Introduction

Tails dry discharge is a new tailings treatment process that has emerged in recent years. The tailings slurry discharged after beneficiation is concentrated in multiple stages and then treated by a series of high-efficiency dehydration equipment to form slag with low water content, easy precipitation and solidification, and can be stored on site. The slag can be sold as a building material or transported to a fixed location for dry storage.

The tailings dry discharge process can alleviate the storage capacity pressure of the tailings pond, reduce the safety hazards of the tailings pond, and increase the means of tailings reuse. It is a tailings treatment process to achieve green and environmentally friendly mines.

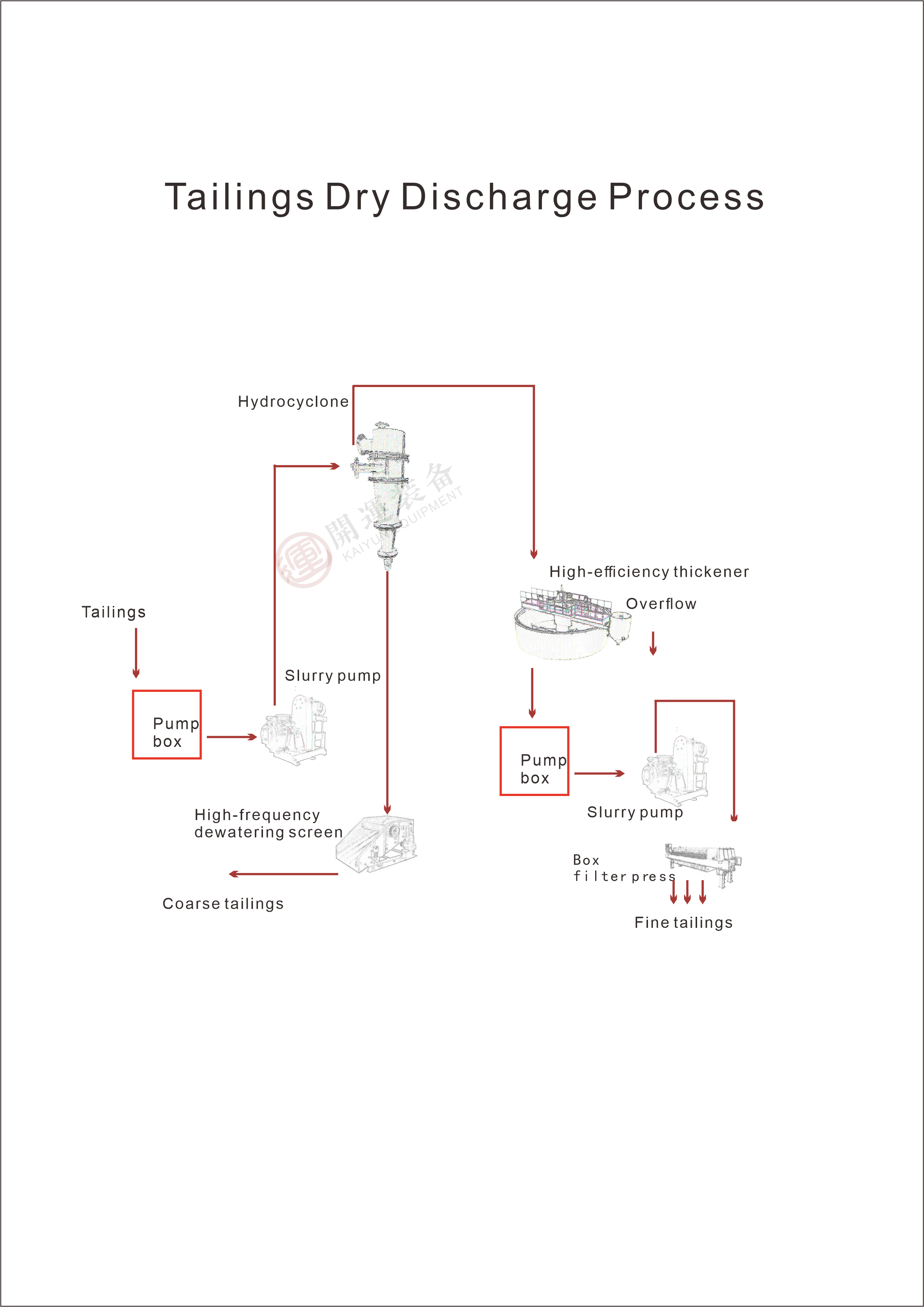

Process Flow

The tailings dry discharge process system is mainly composed of slurry pumps, hydrocyclones, high-efficiency transformation thickeners, high-frequency and high-efficiency dehydration screens, chamber filter presses and slurry conveying devices.

The tailings slurry is pumped to the hydrocyclone for concentration and classification, where the sediment enters the high-efficiency high-frequency dehydration screen for dehydration, and the overflow enters the high-efficiency transformation thickener for concentration.

The coarse tailings treated by the dewatering screen are directly transported to the material yard by the conveyor for storage. The tailings treated by the concentrator enter the filter press for filtration and dehydration, and the filter cake is automatically unloaded to the conveyor and sent to the material yard for storage.

Process Advantages

1. Good dehydration effect, high safety, and environmental friendliness.

2. Small footprint, low energy consumption, and low production and operation costs.

3. Low investment, great social and economic benefits.

Process Flow Chart