Product Introduction

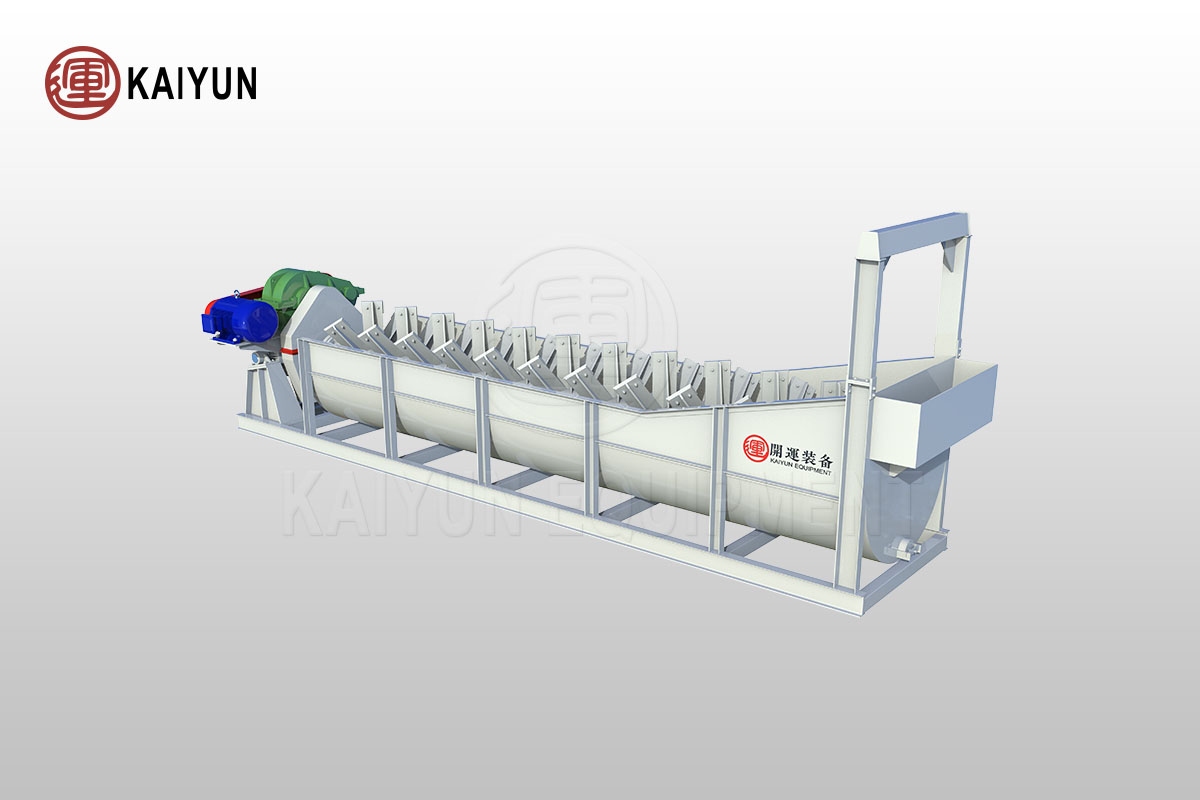

The High-Efficiency Stirring Scrubber is an advanced device designed specifically for dispersing ore slurry, removing and scrubbing surface impurities from minerals.

The High-Efficiency Stirring Scrubber is suitable for scrubbing and purifying particles of natural or artificial sand with particle sizes from 0-6mm, as well as for dispersing and separating various loose clayey ore particles or materials.

The scrubber effectively removes solvents and soil adhered to the surfaces of minerals or materials, providing clean raw material for subsequent processing or beneficiation stages.

Table of Contents

Advantages and Features

Compact Design and High Efficiency

The High-Efficiency Stirring Scrubber features a compact structure and occupies a small footprint, making it especially suitable for production environments with limited space. Additionally, the high-speed rotation of the main shaft drives a specially designed impeller that provides powerful scrubbing action, ensuring high-efficiency cleaning.

Durable Materials and Low Failure Rate

The scrubber is made from high-quality materials that resist material impact and abrasion, significantly extending the equipment’s service life. This reduces failure rates, lowers maintenance costs, and enhances the stability and reliability of the equipment.

Working Principle

The High-Efficiency Stirring Scrubber consists of key components including a motor, reducer, main shaft, upper, middle, and lower impellers, and a tank. During operation, the motor drives the main shaft to rotate via a hard-tooth surface reducer, which in turn drives the three specially designed rubber impellers at high speed. These impellers perform vigorous scrubbing on the materials entering the tank, effectively removing surface impurities and adhering substances.

The tank is designed as a hexagonal prism and is lined with wear-resistant rubber, which not only enhances the durability of the equipment but also ensures smooth material flow during the scrubbing process, thereby improving the cleaning effect. The entire scrubbing process, driven by the high-speed rotation of the impellers and the wear-resistant tank, achieves deep cleaning and dispersion of the materials, providing clean and evenly dispersed raw materials for subsequent processing or beneficiation operations.

Technical Parameters

| Model | Volume (m³) | Shape | ImpellerDiameter (mm) | ImpellerSpeed (r/min) | Motor Model | Motor Power (kw) | Motor Speed (r/min) | Weight (kg) |

| CXJ1.5 | 1.5 | hexagon | φ750 | 197 | Y200L-4 | 30 | 1480 | 1469 |

| CXJ2.8 | 2.8 | hexagon | φ1000 | 148 | Y250M-4 | 55 | 1480 | 4030 |

| CXJ4.4 | 4.4 | hexagon | φ1000 | 148 | Y280S-4 | 75 | 1480 | 6200 |