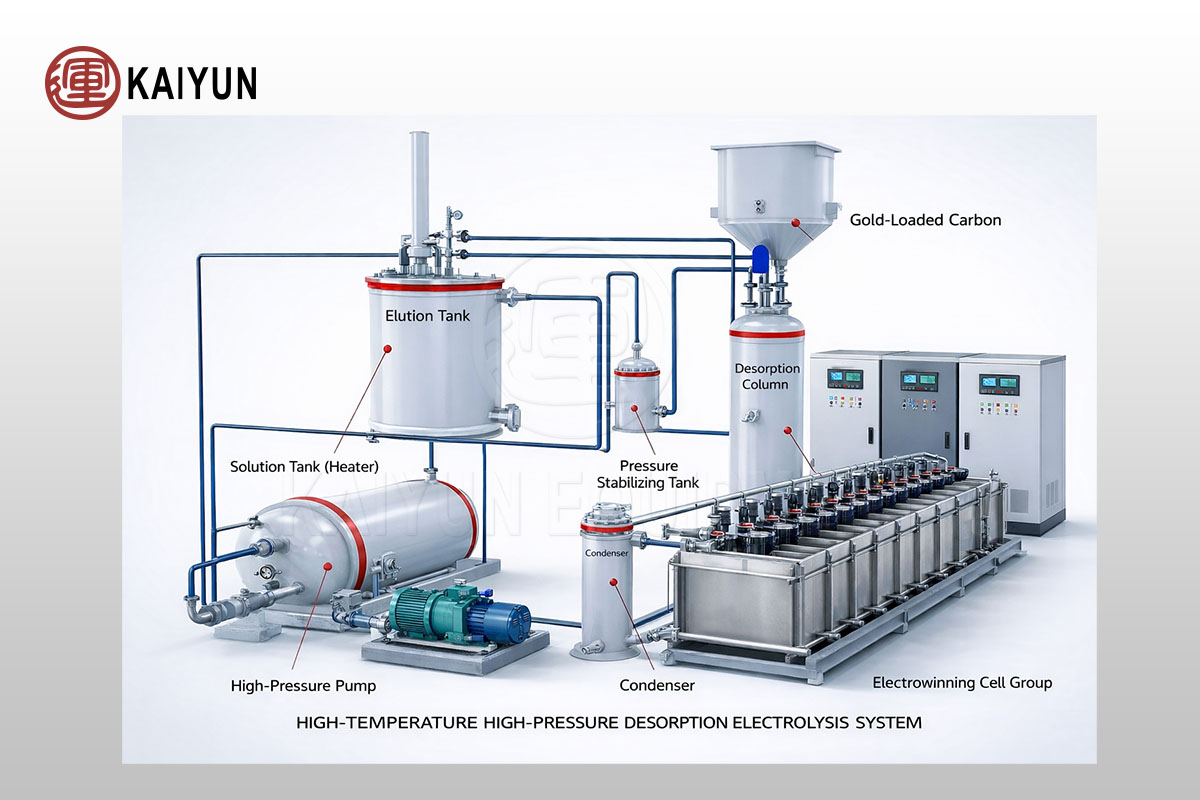

High Temperature High Pressure Desorption Electrolysis System for Gold CIP/CIL Plant

High temperature high pressure desorption electrolysis system for gold CIP/CIL processing plant. Efficient gold desorption and electrowinning solution with high recovery rate, stable operation and automated control.

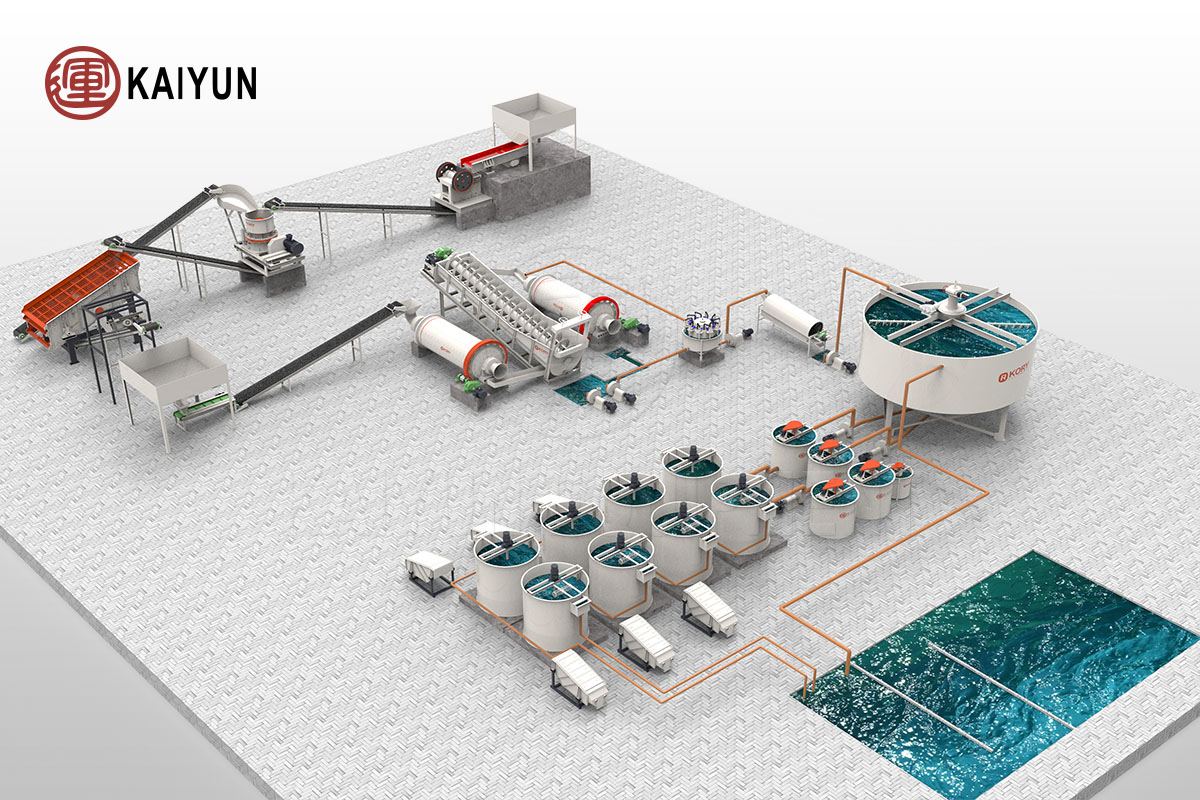

Gold Ore CIP Processing Line: Core Equipment Overview

Complete Gold Ore CIP (Carbon-in-Pulp) Processing Line covering crushing, grinding, leaching, carbon adsorption, desorption-electrolysis, and water recycling. High gold recovery rate, stable operation, lower costs, and eco-friendly design. Ideal solution for modern gold mining projects.

Core Requirements for Activated Carbon in Gold CIP Processing

Learn the core requirements for activated carbon in Gold CIP processing. Improve CIP adsorption efficiency, gold recovery, and plant stability with the right carbon selection.

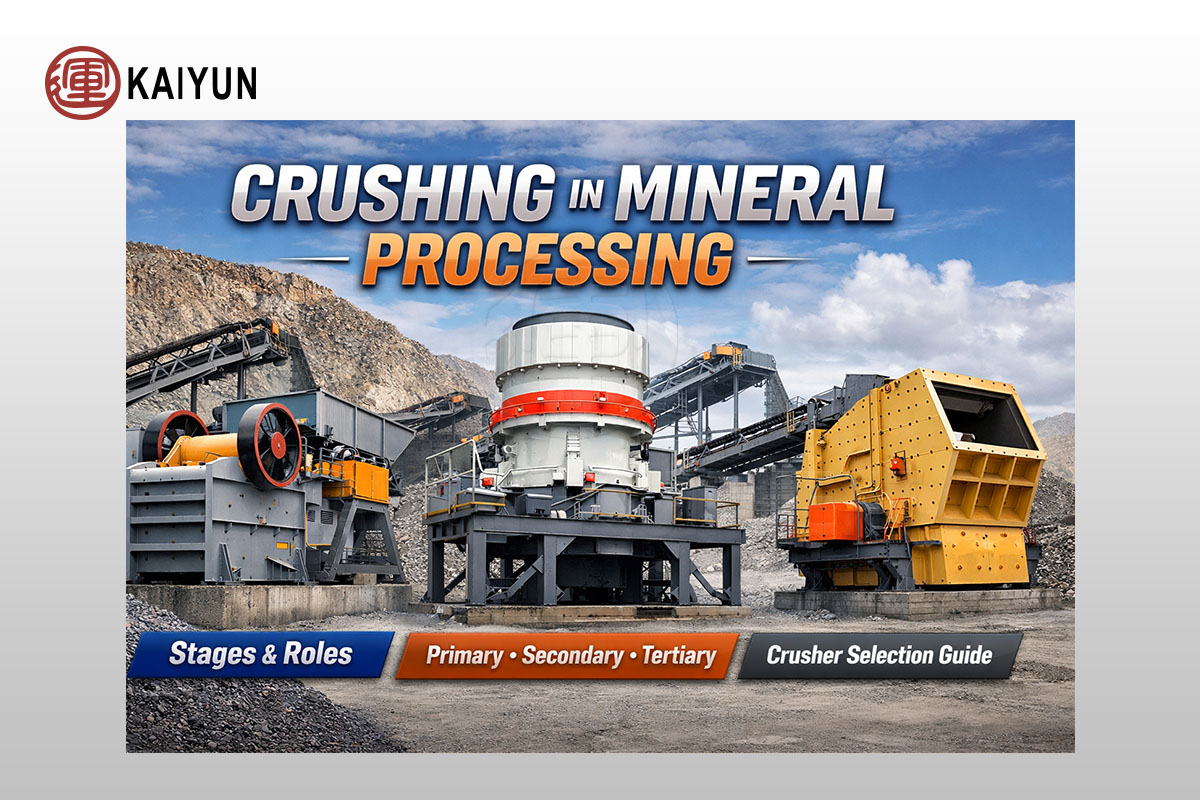

Crushing in Mineral Processing: Roles, Stages, and Crusher Selection Guide

Learn the role of crushing in mineral processing, three crushing stages, and how to select the right crusher for different ores and capacities.

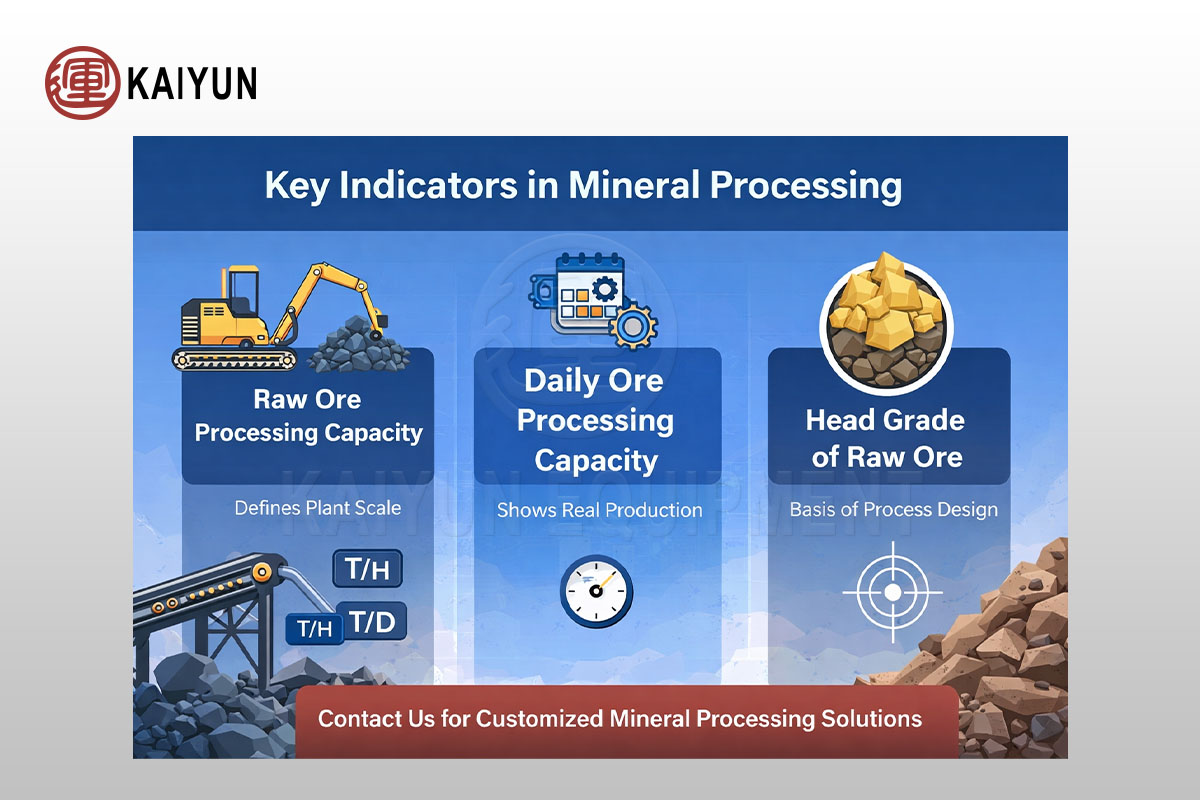

Raw Ore Processing Capacity & Head Grade | Mineral Processing Plant Design

Learn how raw ore processing capacity, daily throughput and head grade affect mineral processing plant design, equipment selection and production efficiency.

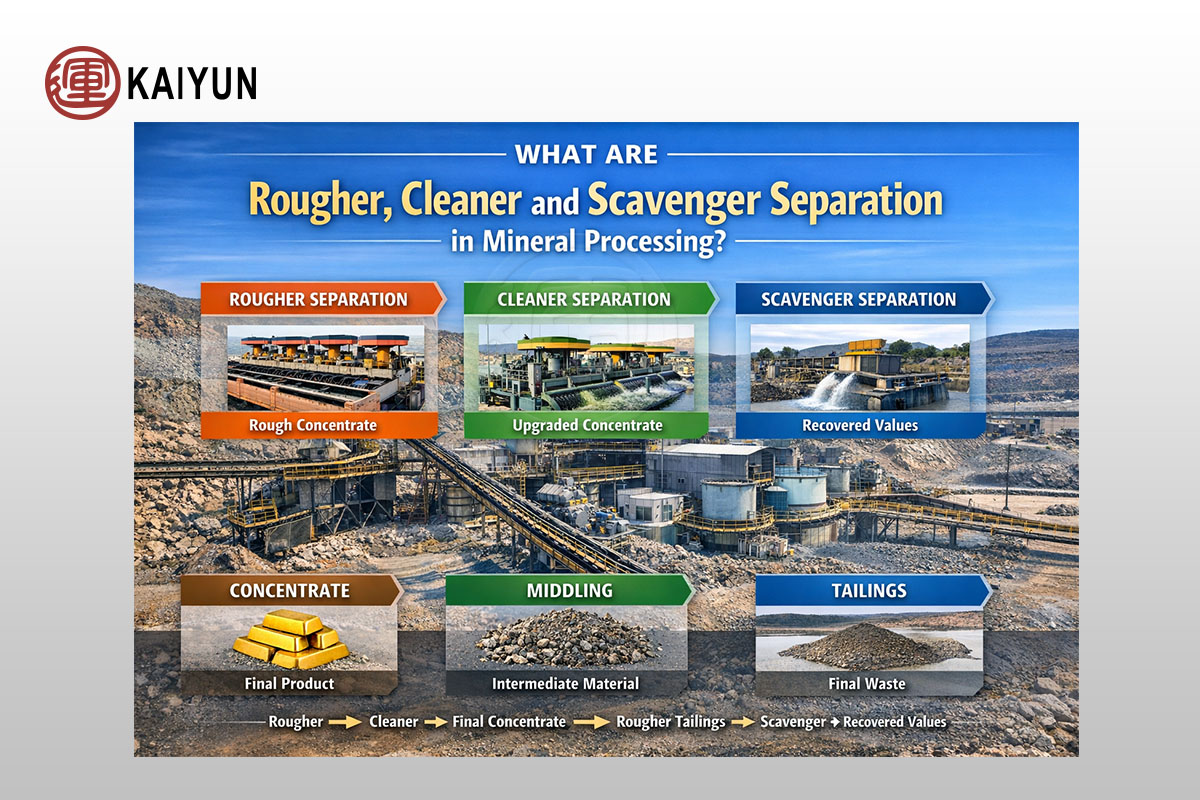

What Are Rougher, Cleaner and Scavenger Separation in Mineral Processing?

Learn the differences between rougher, cleaner and scavenger separation in mineral processing, and understand concentrate, middling and tailings in a clear flowsheet overview.

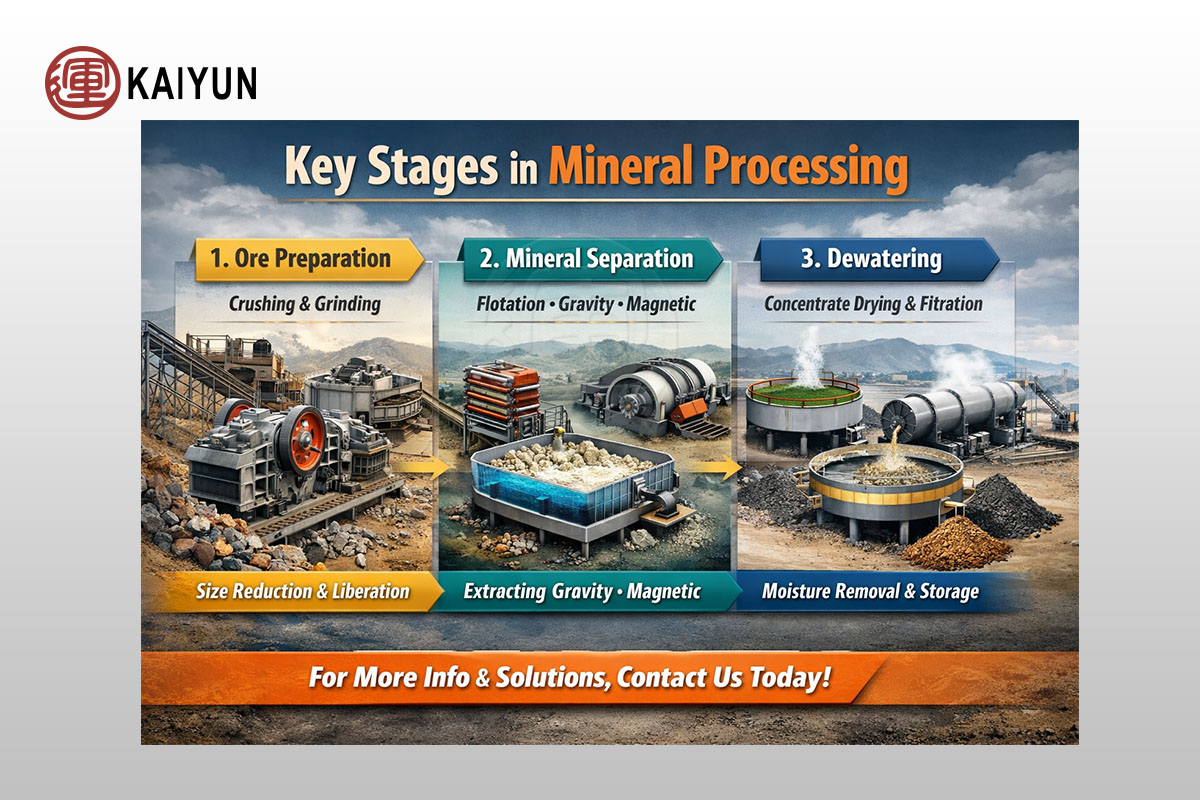

What are the basic operations typically involved in a mineral processing process?

Mineral processing involves ore preparation, separation, and dewatering—liberating minerals, separating valuables, and removing moisture for use and sale.

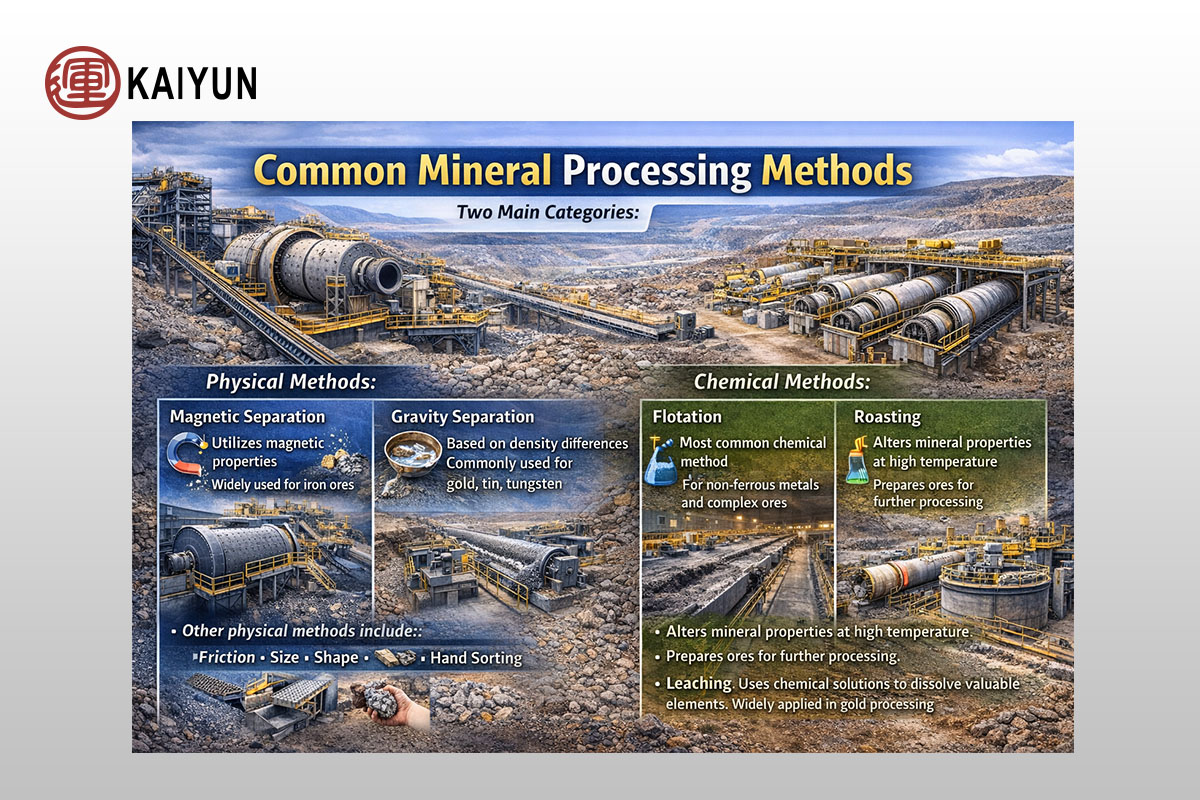

What are the Commonly Used Beneficiation Methods?

Beneficiation methods include physical separation by density, magnetism, or conductivity, and chemical processes such as flotation, roasting, and leaching.

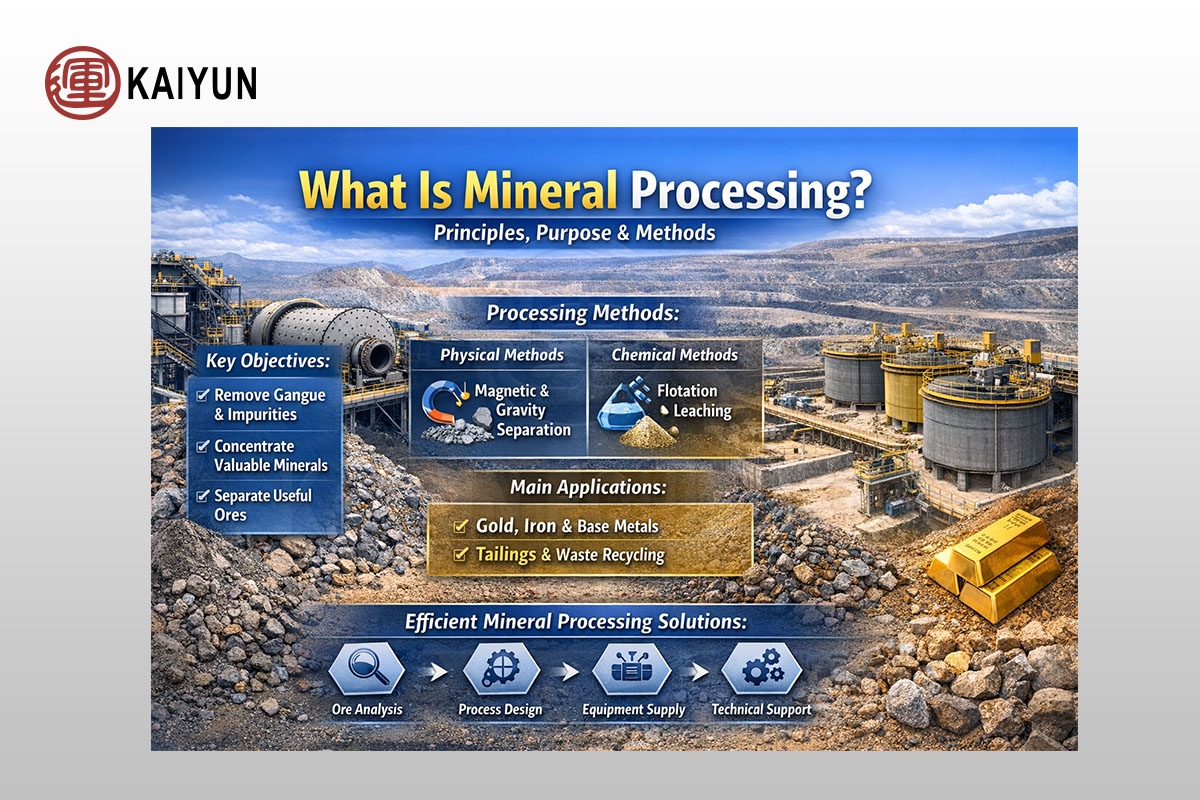

What is Mineral Processing?

Mineral processing is an indispensable and crucial step in mining production. Through scientific mineral processing techniques, valuable minerals in ore are efficiently separated and enriched to provide qualified concentrate products for subsequent smelting and industrial applications.

- 1

- 2

- 3

- …

- 9

- Next Page »