Product Overview

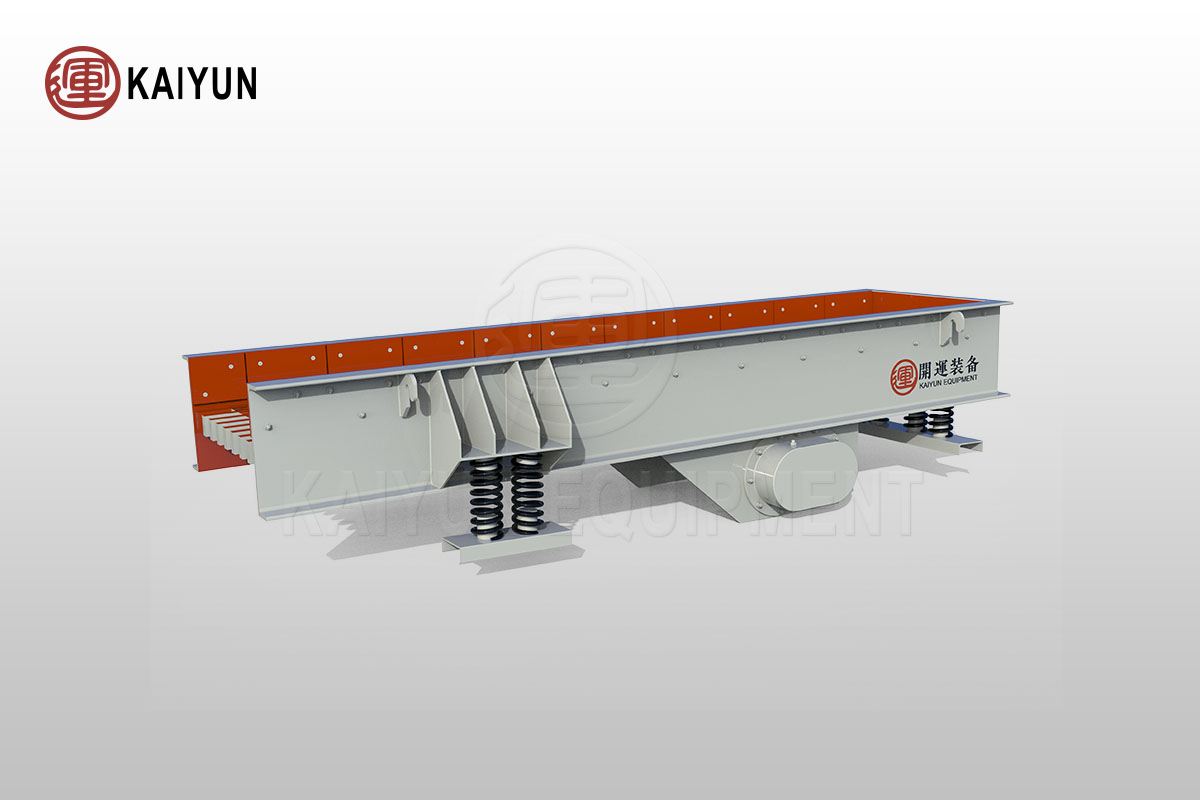

ZSW Vibrating Feeder is a versatile mechanical device designed to handle both coarse screening and continuous, uniform feeding. It is specifically engineered to meet the needs of industries such as metallurgy, coal mining, beneficiation, building materials, chemicals, and abrasives.

ZSW Vibrating Feeder unique dual-eccentric shaft exciter structure not only withstands the impact of large material drops but also delivers outstanding feeding capability. This ensures that materials are evenly, timely, and continuously conveyed from the storage bin to the receiving equipment, seamlessly integrating into automated production processes.

Table of Contents

Advantages and Features

Ingenious Design and Stable Performance

The vibrating feeder features a streamlined structure that is easy to install, operates smoothly, and offers reliable performance with a long service life. Its design facilitates maintenance and repair, providing a solid foundation for integration into automated control systems.

Dual-Eccentric Vibrator and Efficient Screening

Utilizing a dual-eccentric shaft vibrator, the feeder achieves linear vibration. This not only enhances feeding efficiency but also incorporates a screening process during feeding, effectively increasing equipment utilization and reducing operating costs.

Intelligent Adjustment and Precise Feeding

Optional frequency conversion motors allow for frequency adjustment according to production needs, ensuring uniform and accurate material feeding. This feature supports continuous operation of crushers and improves overall production efficiency.

Durable Materials and Grizzly Design

Constructed from high-grade steel, the feeder exhibits excellent tear resistance and bending strength. The adjustable gap design of the grizzly prevents material blockage, ensuring stable and reliable screening performance.

Working Principle

The core working principle of the ZSW Vibrating Feeder lies in its unique dual-eccentric shaft exciter design. Two eccentric shafts, which are engaged through gears and must be aligned during assembly, are driven by a motor to rotate. This rotation generates a combined linear excitation force, causing the feeder body to vibrate on supporting springs.

Driven by this vibration, the material undergoes a sliding and throwing motion within the feed trough, facilitating forward transportation. Simultaneously, as the material passes through the grizzly bars on the trough, smaller particles can drop directly through the gaps without undergoing additional crushing processes. This not only achieves a screening effect but also significantly enhances production efficiency and material handling flexibility.

Technical Parameters

| Model | Trough size (mm) | Upper limit of feeding size (mm) | Feeding capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kw) | Weight (kg) |

| ZSW-380*95 | 3800×950 | 500 | 96-160 | 800 | 11 | 4082 |

| ZSW-420*110 | 4200×1100 | 580 | 120-240 | 800 | 15 | 4149 |

| ZSW-490*96 | 4900×960 | 500 | 120-240 | 800 | 15 | 5351 |

| ZSW-490*110 | 4900×1100 | 630 | 120-280 | 800 | 15 | 5352 |

| ZSW-590*110 | 5900×1100 | 630 | 350-500 | 800 | 22 | 6130 |

| ZSW-600*130 | 6000×1300 | 750 | 400-560 | 800 | 22 | 7800 |