Product Description

The Multi-functional color sorter is a high-end sorting equipment based on image recognition and intelligent algorithms. It is widely used in the identification and removal of defects such as color difference, foreign matter, mildew, etc. of various granular, flaky, irregular or mixed materials. Its modular design supports the combination of different imaging systems (visible light, near infrared, shape recognition, X-ray, etc.), realizing one machine for multiple uses and adapting to different industries and material requirements.

Multi-functional color sorter applicable material types

Minerals and building materials:

Quartz sand, feldspar, phosphate rock, lithium ore, calcium carbonate, etc.

Industrial sorting:

Salt particles, glass particles, metal particles, rubber impurities, etc.

Agricultural product processing:

Peanuts, corn, soybeans, sesame, coffee beans, rice, beans

Tea and Chinese medicinal materials:

Greentea, oolong tea, licorice, wolfberry, dried ginger slices, chrysanthemum, etc.

Plastic recycling industry:

PET bottle flakes, ABS, PE, PVC, plastic particles, flakes, etc.

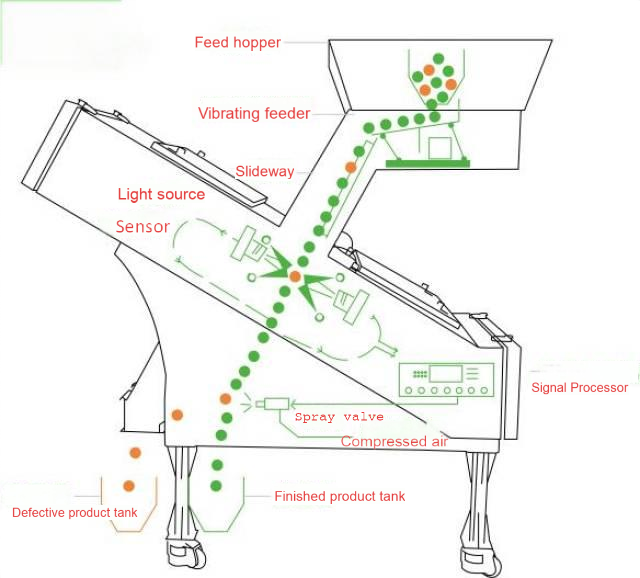

Working principle

When Multi-functional color sorter working, the material enters the color sorting area evenly through the vibration distribution system, and the high-definition camera (CCD/NIR/AI) takes high-speed photos of the material. The AI intelligent system analyzes the color, shape, impurities and other characteristics in real time, and removes impurities by controlling the high-frequency solenoid valve to jet, achieving accurate and efficient sorting.

Main advantages

One machine for multiple uses:

Multi-functional color sorter is suitable for a variety of materials.

Intelligent identification:

Multi-functional color sorter, supports color recognition, shape recognition, infrared recognition, mildew recognition, etc.

Easy switching:

Multifunctional color sorter, one-click switching of color sorting parameters, quick replacement of materials without tedious adjustments.

Self-learning function:

AI algorithm automatically optimizes recognition effect, saving manpower.

High-precision rejection:

Multi-functional color sorter, fastest response of 0.01 seconds, low false rejection rate.

Strong scalability:

Multi-functional color sorter, supports adding channels, lenses, sensors, etc., adapting to different scenarios.

Parameters

| Model | Execution unit | Production (kg/hour) | Color sorting accuracy | Carry-out ratio Good: Bad | Voltage | Power(kw) | Air consumption(L/min) | Dimensions(mm) | Weight (kg) |

| KD-32 | 32 | 300–400 | >99.9% | 13:1 | 220V/50Hz | 0.5 | 200–400 | 1100×450×1550 | 210 |

| KD-64 | 64 | 500–700 | >99.9% | 13:1 | 220V/50Hz | 0.8 | 200–400 | 1260×800×1550 | 350 |

| KD-128 | 128 | 800–1300 | >99.9% | 13:1 | 220V/50Hz | 1.4 | 600–1000 | 1314×1504×1760 | 600 |

| KD-192 | 192 | 1000–1800 | >99.9% | 13:1 | 220V/50Hz | 1.8 | 800–1400 | 1650×1504×1760 | 780 |

| KD-256 | 256 | 1600–2500 | >99.9% | 13:1 | 220V/50Hz | 2.2 | 1000–1800 | 1986×1504×1760 | 960 |

The specific output will vary with the different materials and impurity content. Depending on the raw materials and impurity content, it can range from one hundred kilograms per hour to more than ten tons.