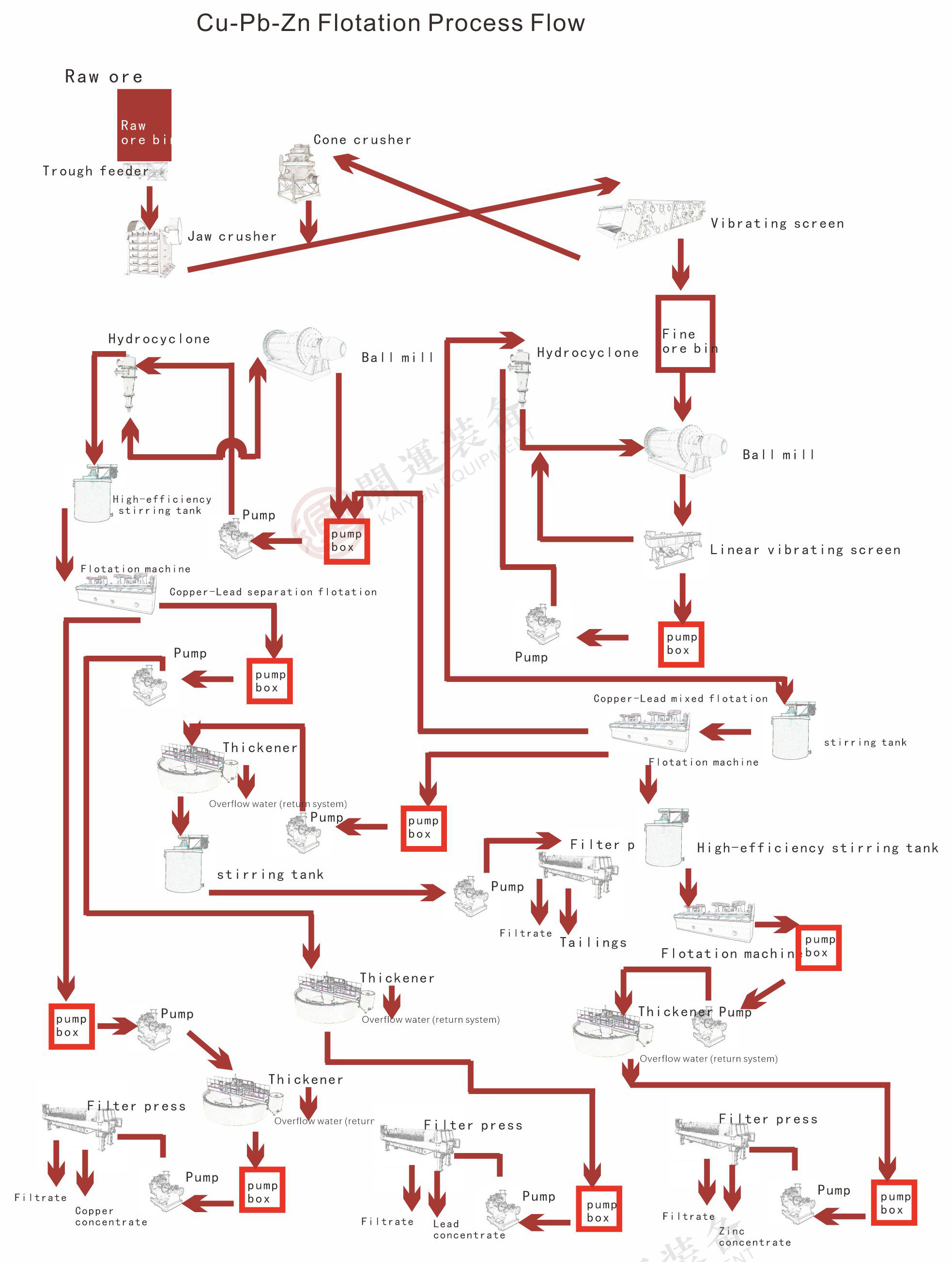

Process introduction

The Cu-Pb-Zn Ore Beneficiation Process adopts a mixed flotation-concentrate regrinding process, which aims to reduce the grinding cost, is easy to manage, and uses new non-toxic flotation reagents to achieve an efficient and environmentally friendly beneficiation process.

Application field

The mixed flotation-concentrate regrinding process is suitable for Cu-Pb-Zn sulfide ores with close symbiotic relationships, difficult to dissociate, and unevenly embedded particle sizes.

Table of Contents

Process details

1. Novel beneficiation process and lower operating cost

– The copper-lead mixed concentrate regrinding process is adopted, and all the raw ores do not need to be finely ground, saving grinding costs.

– Concentrate regrinding further dissociates the copper-lead concentrate monomers and has a good de-drug effect, creating favorable conditions for the separation of copper and lead.

2. Strengthen the flotation process and improve the grade of copper concentrate

– Strictly implement the reagent system in the roughing section, control the amount of reagents, achieve the goal of “early collection as early as possible”, and reduce multiple cycles and unnecessary losses.

– Make full use of the secondary enrichment effect of the foam, and wash the concentrate foam by adding water appropriately to reduce the impurities in the foam and achieve the purpose of enhanced flotation.

3. Copper-lead mixed flotation separation

– The copper-lead mixed concentrate is separated first in the flotation stage, and the lead concentrate and copper concentrate are separated by flotation after regrinding. The two concentrates are dehydrated separately.

4. Zinc flotation separation

– The tailings of the copper-lead mixed flotation are stirred and slurried before zinc concentrate flotation. The obtained concentrate product is dehydrated to become a zinc concentrate product.

Process flow chart