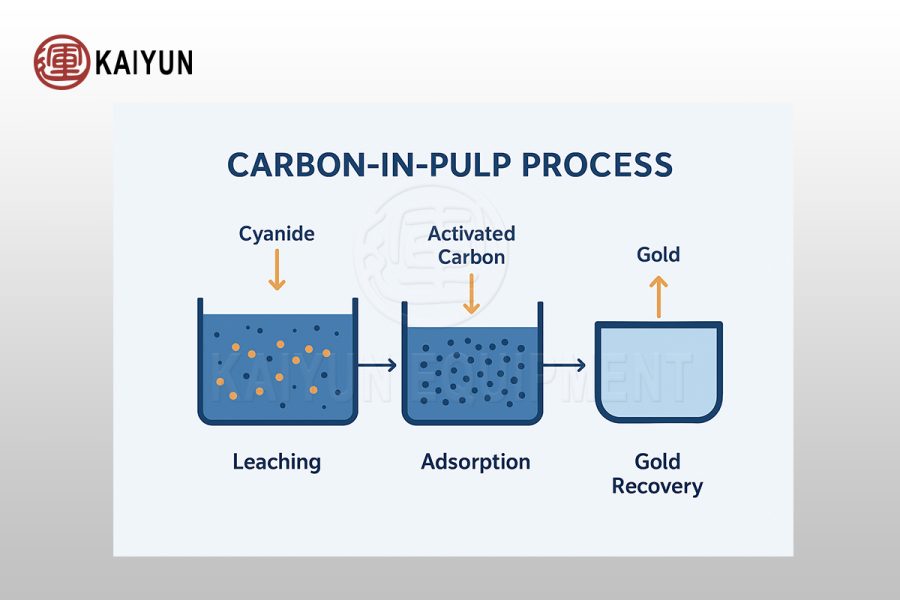

The cyanidation and adsorption of gold is a continuous process, not separate steps. To help operators better understand the full CIP process, we break down each stage and highlight the critical details for stable production and reduced losses.

I. Process Overview

Leaching Tanks – The first few tanks are pure leaching tanks, where gold dissolves into solution.

Adsorption Tanks – In the last few tanks, activated carbon is added to adsorb gold and other metals.

Tailings Discharge – The slurry flowing out from the last tank is tailings.

Solid tailings gold grade ≤ 0.3 g/t → Qualified for discharge

Liquid gold grade ≤ 0.02 g/m³ → Qualified for discharge

II. Activated Carbon Usage & Management

1. Carbon Selection

Recommended: 8–16 mesh activated carbon from reputable manufacturers.

Different carbons vary: high adsorption capacity → less wear resistant; strong wear resistance → lower adsorption capacity.

Operators should observe slurry surface foam and tailings conditions to evaluate performance.

2. Carbon Pretreatment

Before use, activated carbon must be washed and ground:

Stir in a washing tank for several hours → remove black foam and fragile carbon.

Repeat until no black foam remains on water surface.

Purpose: remove weak carbon particles that would otherwise adsorb gold/silver inefficiently.

3. Number of Adsorption Tanks

Normally 4–5 adsorption tanks are sufficient.

More tanks = more carbon consumption and wear.

Final number should be determined by lab assays, pulp flow rate, and leaching time.

4. Carbon Dosage

Literature: 10–15 g/L slurry, but actual production often requires more.

Principle: add as little as possible while ensuring efficiency to reduce loss.

Example (200 t/d, Au grade 2.36 g/t):

500 kg carbon in 1st tank → ~5.4 g Au/kg carbon after 6 days

1000 kg carbon in 1st tank → ~5.2 g Au/kg carbon after 11 days

Conclusion: excessive carbon addition does not always improve economics.

5. Distribution Rule

Follow increasing dosage principle – less carbon in front, more in later tanks:

Tank 1: ~500 kg

Tank 2: ~800 kg

Tank 3: ~1500 kg

Tank 4: ~2000 kg

Tank 5: ~2500–3000 kg

For plants ≤300 t/d, this dosage range generally ensures high adsorption efficiency.

III. Carbon Transfer & Extraction

Carbon Transfer (Air Lifter Method):

Operated by opening the air valve to lift carbon between tanks.

Sequential Operation:

First tank carbon is removed, washed, and sent for elution/electrowinning.

Carbon from Tank 2 is transferred into Tank 1, Tank 3 into Tank 2, and so on.

Fresh or regenerated carbon is added into the last tank.

Benefits:

Stable loaded carbon grade

Avoids dilution of carbon gold content

Reduces wear and gold loss

IV. Core Principles

Fewer tanks, optimized carbon use → reduce unnecessary losses.

Pretreat carbon before use → ensure adsorption efficiency.

Add carbon progressively (front low, back high) → dynamic adjustment by assay results.

Follow strict transfer sequence → maintain stable carbon grade.

Choose high-quality carbon → ensures wear resistance and reliable performance.