Introduction

Hematite is a weakly magnetic iron ore, and many beneficiation methods are used. Traditional beneficiation methods include roasting magnetic separation, flotation and strong magnetic separation, but the indicators of a single process are poor. Currently, a process combining centralized methods is mostly used.

According to the characteristics of hematite beneficiation process, it can be divided into roasting magnetic separation process, flotation process, weak magnetic-strong magnetic process, strong magnetic flotation process and gravity-magnetic-flotation combined process.

Application Field

The hematite beneficiation process can be applied to hematite and impurities with uneven particle size and high fine particle content, including a small amount of magnetite, and gangue minerals containing quartz, kaolin and other complex ore properties.

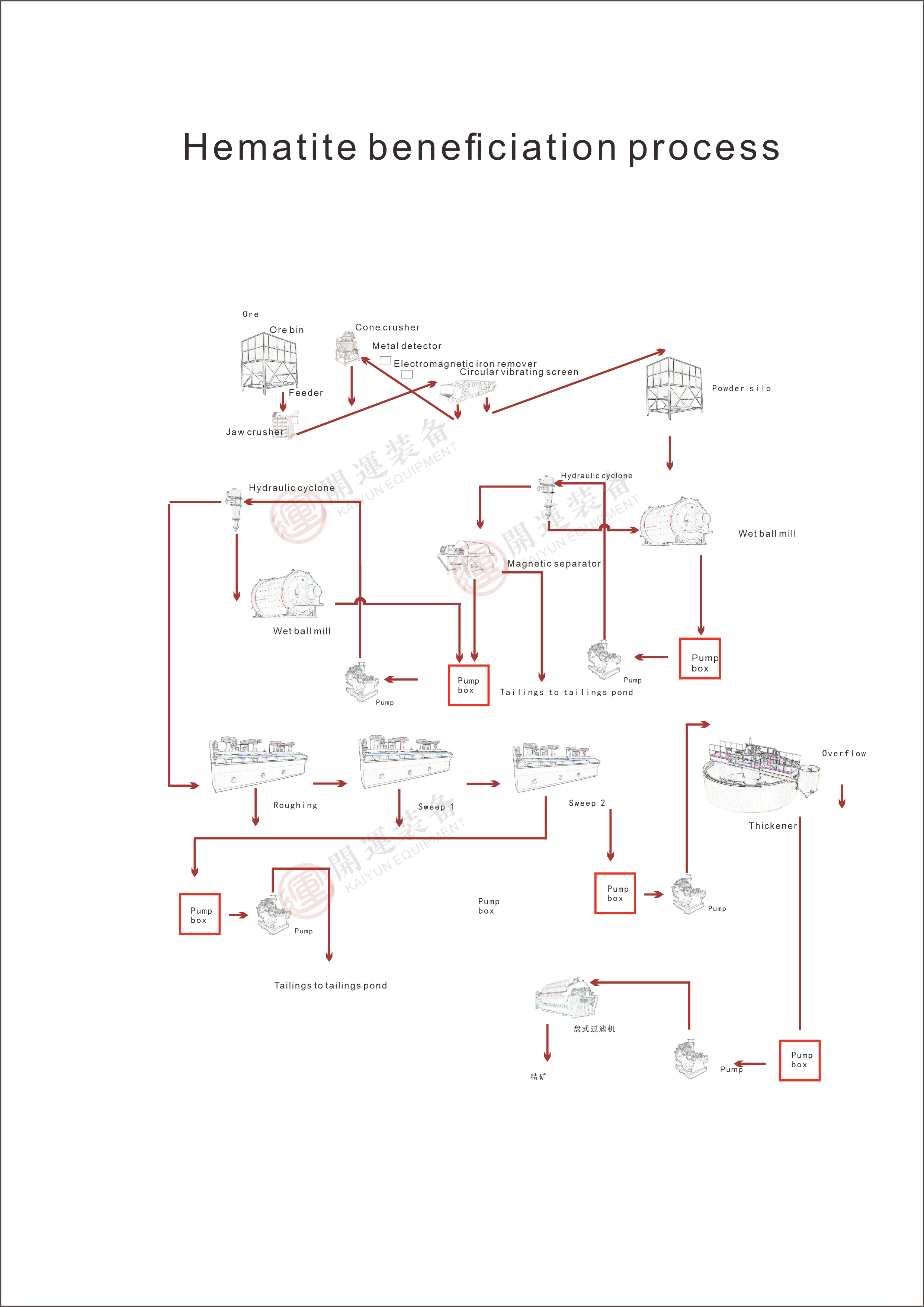

Process Flow

The first stage of grinding and classification uses a ball mill and a cyclone to form a closed-circuit grinding, which can ensure both classification efficiency and classification particle size; at the same time, some qualified concentrates can be selected in advance. And through the high gradient magnetic separator, some low-grade tailings can be discarded, which can not only reduce the amount of medium ore re-grinding, but also avoid over-grinding and reduce metal loss.

The magnetic separation operation timely sorts out qualified coarse-grained concentrates and tailings, which conforms to the principle of early collection and early abandonment, and reduces the amount of flotation operations and reduces costs.

The strong magnetic process can recover fine-grained iron minerals, which can play a dual role of desludging and tailings discarding, creating better conditions for flotation operations;

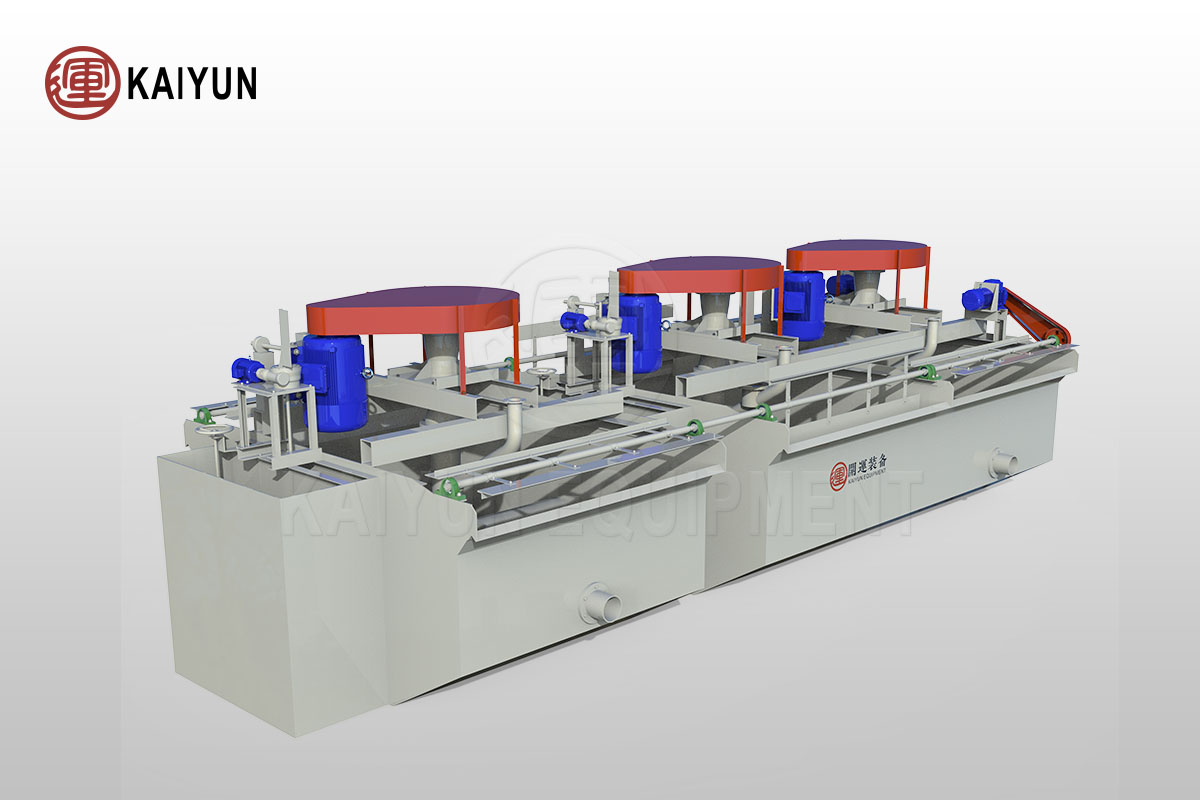

The reverse flotation process has a simple reagent system, which can significantly reduce the entry of organic matter such as flotation reagents into the ore pulp, reducing its adverse effects on the flotation process.

Process Flow Chart