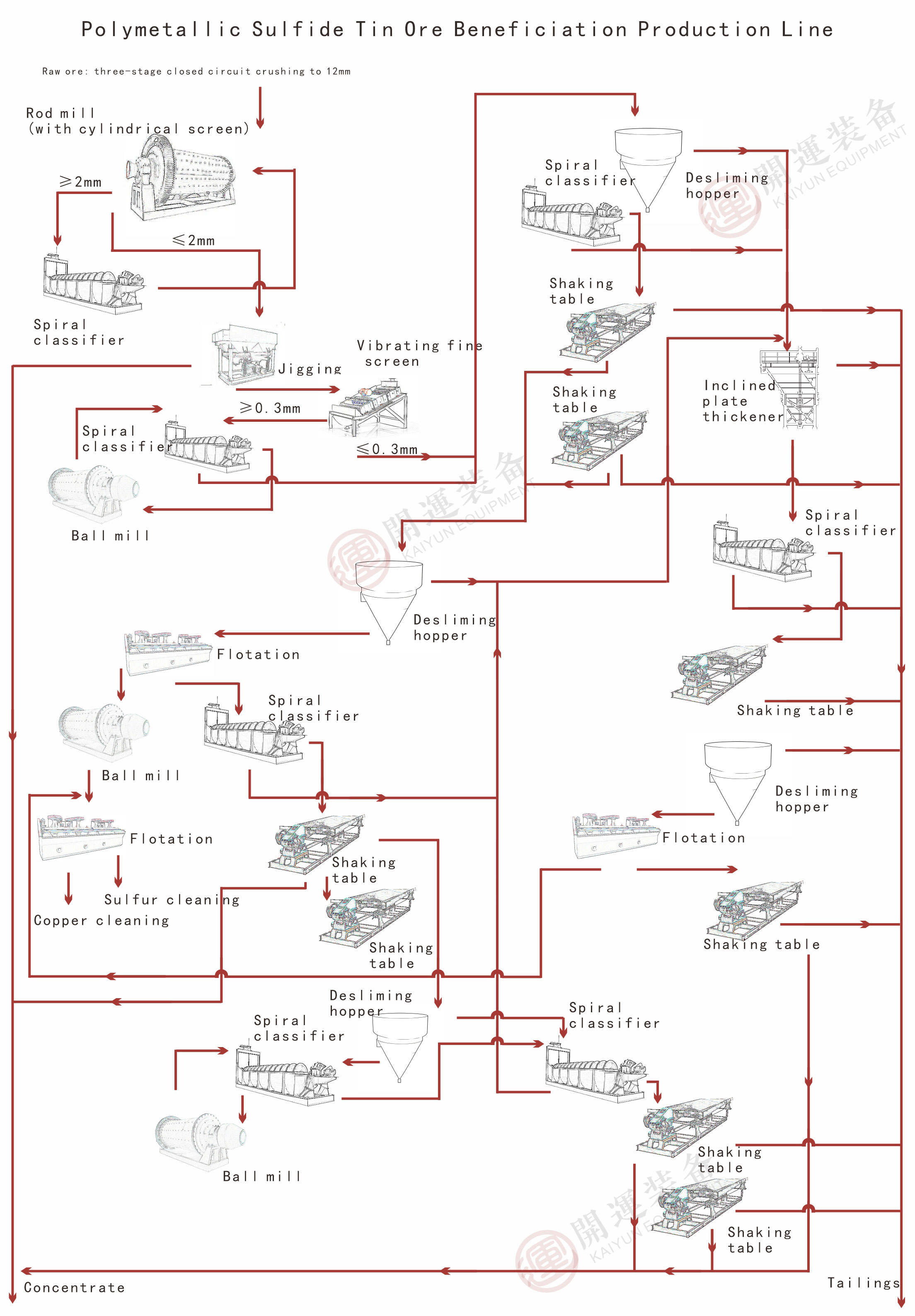

Process Introduction

Tin ore is usually separated by gravity separation because its density is greater than that of paragenetic minerals. However, since the ore may contain various iron oxide minerals (such as magnetite, hematite, etc.), these minerals are difficult to be effectively separated from tin ore by gravity separation or flotation, so magnetic separation or flotation is also required.

Application Field

Gravity separation is widely used to treat tungsten, tin, and gold ores, especially the traditional method of placer gold and placer tin ores. It is also very common in the treatment of placer ores containing rare metals (niobium, tantalum, titanium, zirconium, etc.). In addition, gravity separation is also used to separate weakly magnetic iron ore, manganese ore, chromium ore, etc.

Table of Contents

Process Details

1. Crushing and Screening

– The raw ore is crushed to 20mm, and then screened into two particle sizes of 20-4mm and 4-0mm.

2. Pre-selection

– The 20-4mm ore enters the heavy medium cyclone for pre-selection.

– The pre-selected product is then pre-selected by a jig after passing through a rod mill.

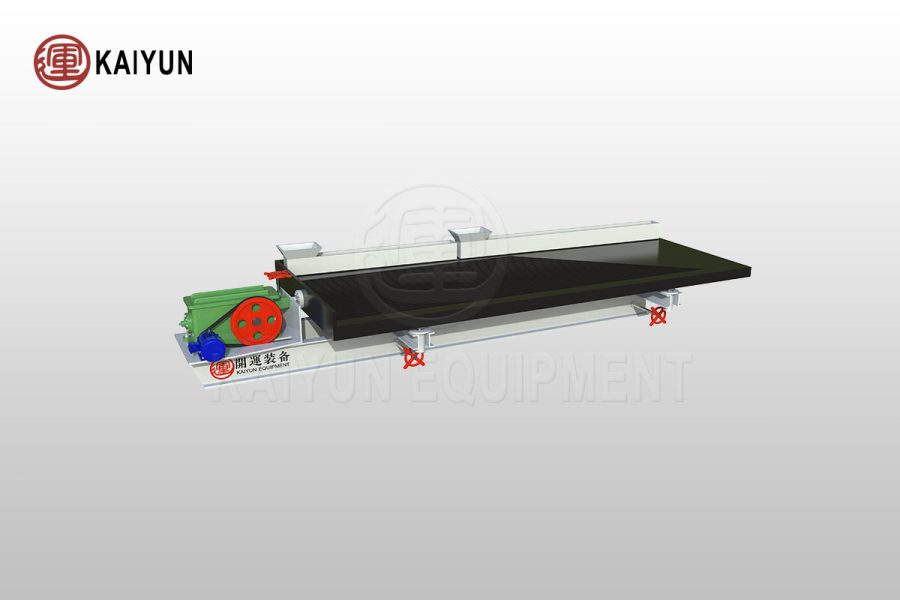

– The jigging tailings are screened out with a 2mm vibrating screen to remove +2mm as waste tailings, and -2mm enters the shaking table for selection.

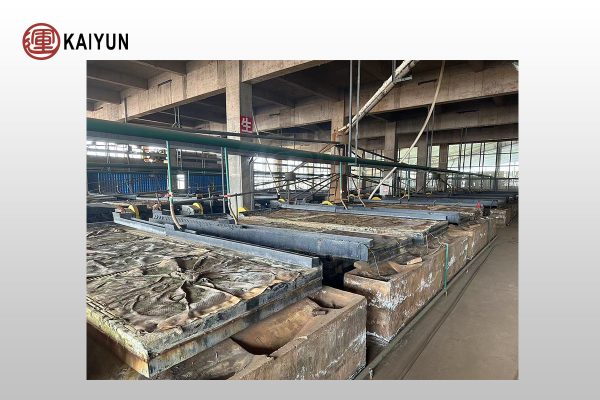

3. Flotation

– The jig and shaking table concentrates are ground separately and then mixed for flotation.

– The mixed flotation tailings are separated by a shaking table to produce qualified tin concentrate.

– The mixed flotation concentrate is then finely ground for lead and zinc separation flotation, and lead antimony concentrate and zinc concentrate are produced respectively.

4. Gravity selection

– The ore mud enters the Φ300mm cyclone.

– The overflow is then removed by a Φ125mm and Φ75mm hydrocyclone group to remove fine mud.

– The sediment is concentrated, flotated and desulfurized, and then cassiterite is flotated.

Process Flow Chart