CIP (Carbon-in-Pulp) is one of the most efficient and widely used gold extraction technologies in modern mineral processing. Especially suitable for low-grade gold ores, the CIP method has become a core process in gold mining plants across Africa, Asia, and Latin America.

What is CIP in Gold Mining?

CIP (Carbon-in-Pulp) is a gold cyanidation process where gold is leached from ore and then adsorbed onto activated carbon suspended in the pulp. It differs from the CIL (Carbon-in-Leach) process mainly in that the leaching and carbon adsorption steps are done sequentially, rather than simultaneously.

This method is particularly effective for:

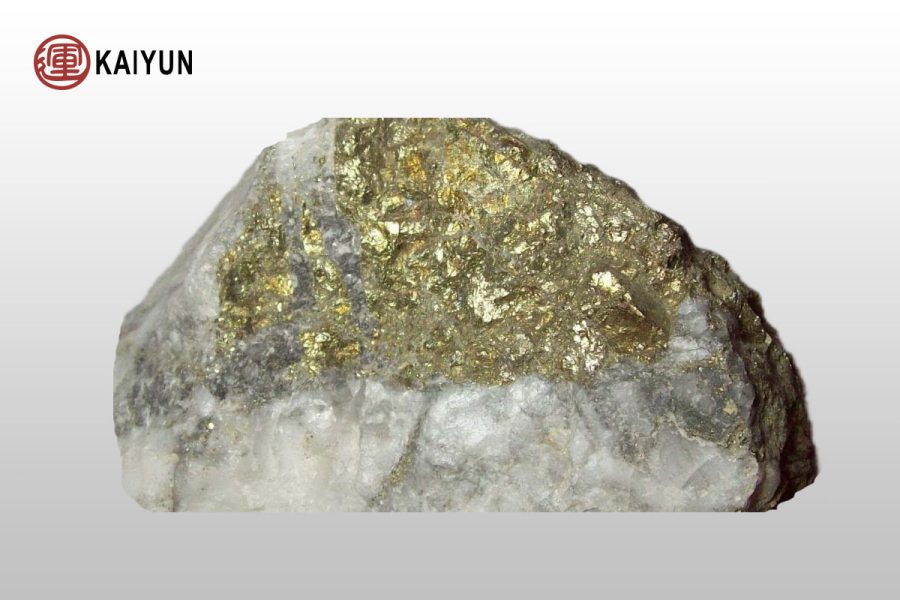

Low-grade gold ores

Oxidized gold deposits

Gold ores with fine particle size

CIP Process Flow

Crushing & Grinding

Gold-bearing ore is first crushed and ground into fine particles to expose gold minerals.

Thickening

The ground ore is mixed with water to form slurry, which is then thickened to increase pulp density.

Cyanide Leaching

The thickened slurry is pumped into a series of leaching tanks where cyanide is added to dissolve gold into the solution.

Carbon Adsorption

After leaching, activated carbon is introduced in a series of adsorption tanks. The dissolved gold ions are attracted to the carbon surface.

Gold Desorption

The gold-loaded carbon is separated and transferred to a desorption system, where gold is stripped from carbon using a hot caustic solution.

Electrowinning & Smelting

The gold-rich solution is passed through an electrowinning cell to recover gold as a solid, which is then melted into gold bars.

Benefits of CIP Gold Processing

High Recovery Rate – Up to 95–98% gold recovery from ore.

Proven and Stable Technology – Used in thousands of mining projects globally.

Low Operating Cost – Less carbon loss and reagent consumption compared to other methods.

Modular Design Available – Easy to install and expand.

Environmental Control – Tailings treatment and water recycling systems can be integrated.

Choosing the Right CIP Plant for Your Mine

When selecting a gold CIP plant, consider:

Ore type and grade

Daily processing capacity (e.g. 100–1000 TPD)

Heating method for desorption (electric/steam)

Automation level

Environmental regulations in your region

After-sales support and installation service

A custom CIP solution can significantly improve your ROI and gold recovery rate.

Need Help Designing Your Gold CIP Plant?

As a professional gold processing equipment manufacturer, we offer:

Ore testing and process design

Customized equipment manufacturing

On-site installation and training

Turnkey project delivery

👉 Contact us today to get a tailored flowchart and quotation based on your gold ore sample.