High-Efficiency Agitation Tank

The high-efficiency agitation tank, designed specifically to enhance slurry circulation, ensuring achieving perfect integration.

Ordinary Agitation Tank

The ordinary agitation tank is widely used for the mixing of slurry and reagents before flotation operations.

Chemical Reagent Agitation Tank

The Chemical Reagent Agitation Tank, specifically designed for reagent preparation prior to mineral flotation operations, represents the culmination of fine chemistry and modern mining technology.

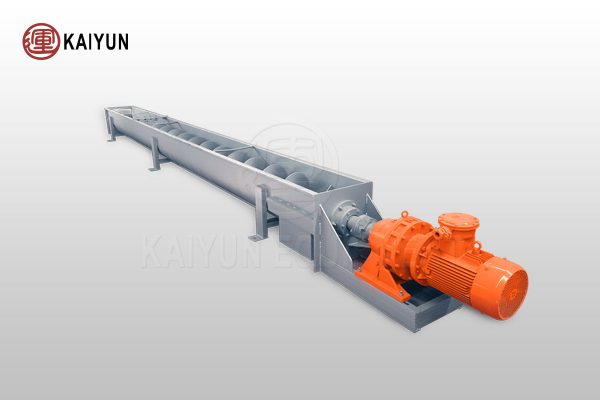

Screw Conveyor

The screw conveyor is widely used for the conveyance of powdery, granular, and small-sized materials such as ore powder, coal powder, soda ash, recycled rubber powder, zinc oxide, calcium carbonate, and small lumps of coal.

Belt Conveyor

Belt conveyor plays a vital role in connecting various production equipment and ensuring the continuity and automation of the production process.

Chute Feeder

The chute feeder is widely used in industries such as mining, beneficiation, chemical processing, cement, and building materials. It plays a crucial role in the uniform and continuous feeding of materials from storage bins to crushing and transportation machinery.

GZT Vibrating Feeder

GZT Vibrating Feeder is specifically designed for light-duty conditions. stands out as an ideal feeding solution for mobile stations, semi-fixed stations, and small material yards.

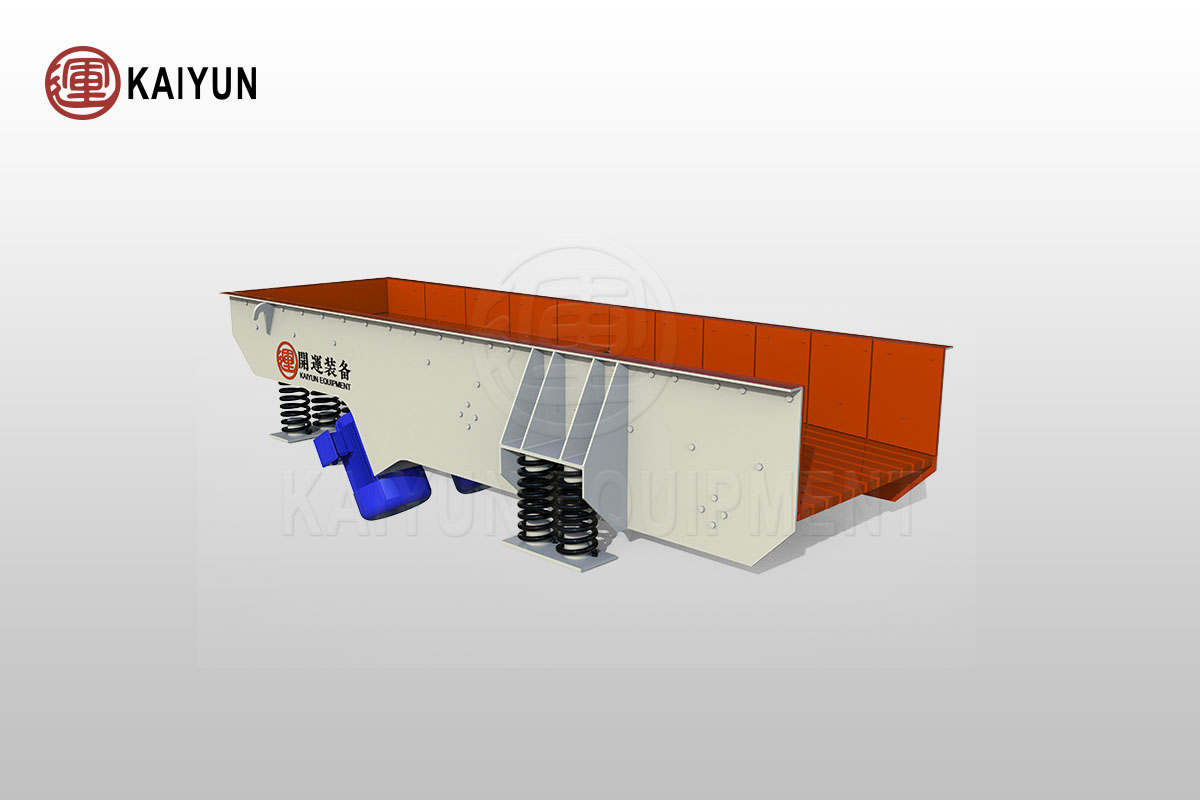

ZSW Vibrating Feeder

ZSW vibrating feeder is specifically engineered to meet the needs of industries such as metallurgy, coal mining, beneficiation, building materials, chemicals, and abrasives.

Pendulum Feeder

The Pendulum Feeder, designed for periodic reciprocating feeding of fine materials, is a crucial auxiliary device in the field of transportation machinery.