Product Introduction

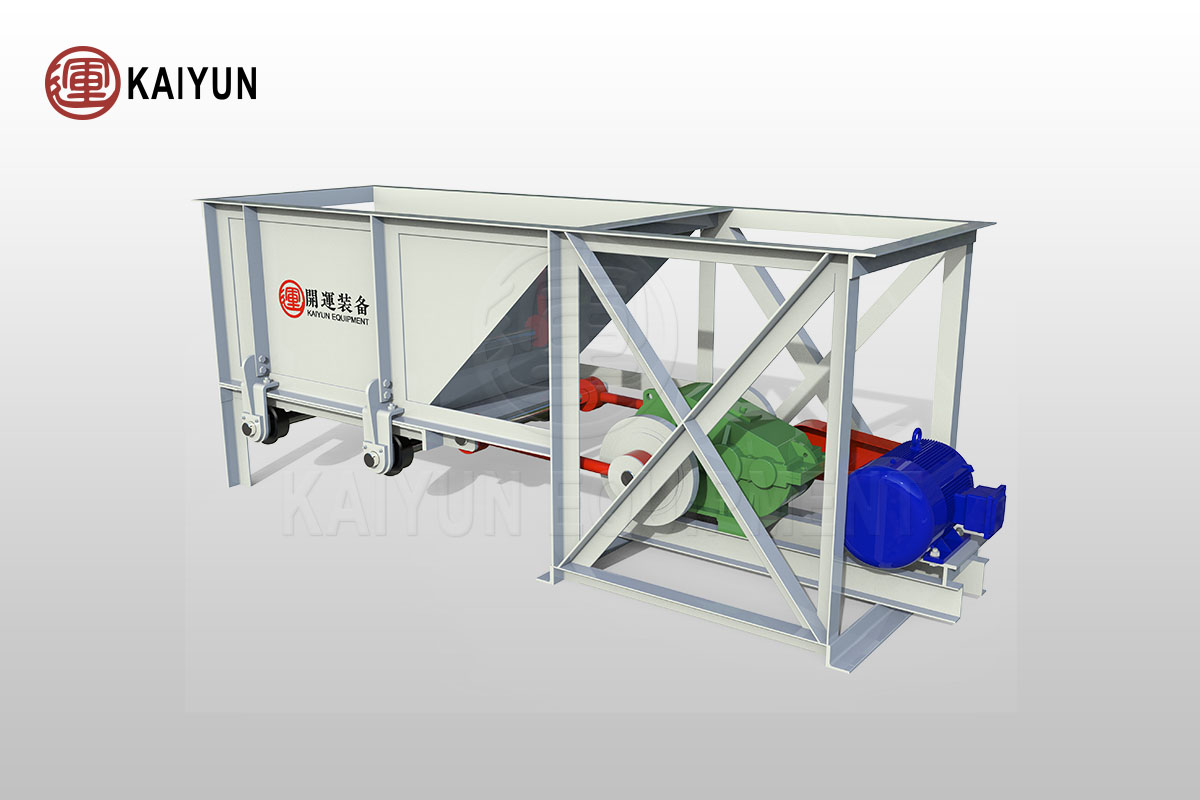

The chute feeder, designed specifically for large materials, is a periodic reciprocating feeding device widely used in industries such as mining, beneficiation, chemical processing, cement, and building materials. It plays a crucial role in the uniform and continuous feeding of materials from storage bins to crushing and transportation machinery.

The chute feeder unique structural design and flexible installation options ensure continuity and efficiency in the material handling process, making it an ideal choice for short-distance transport of block materials with a particle size of up to 160mm.

Table of Contents

Advantages and Features

Versatile Installation, Strong Adaptability

The chute feeder can be securely mounted on the ground or flexibly suspended above the material discharge port, meeting various installation requirements across different working conditions.

Flow Rate Adjustment, Easy Operation

Users can easily change and control the flow rate according to production needs, achieving uniform and continuous feeding. The simple operation and rapid response ensure precise and stable material supply.

Reciprocating Motion, Adjustable Stroke

The reciprocating motion of the chute bottom plate provides the driving force for material transport. The stroke size can be adjusted by the eccentric wheel of the drive device, with the eccentric distance being half of the stroke, accommodating various material handling requirements.

Sticky Ore Adaptability, Optimized Design

Based on practical experience in beneficiation plants, the eccentric distance for handling sticky ores should not be less than 30mm, ensuring efficient and stable operation when dealing with sticky materials.

Wide Chute Design, Size Matching

The chute width is approximately 2 to 2.5 times the maximum feeding particle size. This design ensures smooth passage of materials, preventing blockages and improving feeding efficiency.

Working Principle

The core working principle of the chute feeder is based on its unique mechanical linkage mechanism. The equipment is typically installed below the material discharge port of the storage silo, with materials falling onto the bottom plate of the chute. This bottom plate is positioned on rollers and connected to an eccentric mechanism and a double-output shaft gearbox. The gearbox is further connected to the motor via a coupling.

During operation, the motor drives the gearbox through the coupling, which in turn drives the eccentric plate to produce reciprocating linear motion between the bottom plate of the chute and the rollers. This reciprocating motion ensures the uniform feeding of materials. This process not only guarantees continuous material supply but also allows for precise control of the feed rate through fine adjustments of the stroke length.

Technical parameters

| Model | Discharge port size width*height (mm) | Upper limit feeding size (mm) | Feeding capacity (t/h) | Motor model | Motor power (kw) | Weight (kg) |

| CF300*300 | 300*300 | 50 | 10-20 | Y90L-4 | 1.5 | 265 |

| CF400*400 | 400*400 | 100 | 10-30 | Y112M-6 | 2.2 | 535 |

| CF600*500 | 600*500 | 200 | 10-50 | Y112M-4 | 4 | 1045 |

| CF700*500 | 700*500 | 250 | 10-60 | Y112M-4 | 4 | 1100 |

| CF980*1240 | 980*800 | 350 | 36-90 | Y160M-6 | 7.5 | 1710 |