Process Introduction

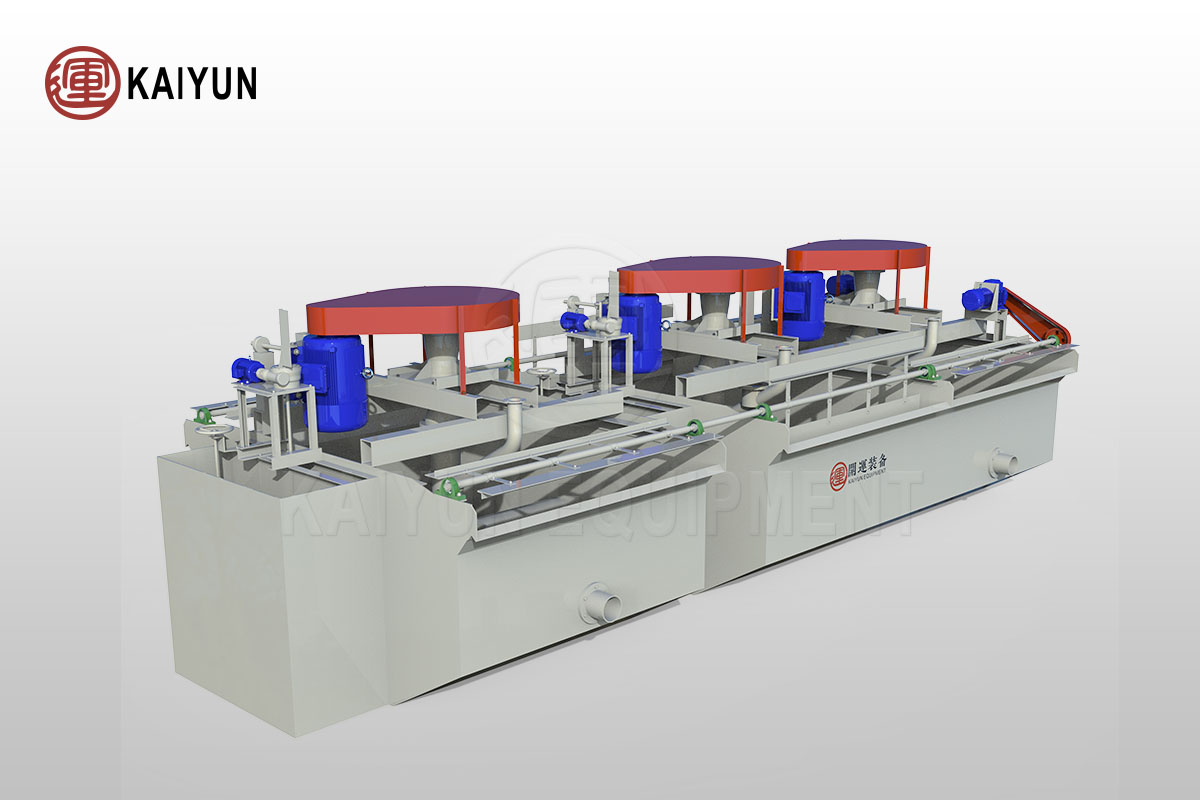

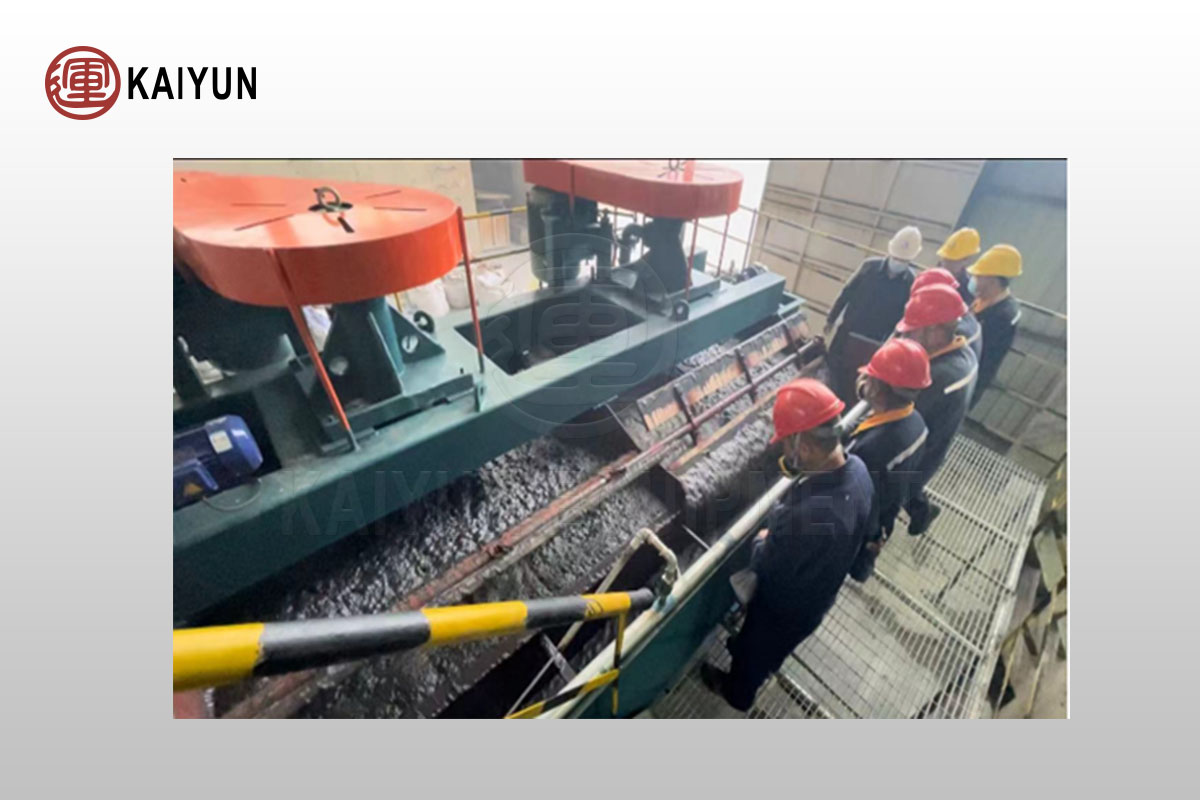

Scheelite beneficiation can be performed using various methods such as gravity separation, magnetic separation, and flotation. Scheelite has good floatability, but it often occurs with calcium-bearing gangue minerals that have similar properties, making the flotation process relatively complex. The beneficiation methods and processes used vary according to the type and properties of the ore.

Application Field

The flotation process for scheelite is suitable for ores containing various other metallic and non-metallic minerals, especially those where the valuable minerals are closely associated with gangue minerals and have a complex structure.

Table of Contents

Process Details

Separation of Scheelite from Calcite and Fluorite

Typically, the process uses concentrated pulp and high temperature. The pulp is concentrated to a density of 60%-70%, and then sodium silicate is added. The pulp is heated to 80°C, stirred for 30-60 minutes, then diluted with clean water. Scheelite is floated at room temperature, with the remaining product in the cell being fluorite and calcite.

Separation of Scheelite from Barite

Since sodium silicate has a similar inhibitory effect on both scheelite and barite, separation is difficult with just sodium silicate. Alkyl sulfate is used as a collector under conditions of pH 1.5-3.0 to repeatedly separate barite, resulting in scheelite being left in the cell.

Separation of Scheelite from Sulfide Minerals

Before floating scheelite, sulfide minerals are collected using xanthate. During scheelite flotation, a small amount of oxides and sodium sulfide is added to inhibit any remaining sulfides that were not floated out.

Separation of Scheelite from Quartz Silicates

Oleic acid is used as a collector, and sodium silicate is used as an inhibitor to suppress quartz and silicate gangue minerals, allowing scheelite to be floated.

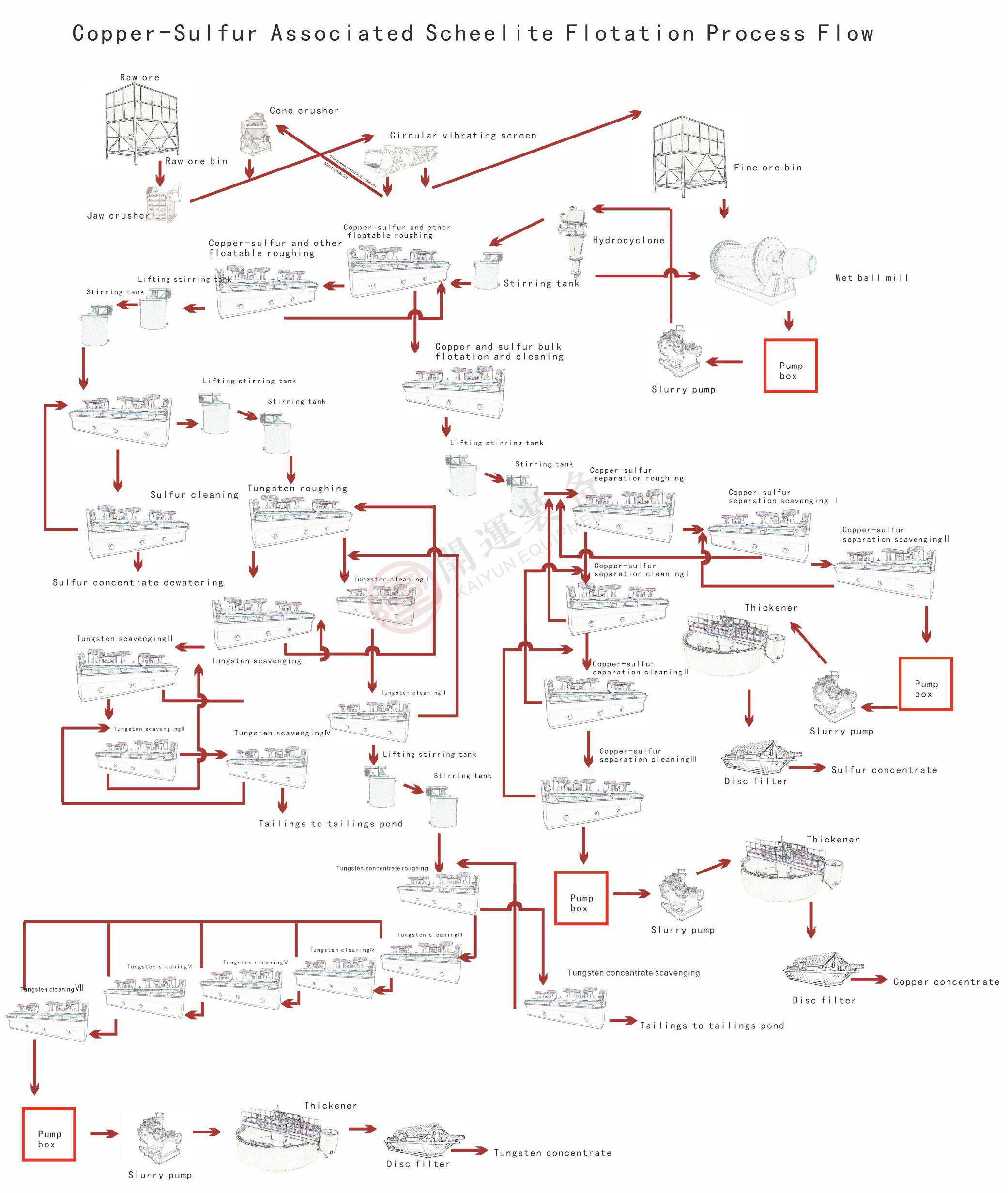

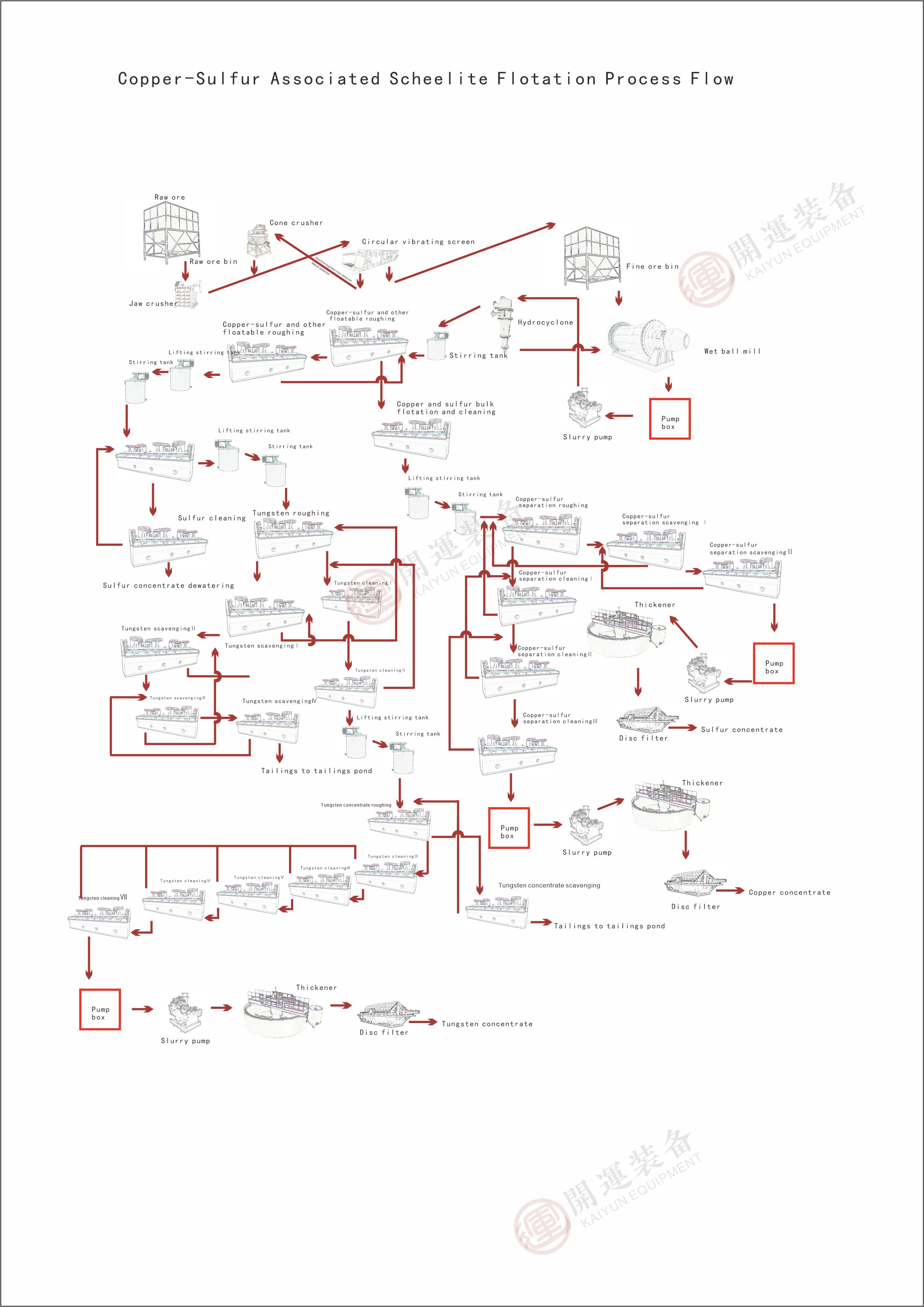

Process Flow Chart