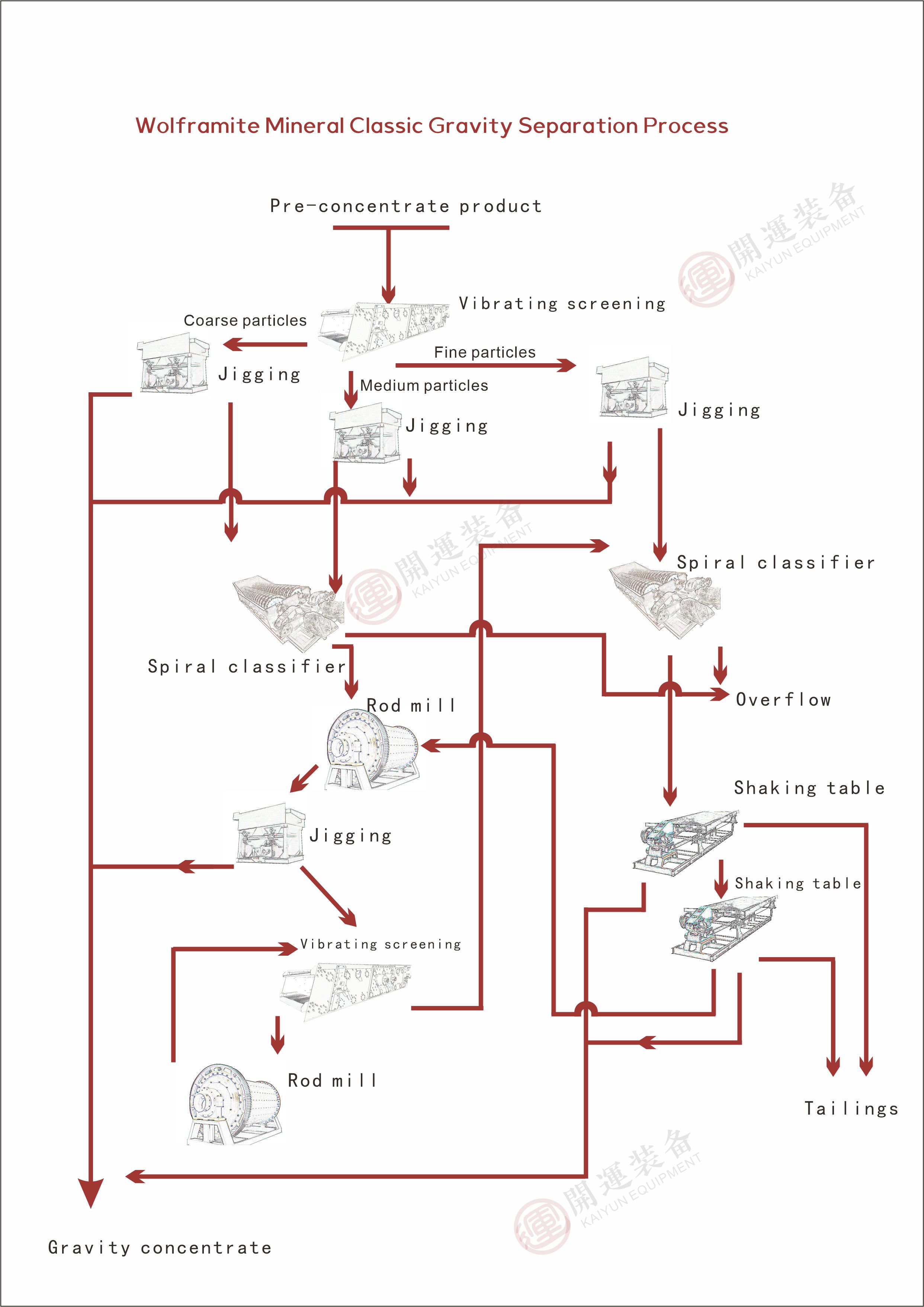

Process Introduction

Wolframite typically appears in quartz vein-type or fine vein-type tungsten deposits, with a relatively coarse grain size that is easy to separate. For this type of ore, a combined beneficiation process focused on gravity separation is adopted, mainly including four stages: coarse concentration, gravity concentration, fine concentration, and fine sludge treatment

Application Field

Wolframite beneficiation technology is especially suitable for ore with unevenly distributed grain sizes.

Table of Contents

Process Details

Coarse Concentration

For some wolframite beneficiation plants, mining technology companies apply the movable screen jigging machine in the first stage of fine grain coarse concentration, which then directly enters the fine concentration operation.

Gravity Concentration

The gravity concentration of black wolframite usually adopts a multi-stage jigging, multi-stage shaking table, and regrinding process.

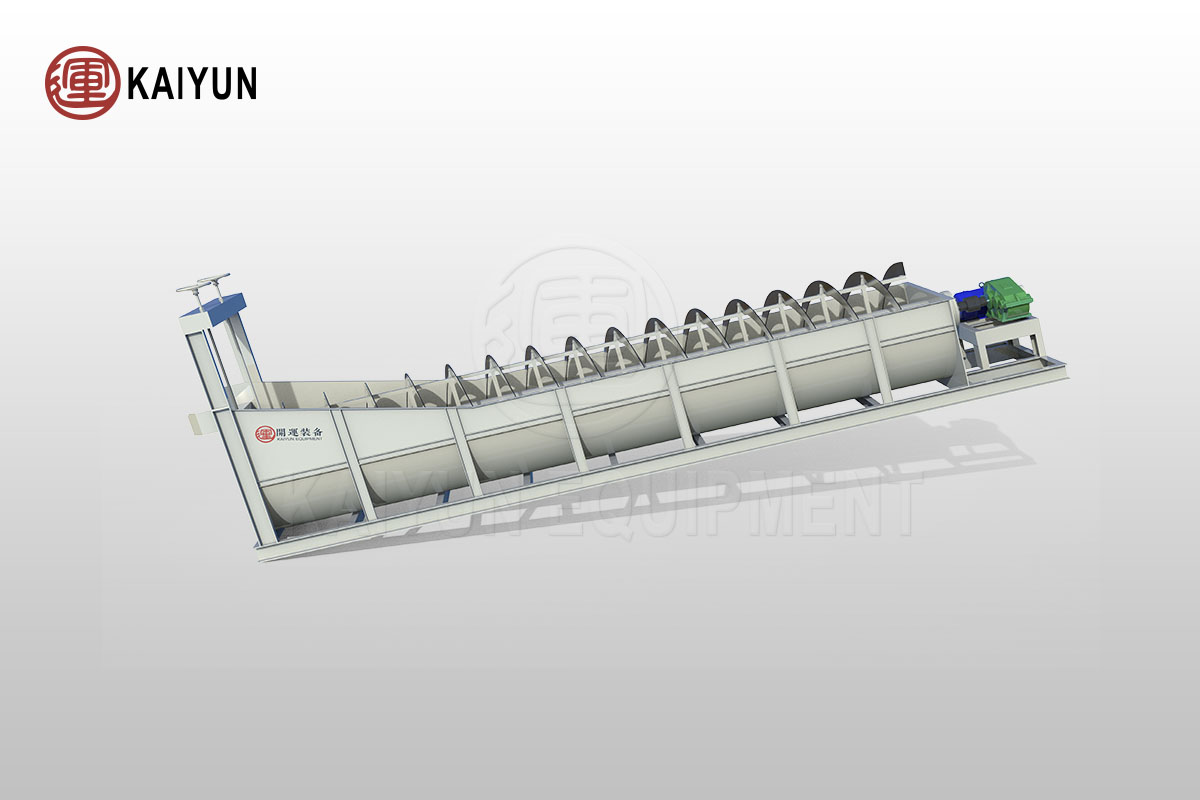

Qualified ore after fine crushing is classified by vibrating screens and then subjected to multi-stage jigging, producing jigging gravity concentration rough sand;

Coarse-grain jigging tailings enter the mill for regrinding;

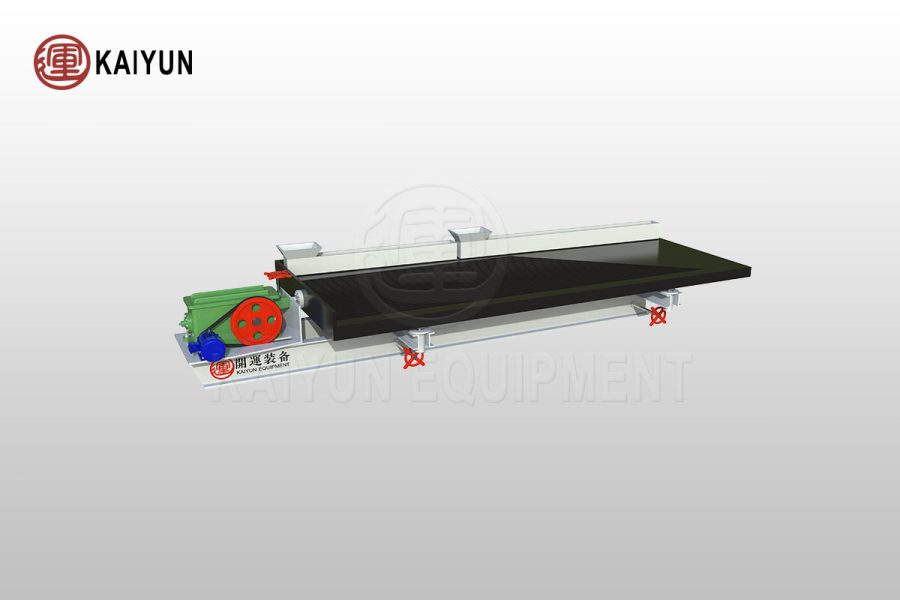

Fine-grain jigging tailings are classified by classifiers and then enter multi-stage shaking tables for separation, producing shaking table gravity concentration rough sand;

Shaking table tailings are discharged into the tailings reservoir, and shaking table middlings return for regrinding and re-separation;

The gravity concentration rough sand from jigging and shaking tables enters the fine concentration operation.

Fine Concentration

The fine concentration operation generally adopts various separation processes combining flotation and gravity or flotation, gravity, and magnetic separation, and recovers associated elements in the fine concentration stage.

Through coarse and fine-grain table flotation (a method combining flotation and shaking table) and flotation to remove sulfide minerals;

Table flotation and machine flotation sulfide minerals are combined and enter sulfide mineral flotation separation;

Table flotation and machine flotation black tungsten ore is further separated by gravity to produce black tungsten concentrate;

If the wolframite concentrate contains scheelite and cassiterite, it is separated by gravity, flotation, or gravity, flotation, and magnetic separation (electrostatic separation, etc.) to produce wolframite concentrate, scheelite concentrate, and tin concentrate.

Fine Sludge Treatment

Fine sludge treatment usually first involves desulfurization, followed by the recovery of wolframite minerals using gravity separation, flotation, magnetic separation, electrostatic separation, or combined separation processes according to the characteristics of the fine sludge material, along with the comprehensive utilization of associated metal minerals.

Process Flow Chart