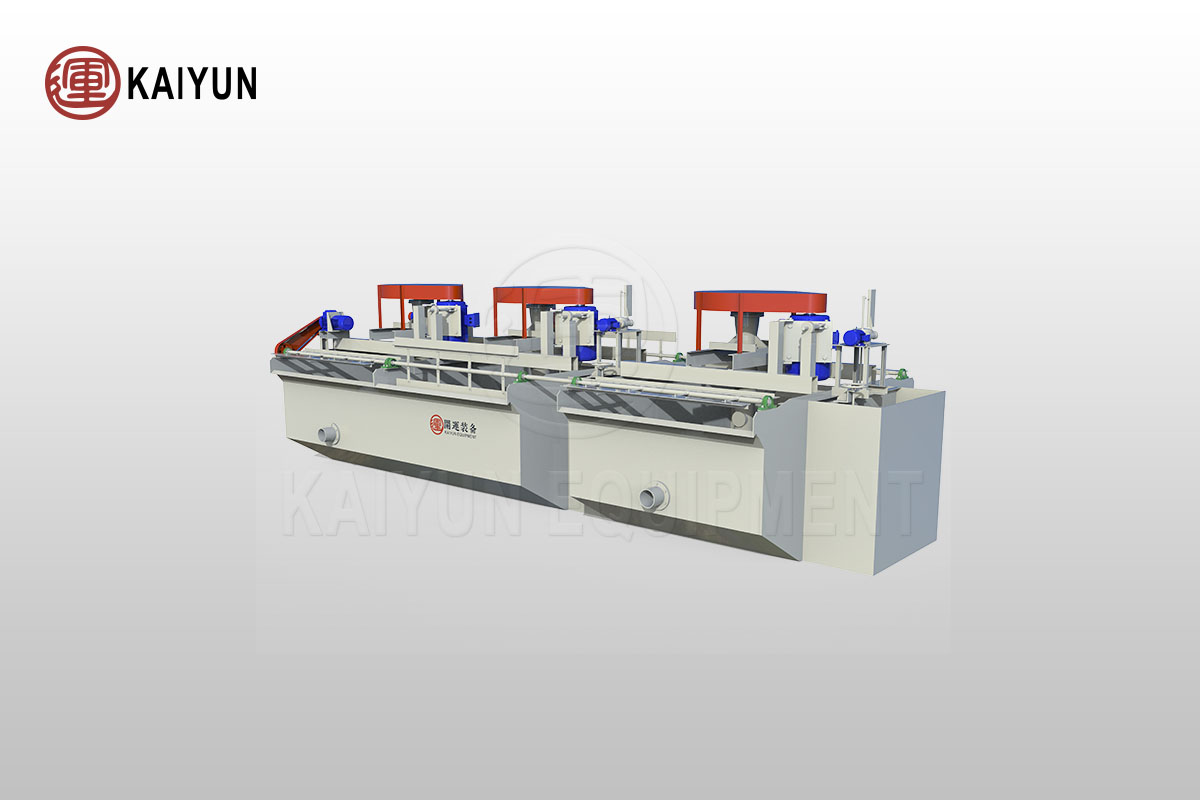

Product Introduction

The XJB rod-type flotation machine, a self-aspirating mechanical stirring flotation device, is the ideal choice for medium and small-scale beneficiation plants dealing with dense and coarse metal ores. Its unique rod wheel design and powerful stirring capabilities make it well-suited for the separation of lead, zinc, copper, molybdenum, sulfur, and silica sand. The XJB rod-type flotation machine demonstrates outstanding performance and versatility across various flotation operations, providing a reliable solution for diverse flotation tasks.

Table of Contents

Advantages and Features

Powerful Stirring and Optimized Slurry-Air Movement

The XJB rod-type flotation machine excels in its stirring capability, effectively handling dense, fast-settling, and coarse mineral materials. This ensures efficient mixing and dispersion during the flotation process. The unique slurry-air movement trajectory design further enhances flotation performance.

Innovative flow stabilizer design

The flow stabilizer, which is composed of multiple arc-shaped blades of different lengths welded to the bottom lining of the tank, can ensure that the slurry-gas mixture is evenly distributed in the tank, while preventing the slurry from rotating, providing stable conditions for flotation.

High Air-inflation Capacity and Strong Stirring Power

This flotation machine features a large air-inflation capacity and powerful stirring force, producing highly dispersed bubbles. This ensures uniform mixing of slurry, air, and reagents, speeds up flotation, and improves beneficiation efficiency.

Diverse Model Options

The XJB rod-type flotation machine is available in various models, catering to different scales and needs of beneficiation operations, offering users flexible configuration options.

Working Principle

The core working principle of the XJB rod flotation machine is to use the negative pressure generated by the rotation of the impeller or rod wheel to suck air from the hollow shaft and divide it through the flotation wheel to form tiny bubbles. The strong stirring and ejection effect of the impeller or rod wheel makes the slurry and air fully mixed to form a slurry-gas mixture. Under the action of the inclined rod of the flotation wheel, the useful mineral particles treated with the flotation agent (collector) selectively attach to the bubbles, float to the surface of the slurry with the bubbles, and are scraped into the concentrate tank by the scraper. Complete the sorting operation.

Technical Parameters

| Model | Slot type | Effective Volume (m³) | Processing Capacity (m³/min) | Impeller diameter (mm) | Impeller speed (r.p.m) | Stirring motor power (kw) | Scraper motor power (kw) | Single Tank Weight (kg) |

| XJB-1 | Suction | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5344 |

| XJB-1 | Direct | 1 | 1.5-1.7 | 410 | 410 | 4 | 0.8 | 5344 |

| XJB-1D | Suction | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5479 |

| XJB-1D | Direct | 1 | 1.5-1.7 | 410 | 410 | 4 | 0.8 | 5479 |

| XJB-2 | Suction | 2 | 1.5-1.4 | 450 | 360 | 15 | 1.1 | 9071 |

| XJB-2 | Direct | 2 | 1.5-1.4 | 540 | 360 | 11 | 1.1 | 9071 |

| XJB-2D | Suction | 2 | 1.5-1.4 | 450 | 360 | 15 | 1.1 | 9320 |

| XJB-2D | Direct | 2 | 1.5-1.4 | 540 | 360 | 11 | 1.1 | 9320 |

| XJB-4 | Suction | 4 | 2.0-4 | 700 | 280 | 18.5 | 1.1 | 16325 |

| XJB-4 | Direct | 4 | 2.0-4 | 510 | 280 | 18.5 | 1.1 | 16325 |