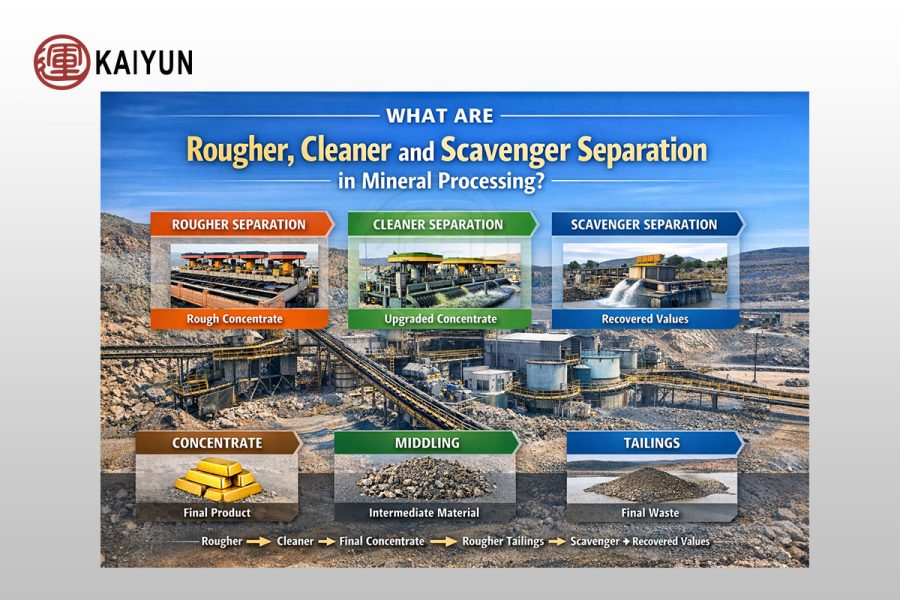

In mineral processing, rougher, cleaner and scavenger separation are fundamental stages used to maximize valuable mineral recovery and improve concentrate quality.

Rougher Separation in Mineral Processing

Rougher separation is the first separation stage for raw ore or ground ore.

It produces rough concentrate and rougher tailings and focuses on high recovery rather than high grade.

Cleaner Separation in Mineral Processing

Cleaner separation upgrades rough concentrate by removing gangue minerals.

Multiple cleaner stages may be applied depending on ore properties and required concentrate grade.

Scavenger Separation in Mineral Processing

Scavenger separation treats rougher tailings to recover remaining valuable minerals and reduce losses to tailings.

What Is Concentrate, Middling and Tailings?

Concentrate: final valuable mineral product

Middling: intermediate material returned for regrinding or re-separation

Tailings: final waste with minimal valuable minerals

Mineral Processing Flowsheet Overview

Rougher → Cleaner → Final Concentrate

Rougher Tailings → Scavenger → Recovered Values

Summary

Understanding rougher, cleaner and scavenger separation helps improve plant recovery, reduce losses, and optimize mineral processing performance.