When it comes to modern gold extraction, two of the most widely used methods are Carbon-in-Leach (CIL) and Carbon-in-Pulp (CIP). While they share similarities, there are key differences that can influence efficiency, cost, and plant design. Understanding these processes can help mining operations choose the right solution for their needs.

What is CIP (Carbon-in-Pulp)?

The CIP process involves leaching gold from ore using a cyanide solution. After leaching, activated carbon is introduced to the slurry to adsorb dissolved gold. In this method, the carbon and the pulp are processed separately, which allows for a more controlled adsorption stage.

Key points of CIP

Adsorption occurs after leaching.

Requires multiple adsorption tanks in series.

Well-suited for ores with longer leaching times.

More traditional, widely adopted process.

What is CIL (Carbon-in-Leach)?

The CIL process combines leaching and adsorption into a single step. In CIL, activated carbon is added directly into the leach tanks, allowing gold adsorption to occur simultaneously with leaching.

Key points of CIL

Leaching and adsorption occur together.

Requires fewer tanks compared to CIP.

Often faster and more cost-efficient.

Better suited for ores that are easy to leach.

Main Differences Between CIP and CIL

| Aspect | CIP (Carbon-in-Pulp) | CIL (Carbon-in-Leach) |

| Process Sequence | Leaching first, then adsorption | Leaching and adsorption combined |

| Number of Tanks | Typically more | Fewer required |

| Capital Cost | Higher | Lower |

| Processing Speed | Slower | Faster |

| Best Suited For | Complex ores, longer leach times | Freely leachable ores |

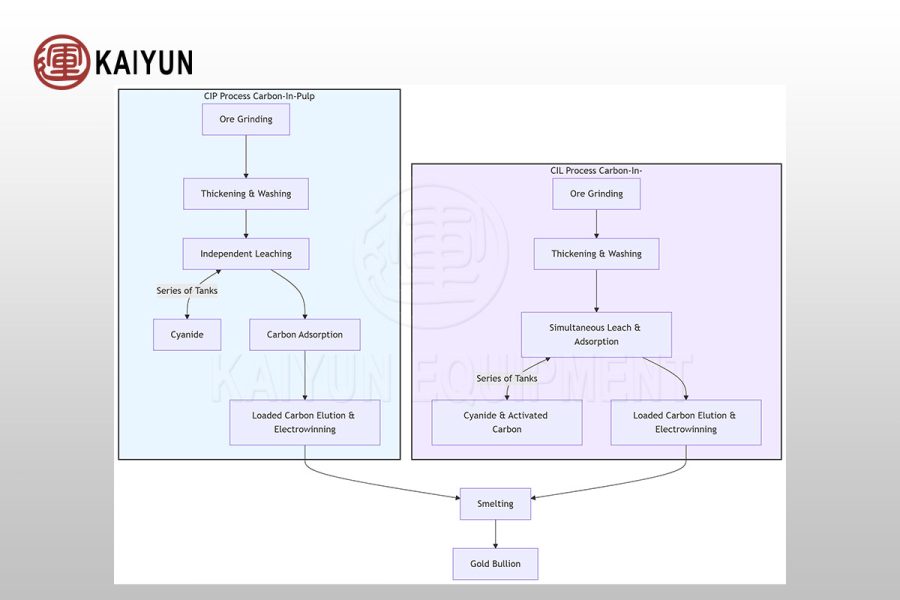

Gold CIP vs CIL Process Flow Comparison Diagram

Choosing the Right Process?

CIP is often preferred for ores requiring extended leaching or where adsorption control is critical.

CIL is ideal for projects where minimizing capital costs and accelerating processing are priorities.

At the end of the day, both methods have proven track records in gold mining operations worldwide. Selecting between CIL and CIP depends on ore characteristics, plant design, and operational goals.

Looking for reliable gold processing equipment tailored to your project? Our team provides professional solutions for both CIP and CIL plants, ensuring efficient gold recovery and lower operational costs.