Introduction

Tailings reselection technology is an inevitable choice in the current context of increasing scarcity of mining resources. The comprehensive utilization of tailings requires the design of a reasonable tailings reselection treatment process based on the different properties of each tailing, and targeted development and utilization on this basis, in order to achieve high added value of tailings.

Application Field

Tailings reselection technology is suitable for the reselection of various metal and non-metal tailings, including iron, gold, lead and zinc, copper, fluorite, tungsten, phosphorus, graphite, bauxite tailings, etc.

Table of Contents

Process Introduction

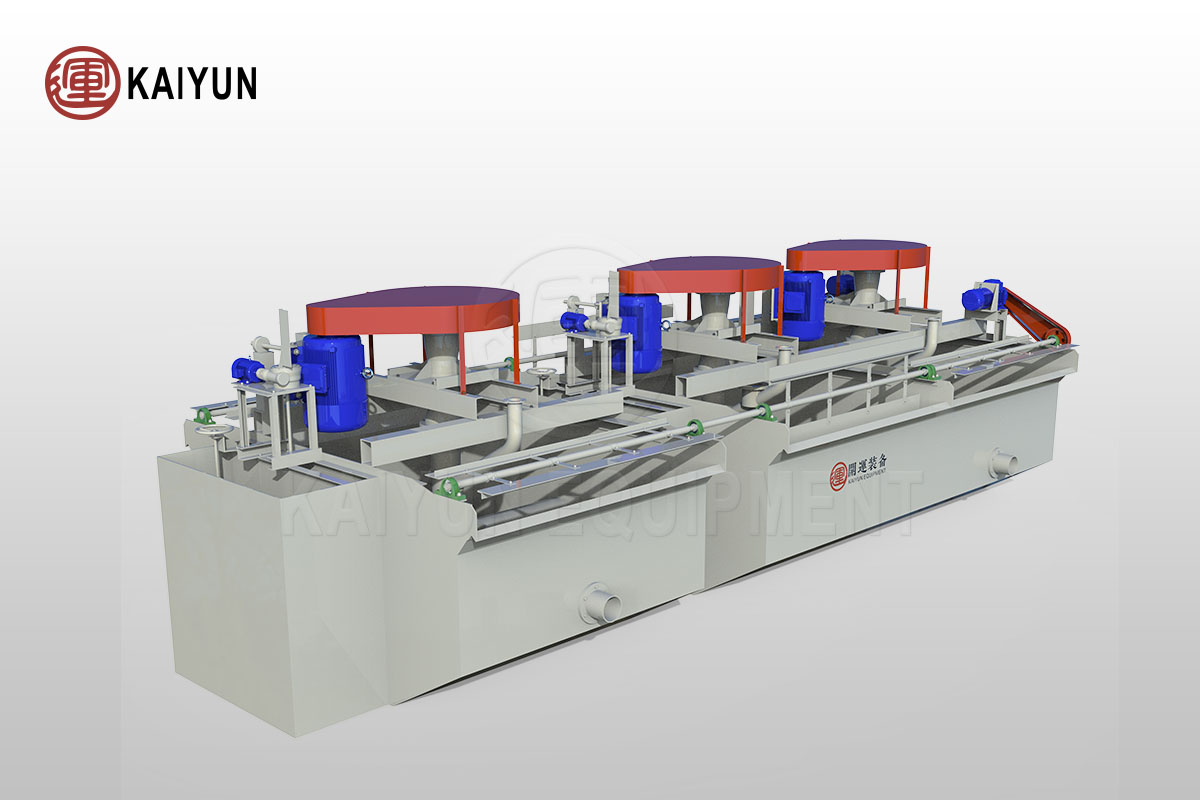

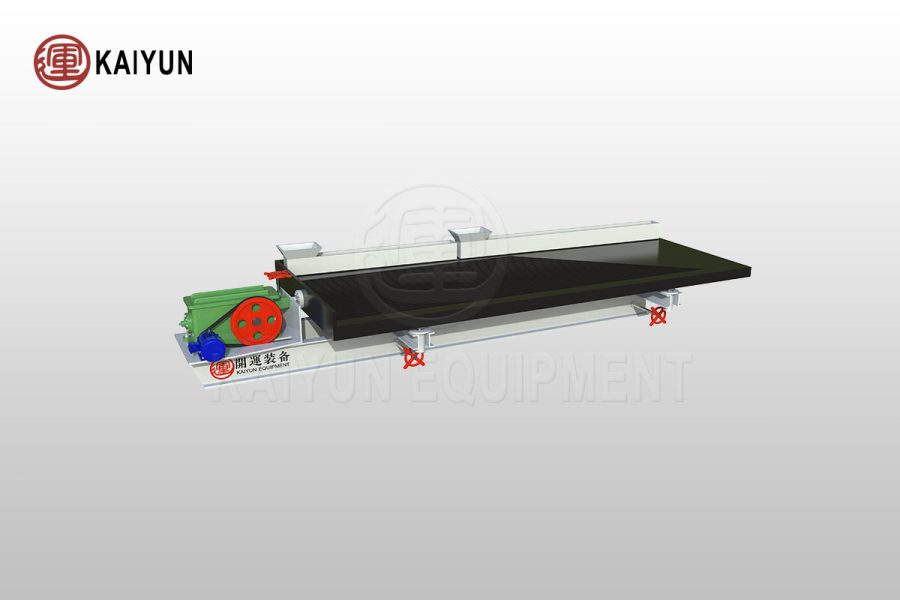

In the reselection of tailings, the commonly used purification methods include gravity separation, magnetic separation, flotation and microbial treatment. Among them, flotation technology is often used as the main method of tailings reselection. After flotation reselection, not only can high-quality concentrate products be obtained, but also the final tailings output can be greatly reduced, reducing the pressure of tailings on the environment.

For example: quartz is associated with kaolin ore, and this part of the associated quartz ore is treated as tailings with the production of kaolin. After kaolin tailings are scrubbed, ground, screened, re-selected, magnetically separated and flotated, high-quality quartz sand products can be obtained.

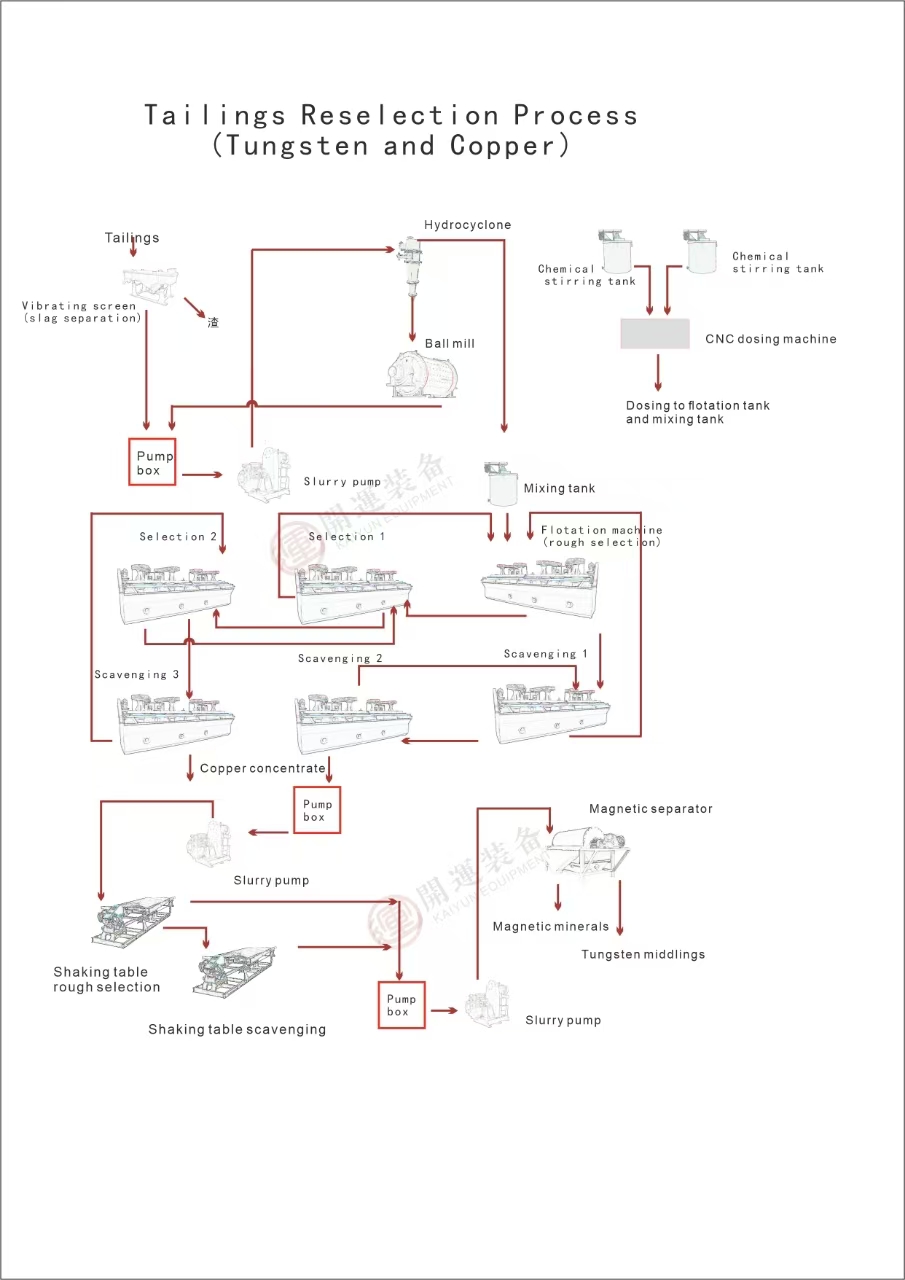

Process Flow Chart