In gold mining operations, efficient grinding is the foundation of high recovery rates. No matter how advanced the downstream separation equipment is, poor grinding performance will directly limit gold liberation and overall plant profitability.

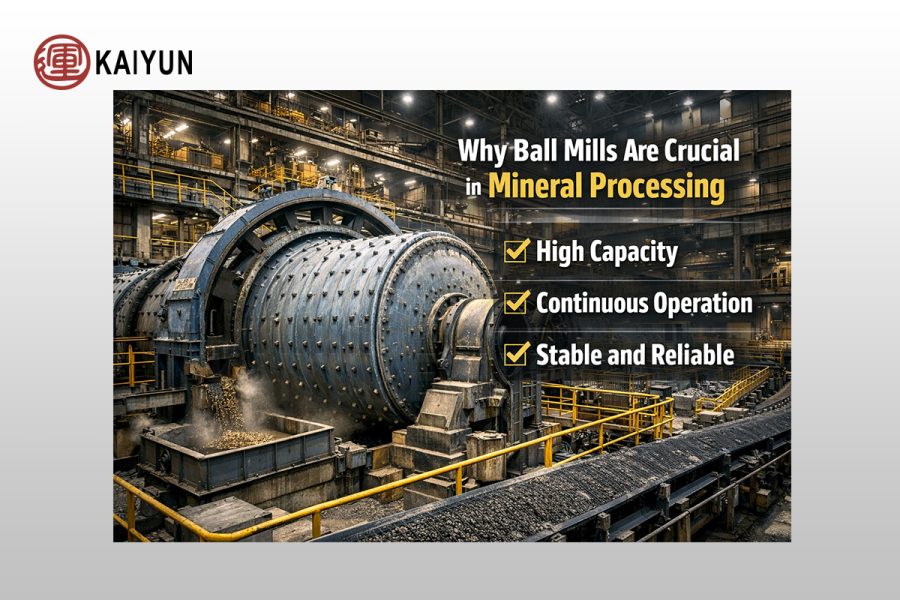

That is why ball mills play a crucial role in modern gold processing plants.

Why Grinding Is Critical in Gold Ore Processing

Gold ore does not exist as free particles in most deposits. Instead, gold is often locked within quartz, sulfides, or complex host rocks.

The purpose of grinding is to:

Liberate gold particles from the surrounding gangue

Achieve the optimal particle size for gravity separation, flotation, or leaching

Ensure stable and continuous downstream processing

Among various grinding solutions, ball mills remain the most widely used and reliable equipment in gold mining.

What Is a Ball Mill?

A ball mill is a rotating cylindrical grinding machine filled with steel balls. As the mill rotates, the balls fall and impact the ore, crushing and grinding it into fine particles.

Ball mills are commonly used in:

Primary grinding after crushing

Secondary grinding in closed-circuit systems

Regrinding before flotation or cyanidation

Key Advantages of Ball Mills in Gold Mining

1. High Grinding Efficiency

Ball mills provide uniform particle size distribution, which is critical for gold liberation. Proper grinding significantly improves:

Gravity gold recovery

Flotation concentrate grade

Leaching efficiency in CIL / CIP systems

2. Continuous and Stable Operation

Gold processing plants often operate 24/7. Ball mills are designed for:

Continuous feeding and discharge

Long service life under heavy load

Stable performance in harsh mining environments

This makes them ideal for medium and large-scale gold mining projects.

3. Strong Adaptability to Different Gold Ores

Ball mills can handle:

Quartz vein gold ore

Alluvial and placer gold ore (after crushing)

Sulfide gold ore

Hard and abrasive materials

By adjusting steel ball size, rotation speed, and liner design, ball mills can be optimized for different ore characteristics.

4. Perfect Compatibility with Downstream Equipment

Ball mills are commonly combined with:

Spiral classifiers or hydrocyclones

Centrifugal concentrators

Shaking tables

Leaching tanks

This flexibility allows engineers to design complete gold processing flowsheets tailored to specific project requirements.

Ball Mill vs Other Grinding Equipment in Gold Processing

| Equipment Type | Suitability for Gold Mining | Key Limitation |

| Ball Mill | Excellent | Requires proper liner and media selection |

| Rod Mill | Moderate | Less effective for fine grinding |

| Vertical Mill | Limited | Higher initial investment |

| Hammer Mill | Poor | Unstable particle size |

For most gold mining applications, ball mills offer the best balance between cost, efficiency, and reliability.

How to Select the Right Ball Mill for a Gold Mine

When choosing a ball mill, the following factors must be considered:

Ore hardness and feed size

Required grinding fineness

Processing capacity (TPH)

Wet or dry grinding

Power consumption and operating cost

A properly selected ball mill can significantly reduce energy consumption while increasing gold recovery.

Complete Gold Processing Solutions Matter More Than a Single Machine

It is important to understand that gold mining cannot be completed by a single machine.

A ball mill must be integrated into a well-designed processing line, including crushing, classification, and gold recovery equipment.

Working with an experienced manufacturer ensures:

Correct equipment matching

Stable plant operation

Faster return on investment (ROI)

Partner with a Reliable Ball Mill Manufacturer

As a professional supplier of mineral processing equipment, we provide:

Customized ball mill design for gold mining projects

Complete gold processing plant solutions

Technical support from layout design to commissioning

Reliable equipment for African and global markets

Looking to Improve Your Gold Recovery?

📩 Contact us today to get:

Ball mill technical specifications

Complete gold processing flowsheet

Competitive quotation and delivery plan