Recently, affected by the expectation of new tariff policies, market concerns about inflation and trade frictions have intensified. As a traditional safe-haven asset, gold has once again become the focus of capital pursuit, and its price has continuously refreshed historical highs. The continued rise in gold prices has driven the exploration and mining boom of gold mines around the world, especially in Africa, South America and parts of Asia. At the same time, the effective beneficiation and recovery technology of gold ore has become a key link for gold mining companies to improve their economic benefits. This article will give you an in-depth analysis of the types of gold ore and the current mainstream gold beneficiation technology and methods.

Main types of gold ore

Gold ore can be divided into the following categories according to its geological origin, mineral composition and occurrence state:

1. Quartz vein type gold ore

Gold is mainly found in quartz veins in the form of natural gold, often coexisting with pyrite. The particle size distribution of gold is wide, ranging from microscopic gold to coarse gold. This type of ore is generally of high grade and is the focus of current gold resource development.

2. Broken zone altered rock type gold ore

Gold is found in altered rocks affected by fractures and hydrothermal action. The ore structure is complex and is often accompanied by sulfides such as pyrite and chalcopyrite. Gold is closely combined with gangue minerals and is mostly embedded in fine particles, making beneficiation relatively difficult.

3. Volcanic rock type gold ore

Produced in volcanic rocks and subvolcanic rocks, it contains a variety of metal minerals, such as sphalerite and galena. The types of surrounding rock alteration are rich, the ore grade is uneven, and it often contains complex mineral components that interfere with beneficiation.

4. Placer gold ore

It is a secondary deposit formed by weathering, transportation and sedimentation. Gold mainly exists in loose gravel such as rivers and beaches as coarse grains or flaky natural gold. Recovery is relatively easy, but the resource distribution is scattered and the grade is unstable.

Common beneficiation methods for gold ore-gravity separation.

Gravity separation: green and environmentally friendly, low cost

Gravity separation uses the density difference between gold and gangue minerals for separation. It is mainly used for the recovery of coarse or medium gold, especially suitable for placer gold and some quartz vein gold mines with high natural gold content.

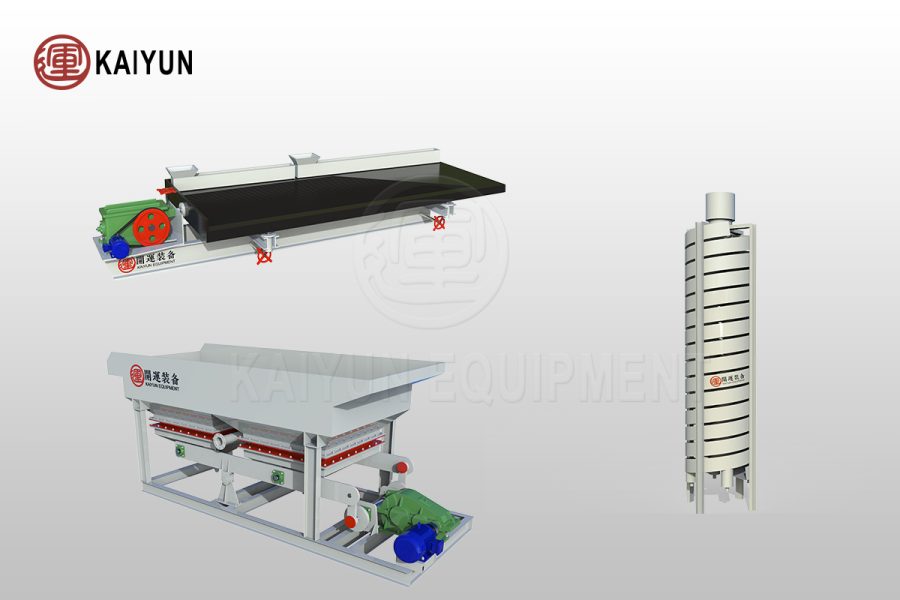

1. Shaking table gravity separation

The shaking table separates gold and other minerals according to density through the combined action of inclined water flow and vibration. After the slurry enters the shaking table, gold tends to concentrate at the bottom of the bed due to its high density and fast sedimentation; light minerals are discharged with the water flow.

Applicable particle size: 0.03~0.5mm

Features: Suitable for fine gold selection and associated metal pre-separation.

2. Jigging gravity separation

The minerals are separated by density through periodic pulsating water flow, and heavy minerals sink to the bottom and enrich. The jig has a significant effect on medium and coarse gold, especially suitable for the recovery of medium and coarse gold in placer gold and vein gold mines.

Applicable particle size: 0.5~20mm

Advantages: low energy consumption, large processing capacity, simple equipment, and convenient maintenance.

3. Chute gravity separation

With the combined effect of gravity and slow water flow, gold is deposited at the bottom of the trough and gradually collected. It is suitable for the recovery of coarse gold in natural sedimentary environments such as river gold.

Advantages: small investment, simple operation, suitable for field or mobile operation scenarios.

4. Centrifugal gravity separation

The centrifugal force generated by high-speed rotation makes the gold particles settle quickly, with high separation efficiency, suitable for the recovery of fine gold particles.

Applicable particle size: <0.03mm

Typical equipment: Knelson centrifugal concentrator, STLB series centrifuge, etc.

Advantages: high recovery rate, especially suitable for pre-selection of muddy complex ores.

There are various methods for the beneficiation of gold ores, and different types of ores need to be equipped with targeted process flows. Whether it is traditional gravity separation, flotation, cyanidation, or emerging biological gold extraction and non-cyanidation technology, it is necessary to conduct sufficient beneficiation tests and process design based on the actual ore properties.

Henan Kaiyun Intelligent Equipment Co., Ltd. has been engaged in the field of gold beneficiation for many years and has rich on-site experience and technical reserves. We can tailor the optimal gold extraction solution according to the characteristics of the customer’s ore to help achieve the goal of efficient, green and high-recovery gold extraction.