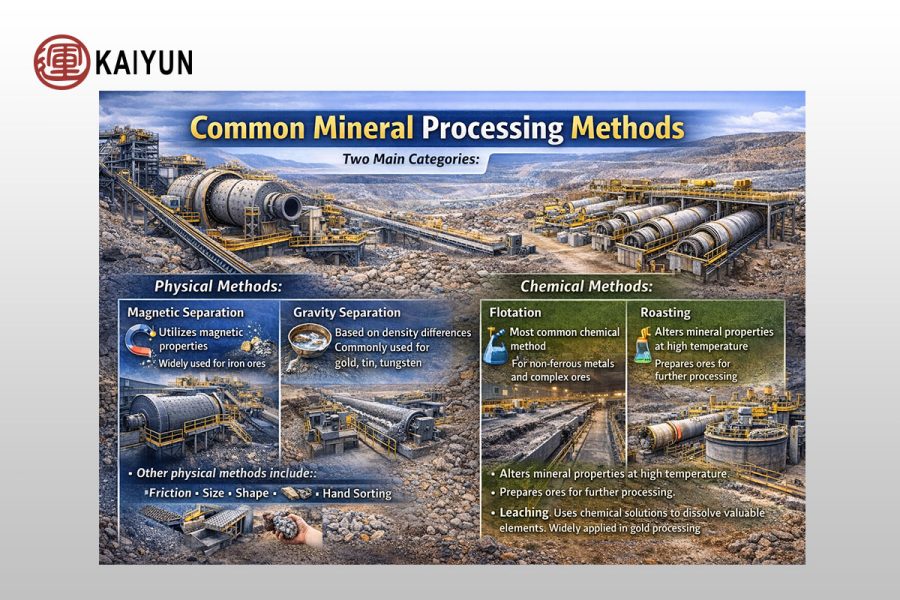

Based on different beneficiation principles, beneficiation methods are mainly divided into two categories: physical beneficiation and chemical beneficiation.

Physical Beneficiation Methods

Physical beneficiation utilizes differences in the physical properties of minerals for separation. Common methods include:

Magnetic Separation

Separates minerals based on differences in magnetic properties, widely used in iron ore and magnetic mineral beneficiation.

Gravity Separation

Separates minerals based on differences in density, commonly used in gold, tin, and tungsten ores.

Electrostatic Separation

Separates minerals based on differences in electrical conductivity, suitable for some rare metals and nonmetallic minerals.

Other Physical Beneficiation Methods

Including friction beneficiation, size separation, shape separation, and hand sorting,usually used as auxiliary or pre-selection processes.

Chemical Mineral Processing Methods

Chemical mineral processing separates and extracts minerals through chemical reactions or physicochemical processes. It mainly includes:

Flotation

One of the most commonly used chemical mineral processing methods, suitable for non-ferrous metals and complex ores.

Roasting

Altering the properties of minerals through high temperatures, creating conditions for subsequent beneficiation or smelting.

Leaching

Utilizing chemical solutions to dissolve and recover useful components; widely used in gold ore beneficiation.

What can we offer you?

Ore Beneficiation Process Analysis and Flow Design

Complete Solutions for Physical and Chemical Beneficiation

Equipment Configuration for Gold, Iron, and Polymetallic Ore Beneficiation

Project Planning, Installation, Commissioning, and Technical Support

Contact us for beneficiation solutions tailored to your ore conditions.