Introduction

Depending on the different properties of feldspar ore, there are different process options, including magnetic separation, flotation or combined beneficiation process, etc., so as to remove impurities such as iron, quartz, mica, etc., and obtain feldspar concentrate containing potassium and sodium, aiming to obtain high-grade feldspar concentrate.

Application Field

The feldspar beneficiation process is suitable for potassium feldspar, sodium feldspar and nepheline syenite, etc.

Table of Contents

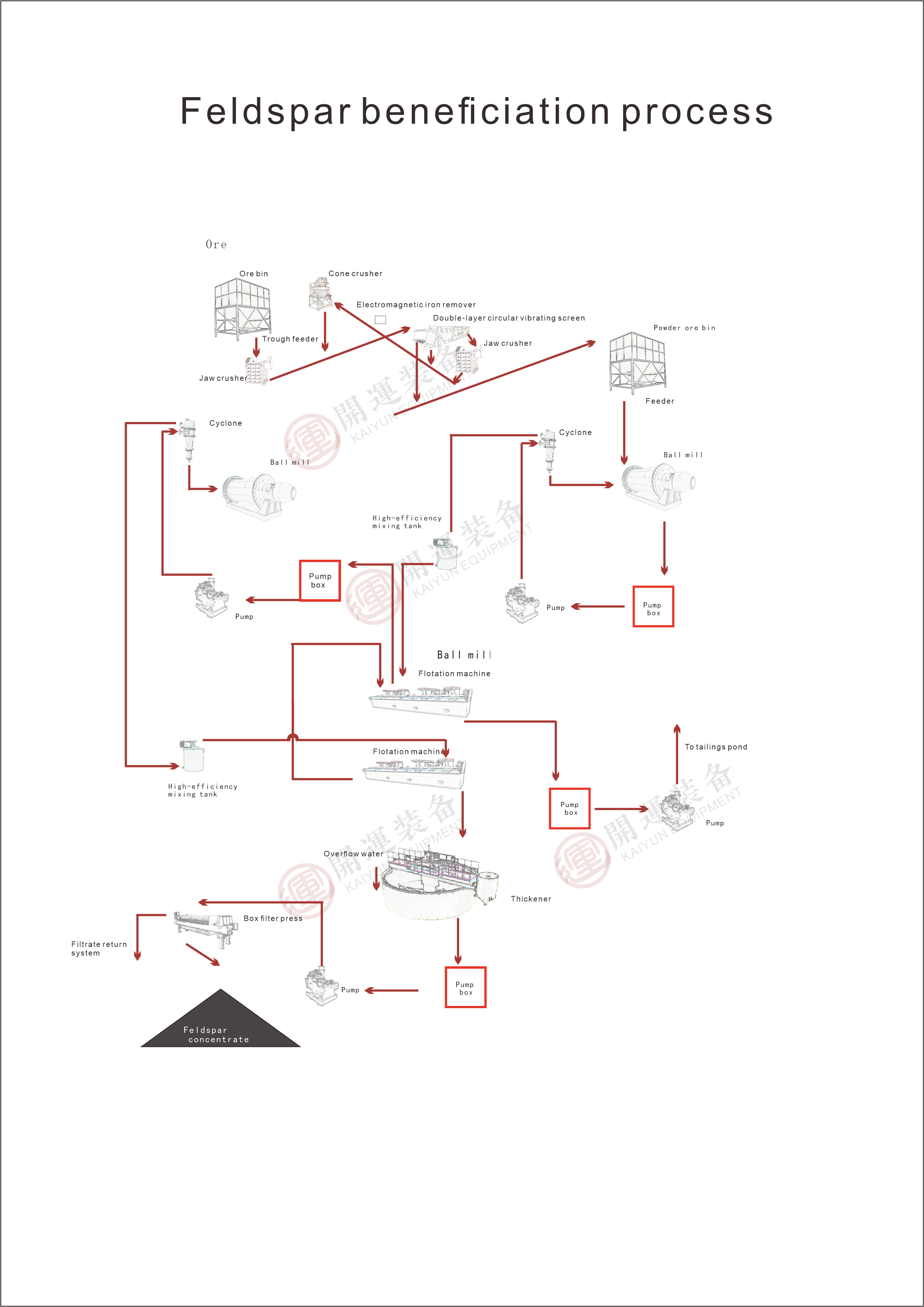

Process Flow

Crushing and screening stage

Depending on the different bulk particle sizes of the original ore, there are different crushing process designs, from a simple one-stage crushing process to a three-stage crushing process, the block ore is coarsely crushed, and then screened. The qualified ore in the crushing stage enters the grinding operation, and the ore on the screen is returned to the fine crushing, ensuring the qualification of the ore particle size entering the next stage.

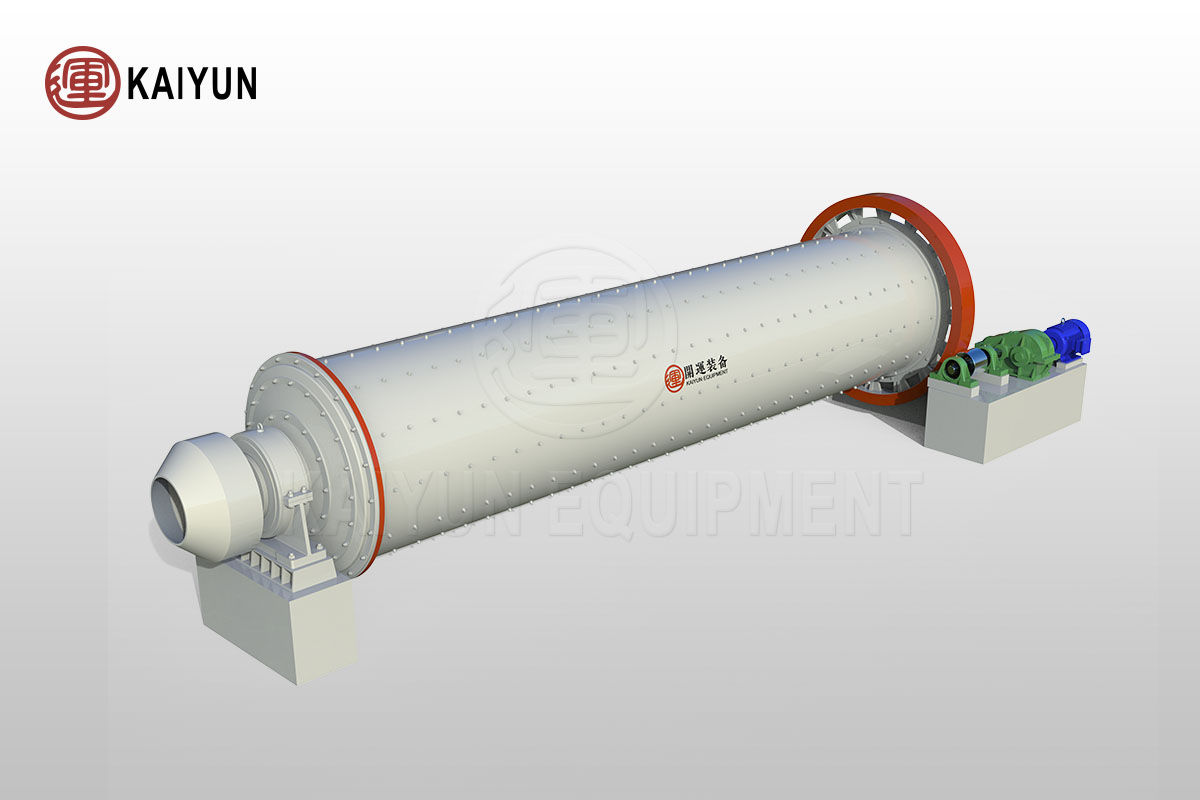

Grinding and classification stage

The qualified products in the crushing stage enter the wet grid ball mill for grinding, the discharge of the ball mill enters the classification equipment for classification, the sedimentation of the classification equipment returns to the ball mill for re-grinding, and the overflow of the classification equipment is the qualified product in the grinding stage.

Desliming stage

The qualified ground material is sent to the desliming bucket for desliming.

Separation stage

Magnetic separation stage

After desliming, the ore enters the two-stage magnetic separation of weak magnetic and strong magnetic to remove the magnetic substances in the ore.

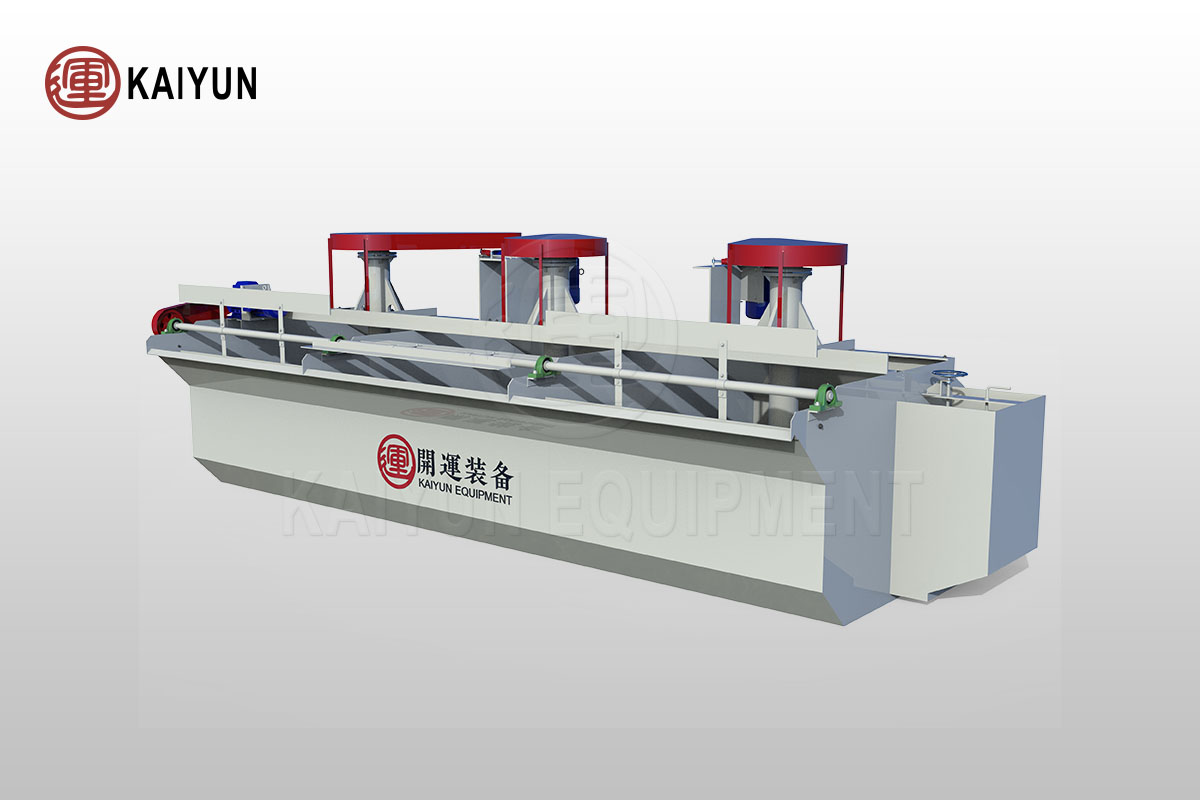

Floatation stage

In order to remove impurities such as iron, calcium and mica that may exist in the magnetic concentrate, separate the excess quartz in the ore and improve the concentrate grade, the magnetic concentrate will be floated to remove impurities and purify. For impurity minerals, Kaiyun usually uses a well-selective collector to obtain high-grade feldspar fine powder.

Process Flow Chart