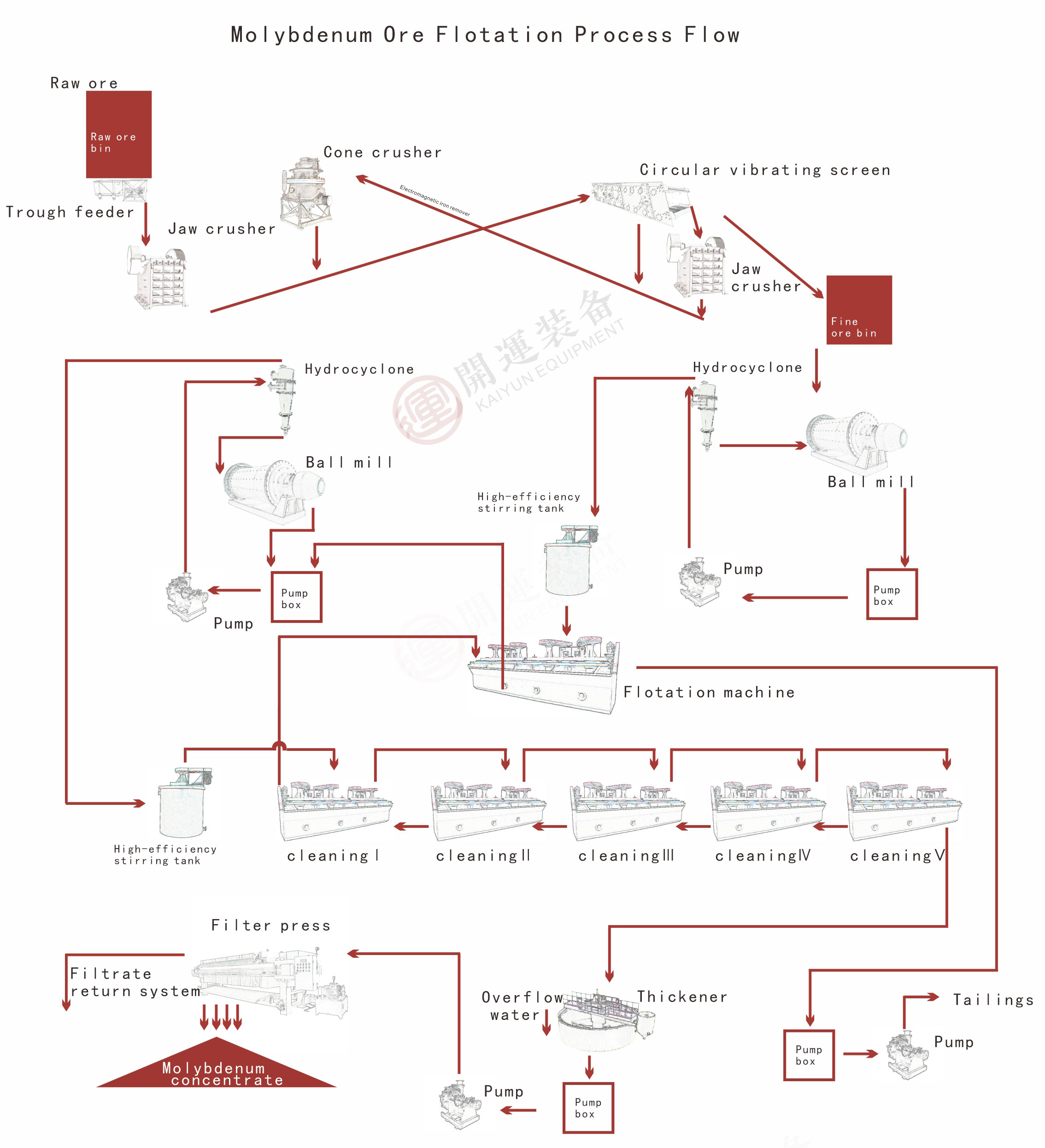

Overview

The molybdenum ore beneficiation process mainly improves the quality of the concentrate through regrinding and re-selection. According to different ore characteristics, the most suitable regrinding process is selected to optimize the mineral processing effect. This process can reduce energy consumption by about 30% and significantly increase the recovery rate by more than 10%.

Application scope

The molybdenum ore beneficiation production line is suitable for single molybdenum ores or complex ores, especially those refractory molybdenum ores that are closely symbiotic with sulfide minerals and have finer particle sizes.

Table of Contents

Craft details

1. Stage grinding to improve concentrate quality

– In the coarse grinding stage, mixing and roughing are carried out first, and then the resulting coarse concentrate is reground and further refined.

– By reducing the amount of regrinding coarse concentrate, it promotes the monomer dissociation of minerals, thereby improving the grade and recovery rate of the concentrate while reducing energy consumption.

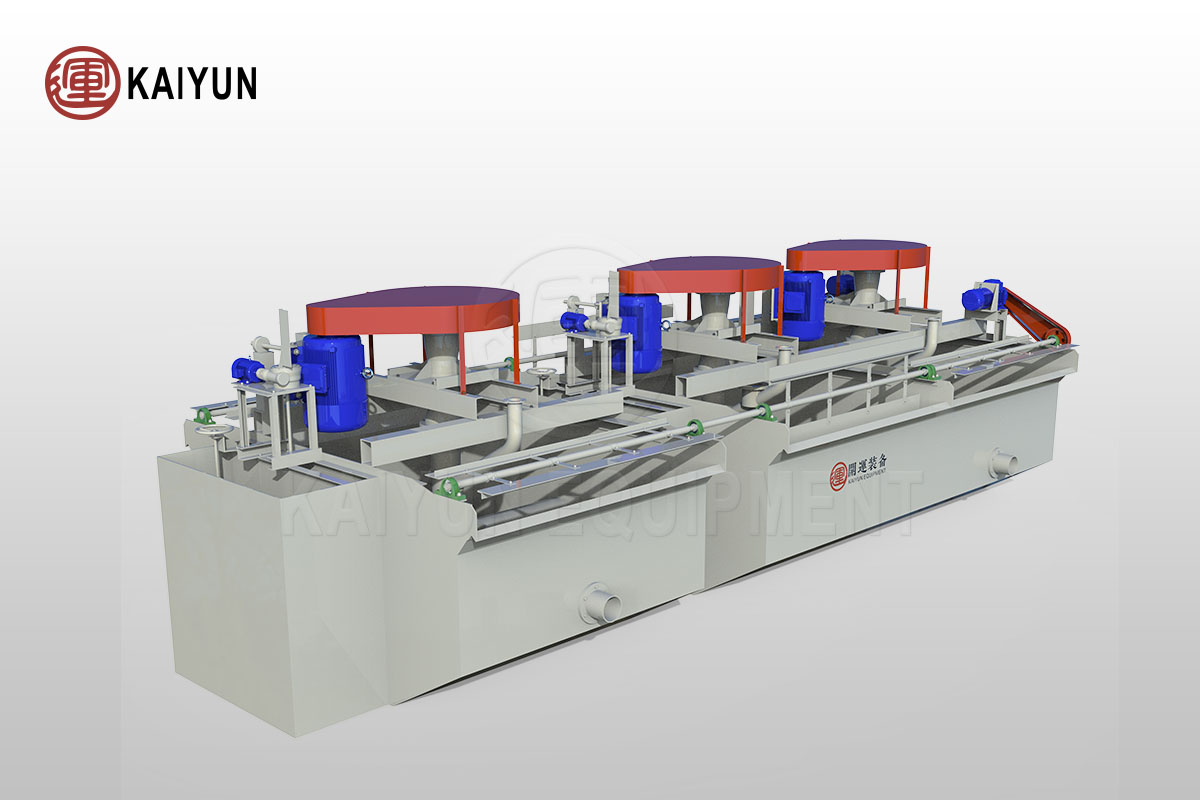

2. Strengthen flotation and improve the grade of molybdenum concentrate

– Strictly implement the pharmaceutical system during the rough selection stage and accurately control the dosage of pharmaceuticals to achieve the principle of “harvest early if possible” and reduce multiple cycles and unnecessary losses.

– Utilize the secondary enrichment effect of foam and properly replenish water to clean the concentrate foam to reduce impurities in the foam and enhance the flotation effect.

3. Stage selection to ensure recovery rate

– Adopt stage separation method to recover useful minerals of different particle size levels, thereby improving the overall quality index of the concentrate.

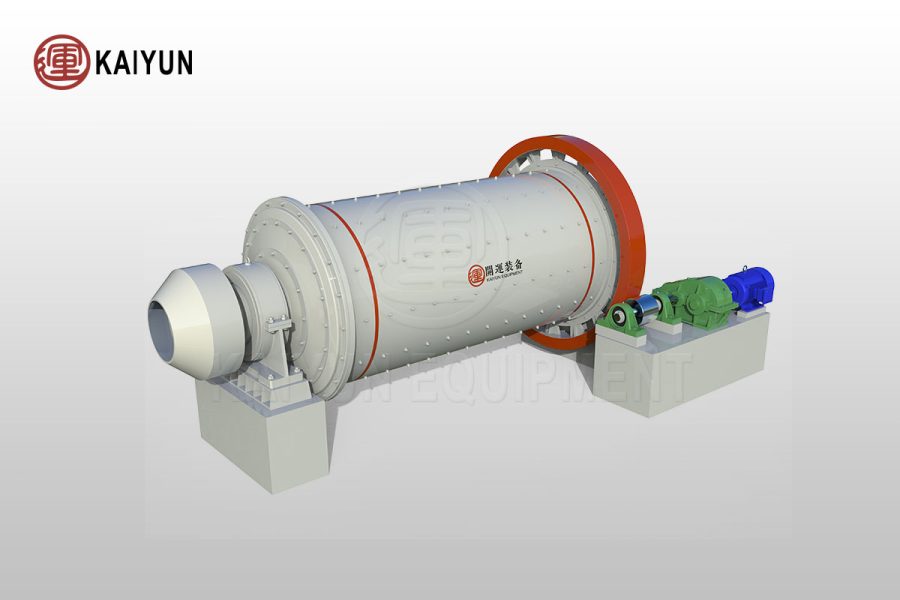

4. Combination of equipment and technology

– Configure appropriate production equipment according to the needs of the production process to ensure coordination between equipment and process flow.

Process flow chart