Project Background

The zinc oxide rotary kiln project is to improve the efficiency and product quality of zinc oxide production and solve the problems of high energy consumption and unstable production in traditional production processes. Zinc oxide, as an important chemical raw material, is widely used in rubber, coatings, plastics and other fields. Therefore, the optimization of its production process is of great significance to improving the competitiveness of the industry.

This project selected the rotary kiln as the core equipment, aiming to improve the production process of zinc oxide through advanced kiln technology and achieve the goals of energy saving, environmental protection and efficient production.

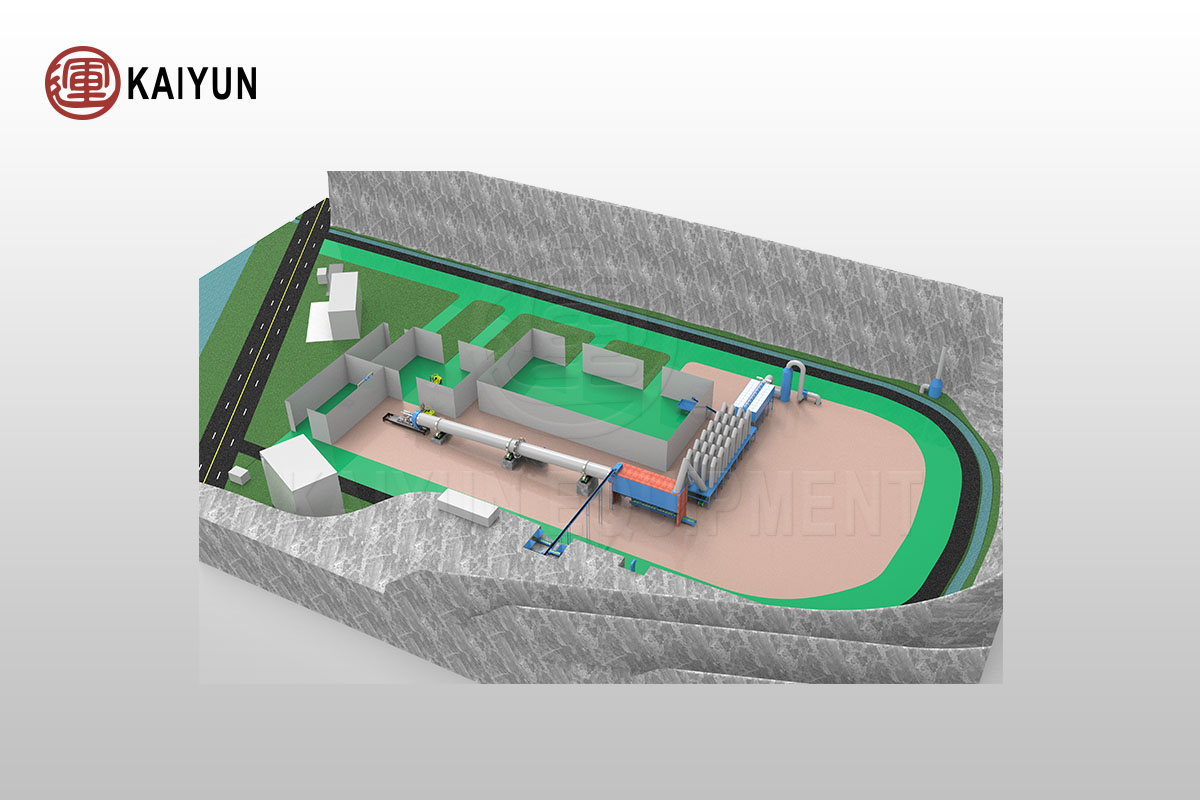

Project Implementation Plan

Preliminary Investigation and Feasibility Analysis

Before the project started, the technical team conducted a full investigation and analysis of the existing zinc oxide production process, studied the application of rotary kilns at home and abroad, and determined the specific design of the rotary kiln based on the current status of the enterprise. After multiple demonstrations, a zinc oxide rotary kiln solution suitable for local resources and needs was selected.

Equipment Selection and Design

The most advanced rotary kiln technology on the market is adopted, including multi-stage heating, temperature control precision control system, and efficient dust removal and desulfurization equipment. The kiln body is made of highly wear-resistant steel, and the temperature distribution in the furnace is optimized to ensure the maximum thermal efficiency of the whole process.

Construction and installation

During the construction of the project, professional technicians installed the equipment according to the design drawings and debugged various equipment. In order to ensure the efficient operation of the rotary kiln, the construction team adopted advanced technical means during the installation process, such as automatic control system and remote monitoring system, so as to monitor the key parameters such as temperature and gas composition in the kiln in real time and adjust the production process in time.

Trial production and optimization

After the installation of the rotary kiln equipment, several rounds of trial production were carried out. During this stage, the technical team continuously debugged the operating parameters of the rotary kiln, such as temperature, air flow velocity, fuel ratio, etc., to ensure the stable operation of the equipment during the production process and achieve the expected product quality and production efficiency.

Formal production

After a period of debugging and optimization, the zinc oxide rotary kiln project entered the formal production stage. During the production process, the system automation monitoring system can feedback various parameters in real time to ensure that the equipment operates in the best state. In addition, in order to ensure the stability of product quality, the production process is strictly controlled to ensure that the zinc oxide produced in the end meets the standards of high purity and high consistency.

Project Results

Production efficiency improvement

Through the application of rotary kiln technology, the project successfully shortened the production cycle of zinc oxide by 20% and significantly improved production efficiency. The kiln temperature control is precise, the thermal energy utilization rate is greatly improved, and a large amount of fuel costs are saved.

Product quality improvement

The investment of new equipment has significantly improved the quality of zinc oxide products, especially in terms of purity and particle uniformity, reaching the advanced level at home and abroad. The improvement of product quality has significantly improved customer satisfaction with the product.

Energy saving and emission reduction effect

By optimizing the thermal energy utilization efficiency of the rotary kiln, the project has achieved a 30% reduction in energy consumption. Exhaust gas emissions have been effectively treated through advanced dust removal systems and desulfurization devices. The environmental protection indicators of the project have reached national standards, reducing the impact on the environment during the production process.

Cost control

The energy consumption of the entire project has been greatly reduced, and due to the efficient operation of the rotary kiln, the maintenance cost of the production line has also been effectively controlled. Overall, the comprehensive cost of the project is about 15% lower than that of the traditional production line.

Conclusion

Through the implementation of this project, the company has not only improved the efficiency and product quality of zinc oxide production, but also achieved remarkable results in reducing energy consumption and emissions. The successful application of rotary kiln has made positive contributions to the technological progress and green development of zinc oxide industry. With the further optimization and development of the project, the company will continue to promote intelligent and green production mode and set a new benchmark for the industry.