Product Introduction

Zinc oxide rotary kiln is a special heat treatment equipment for zinc oxide production. It is mainly used for high-temperature treatment such as roasting and calcining of raw materials such as zinc concentrate, zinc slag, and zinc waste to obtain zinc oxide products.

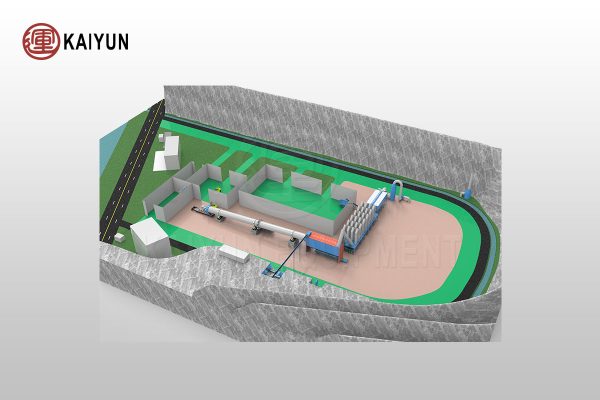

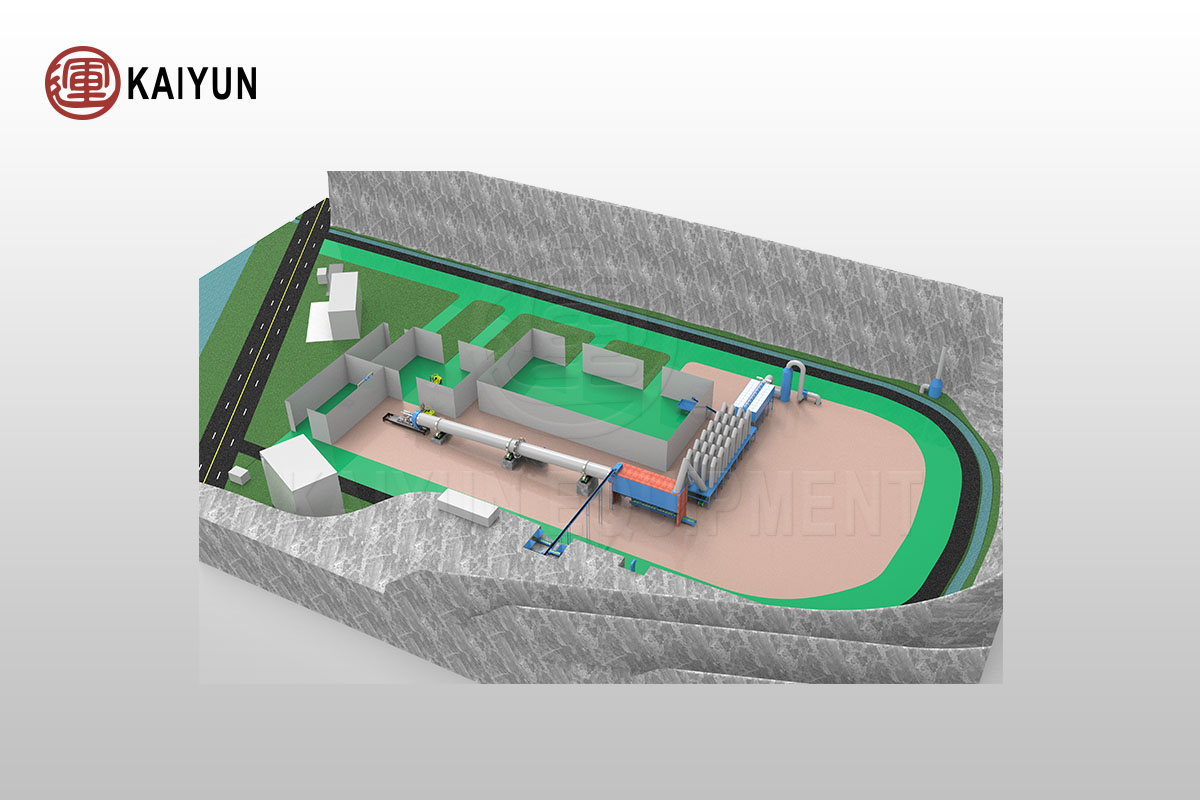

Zinc oxide rotary kiln is mainly composed of cylinder, supporting device, driving system, combustion device, feeding and discharging device, environmental protection system and other structures.

Zinc oxide, as an important chemical raw material, is widely used in rubber, ceramics, medicine, paint, batteries and other fields, and zinc oxide rotary kiln is an indispensable equipment in its production process.

Table of Contents

Application fields

Metallurgical industry

Used for the roasting of zinc concentrate, zinc slag, zinc waste, etc. to produce zinc oxide.

Chemical industry

Zinc oxide is widely used in rubber, coatings, ceramics and other fields as a catalyst or additive.

Environmental protection field

Zinc oxide rotary kiln can also be used to treat zinc-containing waste, recycle zinc resources, and reduce environmental pollution.

Other applications

Zinc oxide, as a functional material, is also widely used in glass, medicine, electronics and other fields.

Working Principle

Zinc oxide rotary kiln is a rotating cylinder equipment with a certain inclination angle. It oxidizes the zinc component in the raw material into zinc oxide through a high-temperature roasting process.

The specific working principle is as follows:

1. Feeding: The raw material is fed into the kiln head of the rotary kiln through the feeding device.

2. Heating and roasting: In the kiln, the raw material is subjected to the action of the high-temperature heat source, undergoes an oxidation reaction, and zinc combines with oxygen to form zinc oxide.

3. Cooling: The roasted material moves to the end of the kiln as the kiln body rotates, gradually cools down and is discharged out of the kiln through the cooling device.

4. Exhaust gas treatment: The exhaust gas generated during the roasting process passes through a special dust removal device and an environmental protection treatment device to avoid the emission of harmful gases and dust.

Advantages

1. High efficiency and energy saving: The rotary kiln is scientifically designed, which can effectively improve the utilization rate of thermal energy and reduce fuel consumption.

2. High degree of automation: Modern zinc oxide rotary kilns are equipped with automatic control systems that can monitor parameters such as temperature and airflow in real time to ensure stable processes.

3. Superior environmental performance: Equipped with efficient dust removal systems and tail gas treatment devices to reduce harmful emissions and meet environmental standards.

4. Stable product quality: Through precise temperature control and continuous rotary operation, the zinc oxide produced is ensured to be of high purity and stable quality.

5. Strong adaptability: The process parameters of the rotary kiln can be adjusted according to different raw materials and production requirements to meet the roasting requirements of different materials.