Introduction

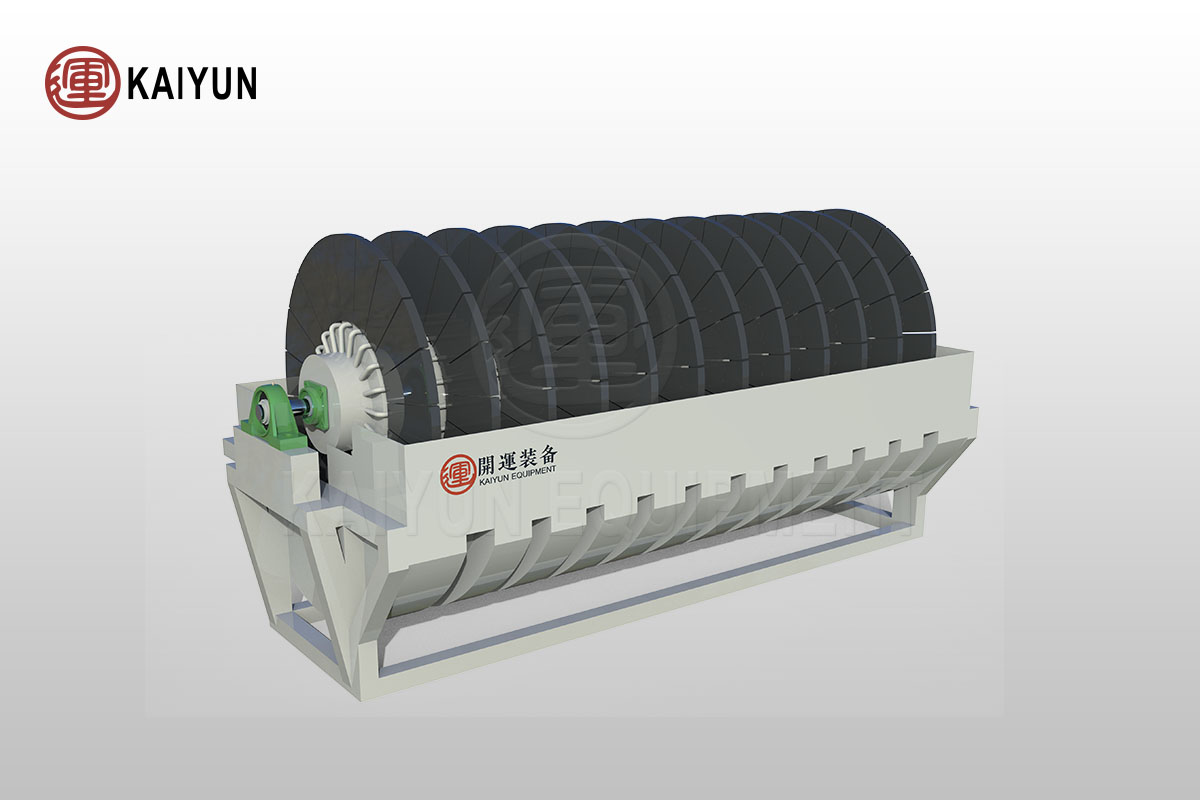

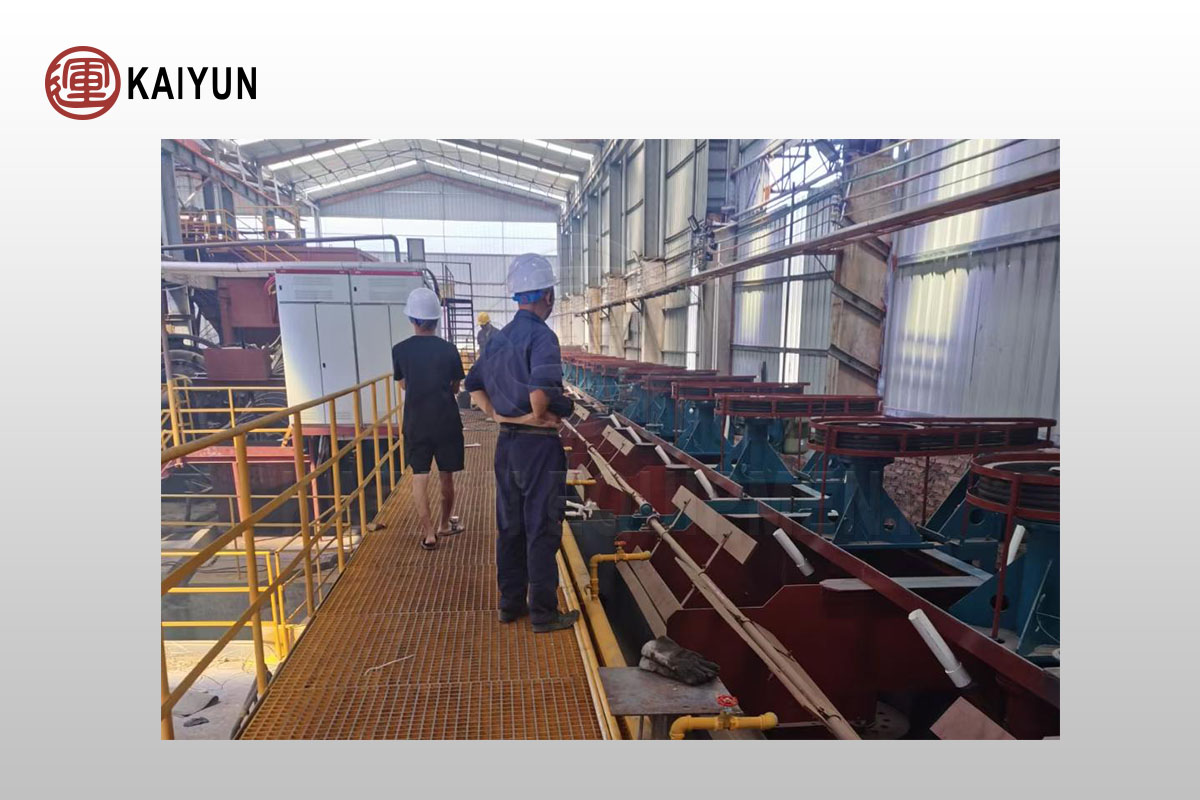

Fluorite beneficiation methods include gravity separation and flotation. Fluorite beneficiation equipment is also divided into gravity separation equipment and flotation equipment. Gravity separation equipment refers to jigs. Only jigs can process coarse-grained fluorite ore. Fluorite flotation equipment is similar to other mineral flotation equipment, including crushers, ball mills, flotation machines, etc.

Application Areas

Fluorite flotation process can be applied to fluorite ores with complex ore properties such as high mud content in the original ore, symbiosis of impurity minerals and fluorite, and fine particle size of useful minerals.

Table of Contents

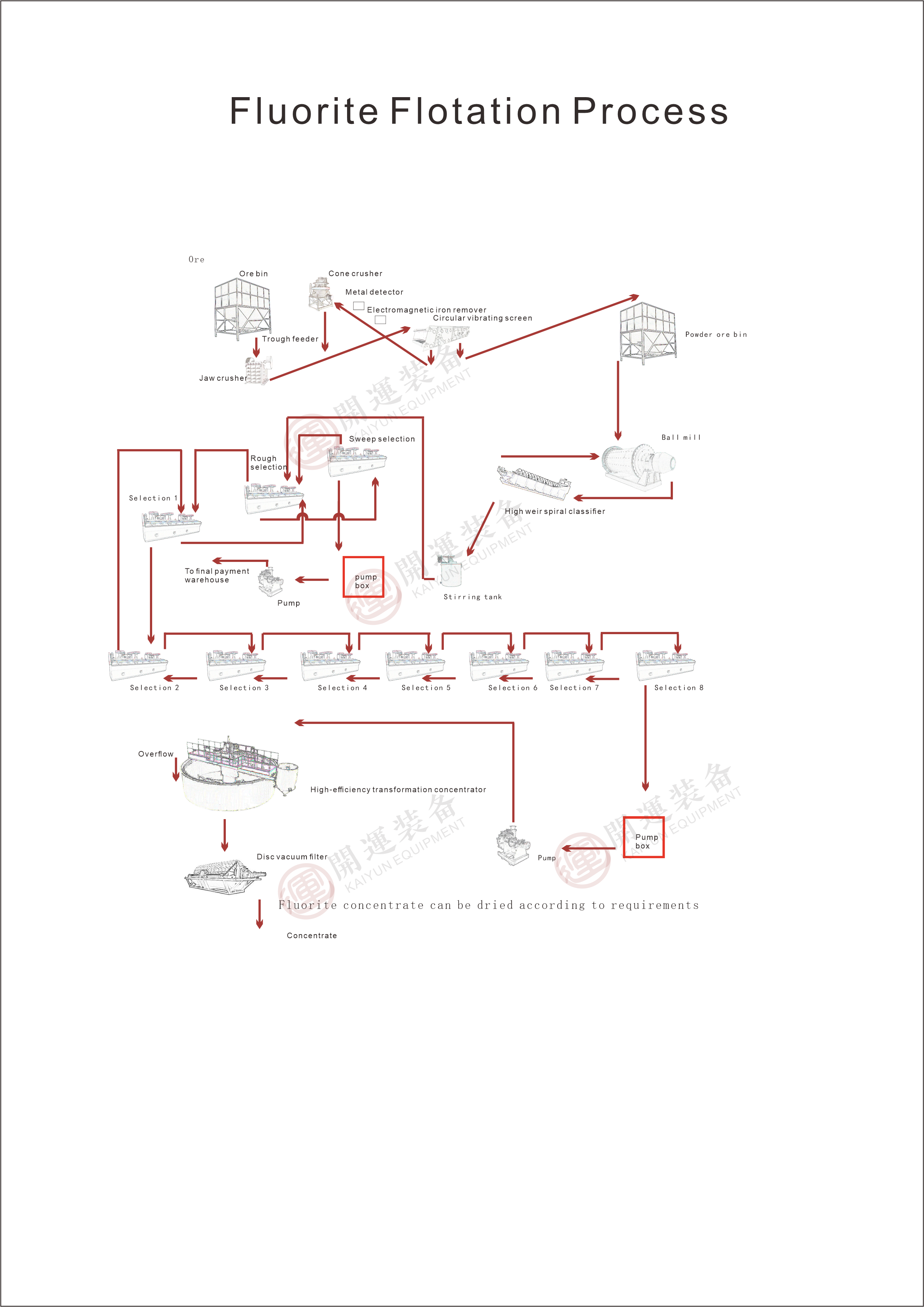

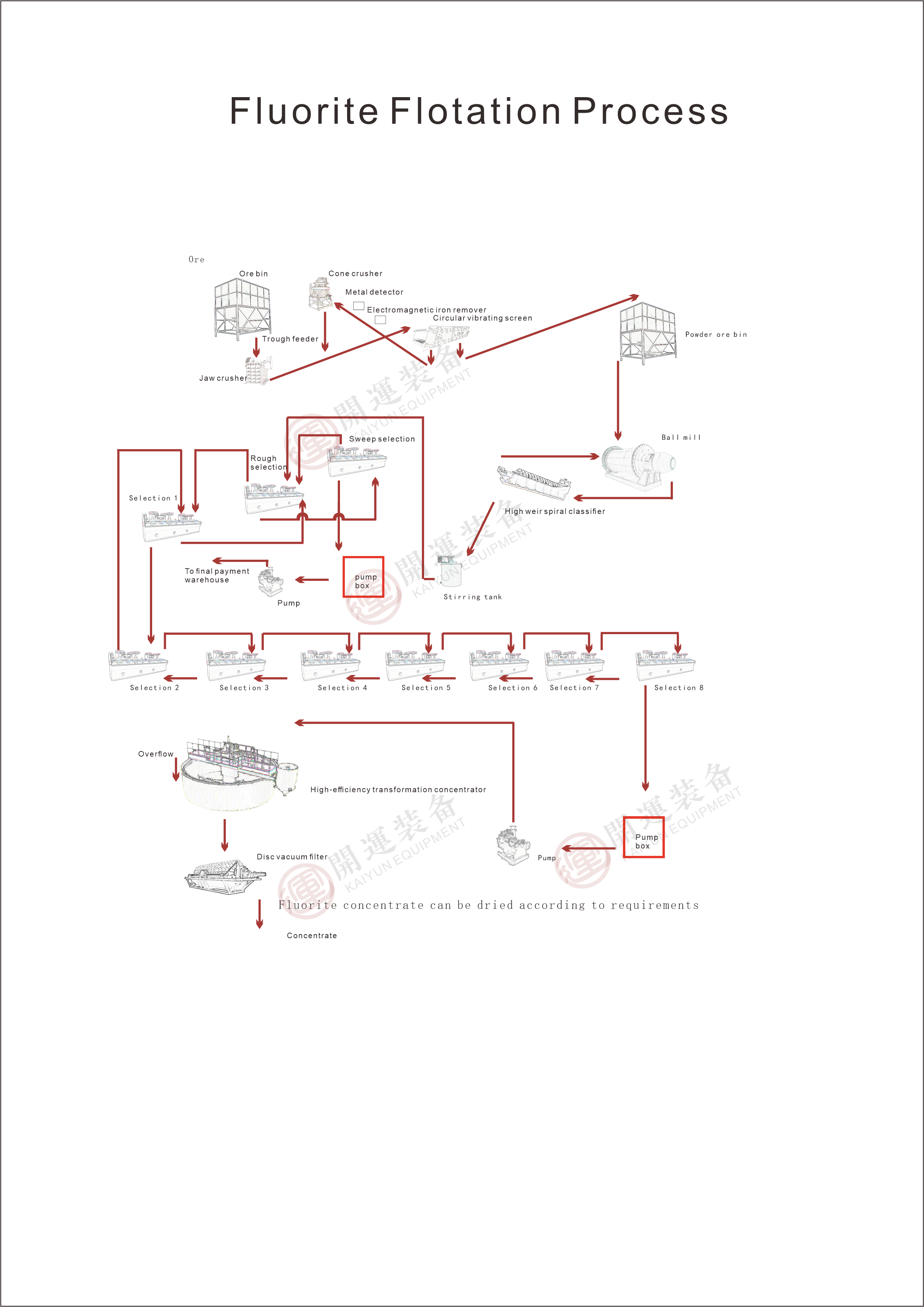

Process Flow

Fluorite ore has complex composition, and useful minerals are similar in properties to gangue minerals. It is generally treated by a combination of flotation, gravity separation and magnetic separation.

Separation of fluorite and barite

Fluorite and barite are generally mixed and floated, and then separated. Oleic acid is used as a collector to obtain mixed concentrate during mixed flotation. Mixed concentrate separation can be obtained by positive flotation or reverse flotation to obtain fluorite concentrate.

Separation of fluorite and quartz

Fluorite is collected with fatty acids, and quartz is inhibited with water glass. The amount of water glass should be properly controlled. A small amount can activate fluorite, but the inhibitory effect on quartz is insufficient. Excessive amount will inhibit fluorite. Sometimes, in order to enhance the inhibitory effect of water glass on quartz, certain multivalent metal ions are added, which not only inhibit quartz but also calcite.

Separation of fluorite and sulfide ore

For fluorite containing sulfide ore, xanthate collector is generally used to float out the sulfide ore, and then fatty acid collector is added to float fluorite. In the flotation operation of fluorite, a small amount of sulfide mineral inhibitor can also be added to inhibit the residual sulfide minerals to ensure the quality of fluorite concentrate.

Process Flow Chart