KC Series Jaw Crusher

Durable and efficient KC jaw crusher for stone, ore, and aggregate crushing. Suitable for mining, quarrying, and construction sites.

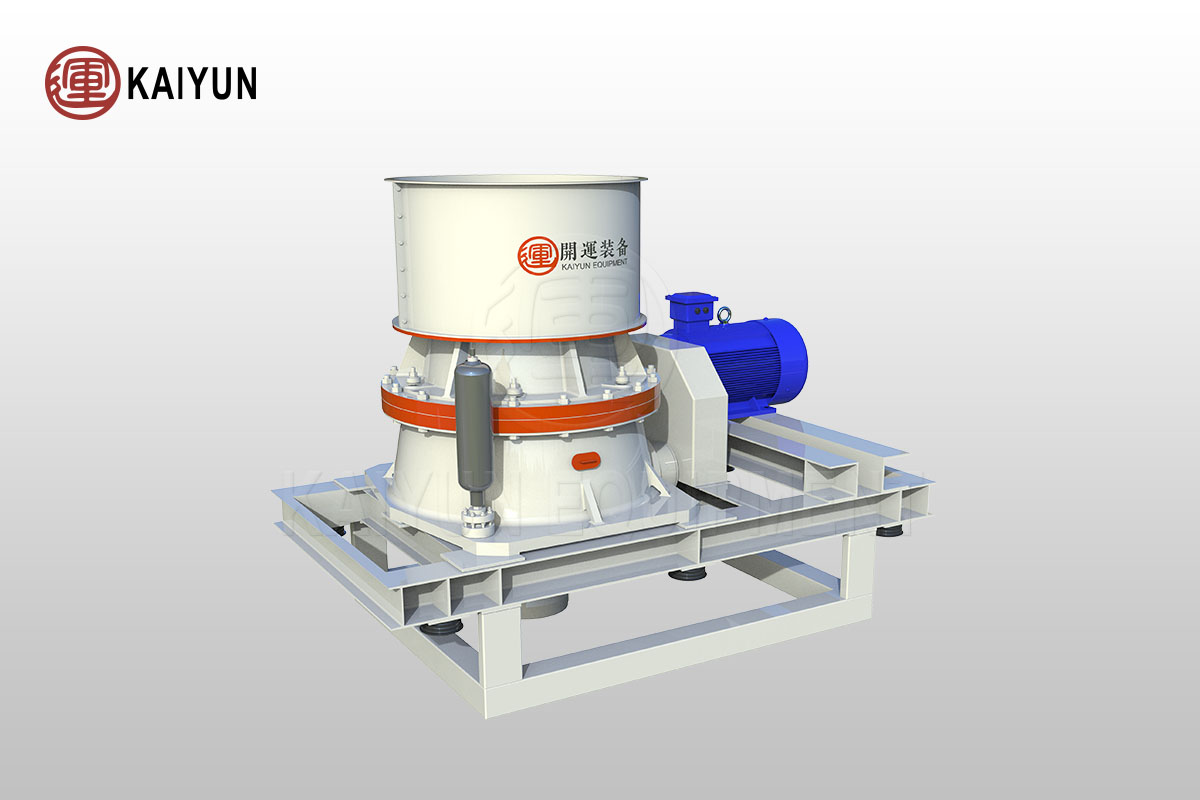

HPT Series Multi-Cylinder Hydraulic Cone Crusher

High-performance hpt series multi-cylinder hydraulic cone crusher for granite, basalt, iron ore, and hard rock. Ideal for mining, aggregates, and construction applications.

CTB Permanent Magnetic Drum Separator

CTB Permanent Magnetic Drum Separator is suitable for various stages, including pre-selection, rough selection, and fine selection. With a wide range of feed particle sizes, it can handle materials from 2 to 10mm.

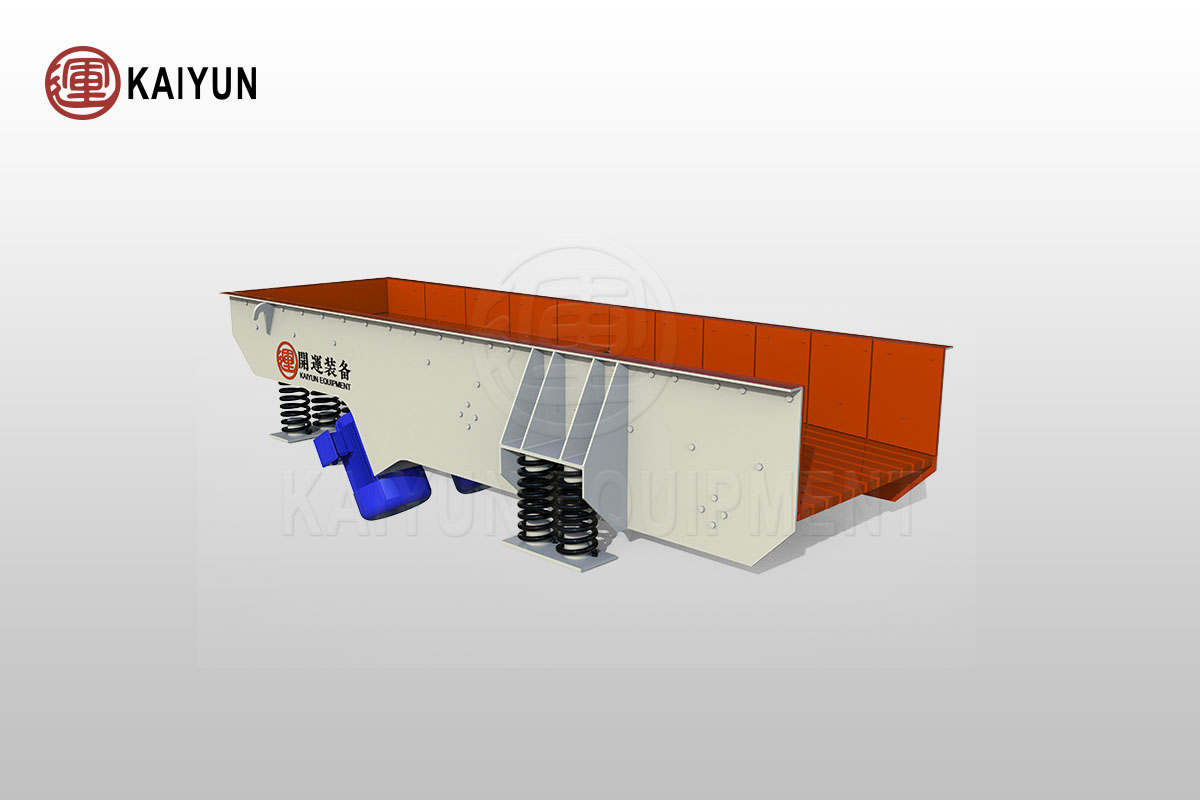

ZSW Vibrating Feeder

ZSW vibrating feeder is specifically engineered to meet the needs of industries such as metallurgy, coal mining, beneficiation, building materials, chemicals, and abrasives.

GZT Vibrating Feeder

GZT Vibrating Feeder is specifically designed for light-duty conditions. stands out as an ideal feeding solution for mobile stations, semi-fixed stations, and small material yards.

Chute Feeder

The chute feeder is widely used in industries such as mining, beneficiation, chemical processing, cement, and building materials. It plays a crucial role in the uniform and continuous feeding of materials from storage bins to crushing and transportation machinery.

KS/H Series Single-Cylinder Hydraulic Cone Crusher

KS/H series single-cylinder hydraulic cone crusher, a cornerstone in the modern mining and stone industries, is divided into the KS and KH series. These crushers seamlessly integrate advanced technologies in mechanics, hydraulics, electronics, and intelligent control, and are specifically designed for heavy-duty conditions.

Metallurgical Rotary Kiln

The metallurgical rotary kiln is leverages its high-temperature roasting capabilities to facilitate the physical and chemical transformation of metal ores. This accelerates the metal refining and material preparation processes.

Wet Rotary Kiln

The wet process rotary kiln adopts a unique tilting design and advanced sealing technology to ensure uniform material handling and stable product quality during the calcination process.

Dry Process Rotary Kiln

Dry process rotary kiln is an indispensable core equipment in cement production, metallurgy, chemical industry, environmental protection and other industries.

Belt Conveyor

Belt conveyor plays a vital role in connecting various production equipment and ensuring the continuity and automation of the production process.

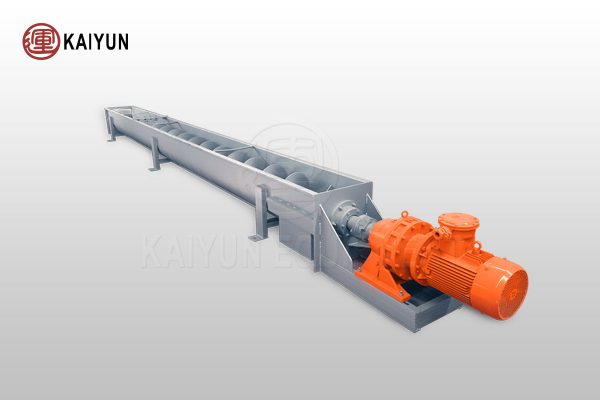

Screw Conveyor

The screw conveyor is widely used for the conveyance of powdery, granular, and small-sized materials such as ore powder, coal powder, soda ash, recycled rubber powder, zinc oxide, calcium carbonate, and small lumps of coal.