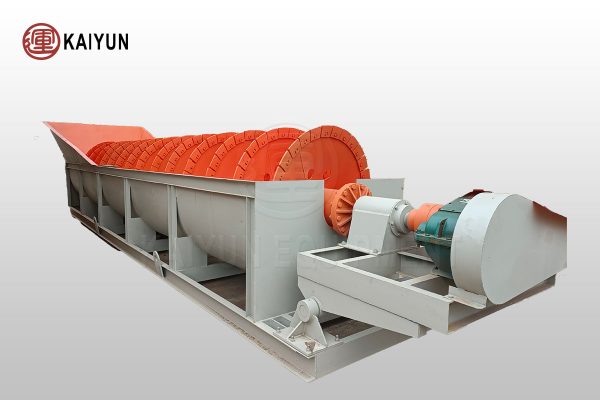

Product Introduction

The sinking spiral classifier is a well-designed and energy-efficient classification device, is specifically developed for processing ores with a particle size range of 0.15 to 0.07mm.

The sinking spiral classifier unique full-spiral blade sinking design ensures a large and deep settling area, achieving finer and more stable ore classification results.

Table of Contents

Advantages and Features

Deep Settling Zone Design

The sinking spiral classifier features a design where the spiral blades at the overflow end are fully submerged beneath the liquid level, creating a suitably deep and wide settling area.

This significantly enhances classification efficiency and accuracy.

Significant Energy Savings

Compared to traditional classifiers, the sinking spiral classifier saves 1-1.5 kwh of energy per ton of ore processed, demonstrating outstanding energy efficiency.

Reduced Maintenance Frequency

By eliminating the need for frequent maintenance associated with large scoop heads, the sinking spiral classifier lowers maintenance costs and improves equipment stability.

Balanced Impact Protection

The classifier effectively mitigates uneven impacts on the large and small gears, extending the equipment’s service life and reducing potential failure risks.

Working Principle

The sinking spiral classifier operates based on the differences in particle size and specific gravity of solid particles, utilizing their varying settling velocities in a liquid to achieve precise classification. During operation, finer ore particles float on the water surface and overflow with the water flow, while coarser particles settle to the bottom of the tank.

The spiral mechanism rotates slowly, stirring the finer particles and keeping them suspended at the water surface, where they flow towards the overflow weir and exit. Meanwhile, the coarser particles settled at the bottom are conveyed by the spiral to the discharge port as return sand.

At the overflow weir, the sinking spiral classifier is typically equipped with 4-5 spiral blades fully submerged in the slurry, creating a broad settling area and an appropriately deep classification pool. The slight agitation caused by the spiral has minimal impact on the surface of the slurry, ensuring a smooth classification interface, a large overflow volume, and fine particle size.

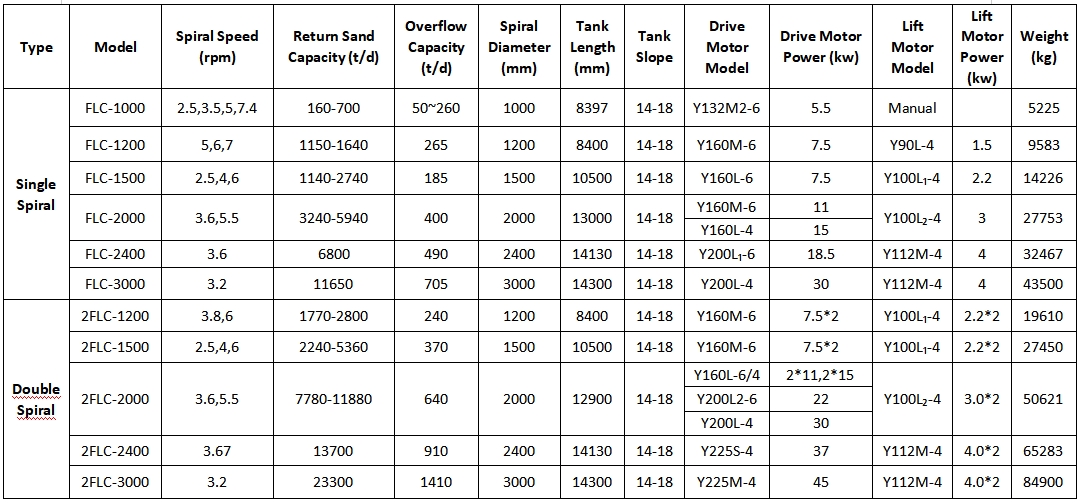

Technical Parameters