Introduction

Quartz sand is a silicate raw material obtained by crushing and purification. Due to its high hardness, wear resistance and stable chemical properties, quartz sand is often used in ceramics, glass, casting, construction, chemical industry, abrasives and other fields. Natural quartz sand will contain various impurities, and can only be used after being purified by a certain process.

The quartz sand process mainly includes quartz sand impurity analysis and impurity removal process, quartz sand purification process, etc.

Table of Contents

Application Field

The quartz sand production process can be applied to quartz sand containing iron or mica.

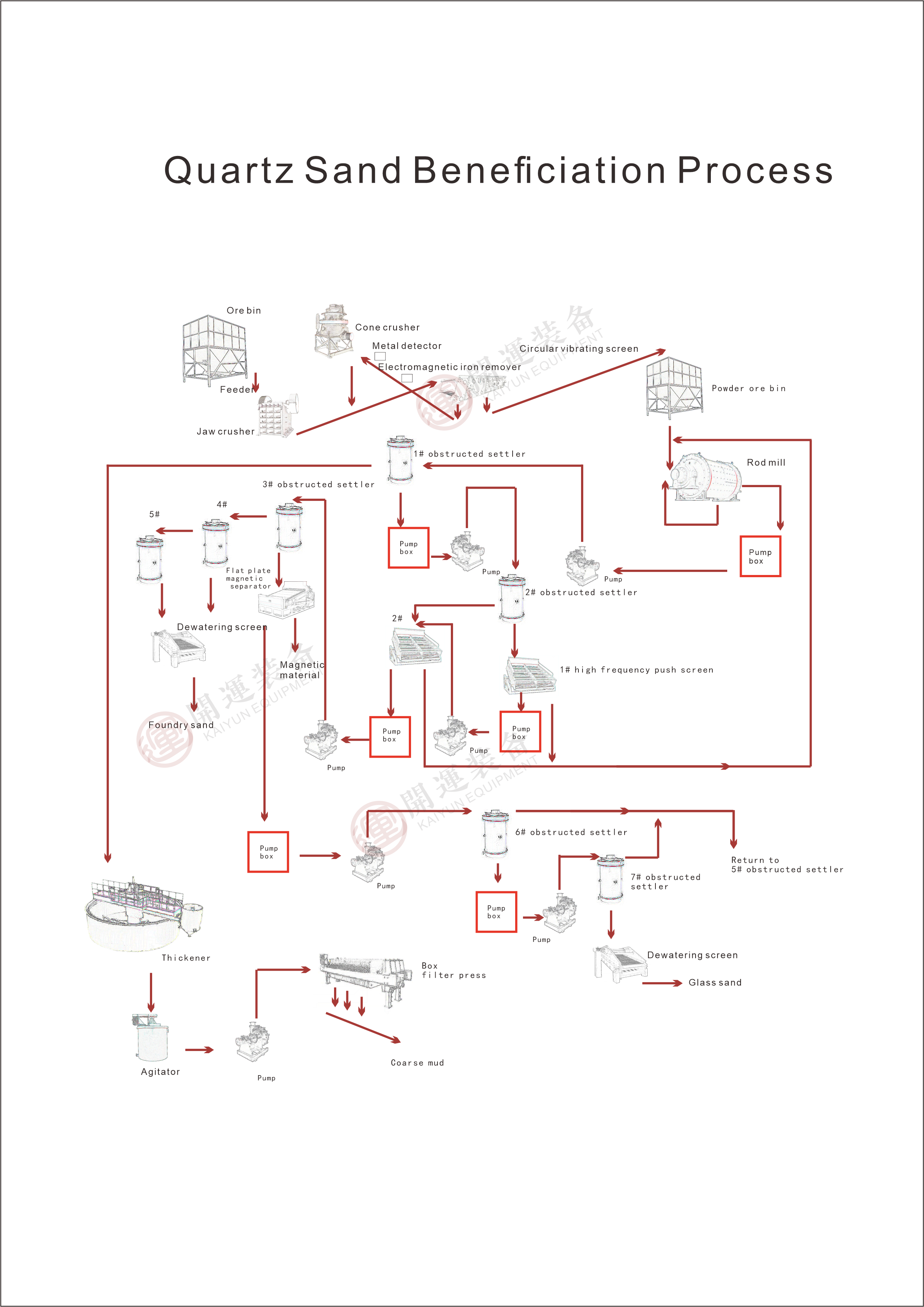

Process Flow

Rough selection

Remove obvious impurities and foreign matter from various quartz ores.

Crushing

Use jaw crusher and cone crusher to crush the quartz ore.

Water washing, classification and desludging

The grade of SiO2 in quartz sand decreases as the quartz sand particle size becomes finer, while the grade of impurity minerals is the opposite. This phenomenon is particularly obvious in quartz sand containing a large amount of clay minerals, so it is very necessary to wash and desludging the quartz sand ore before selection.

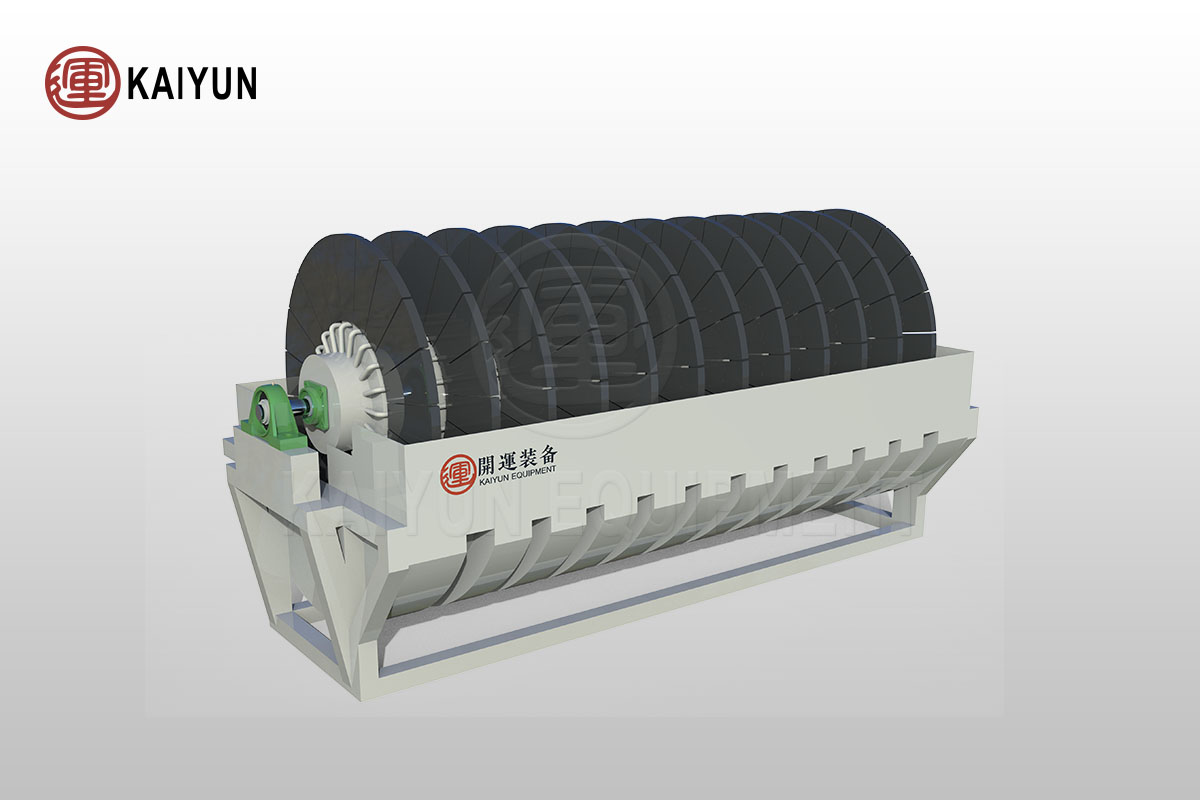

Scrubbing

Scrubbing is to use mechanical force and the abrasive force between sand particles to remove the thin film iron and muddy impurities on the surface of quartz sand and further rub the unformed mineral aggregates, and then achieve the effect of further purification of quartz sand through classification. At present, there are two main methods: rod grinding and mechanical scrubbing.

Flotation

According to the different physical and chemical properties of the surface of mineral particles, the minerals are sorted according to the difference in floatability. The main function of flotation is to remove mica, feldspar, and iron-containing mineral impurities in quartz sand.

Acid leaching

It is mainly to remove metal oxides and some silicate minerals soluble in acid. Acid leaching is one of the important processes in the purification process of high-purity quartz sand. Whether it is the preparation of quartz glass for electric light sources or the preparation of quartz raw materials for photovoltaic and semiconductor devices, the acid leaching process must be used.

Process Flow C