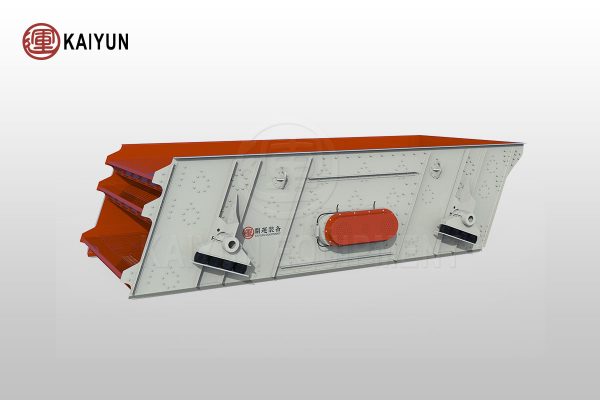

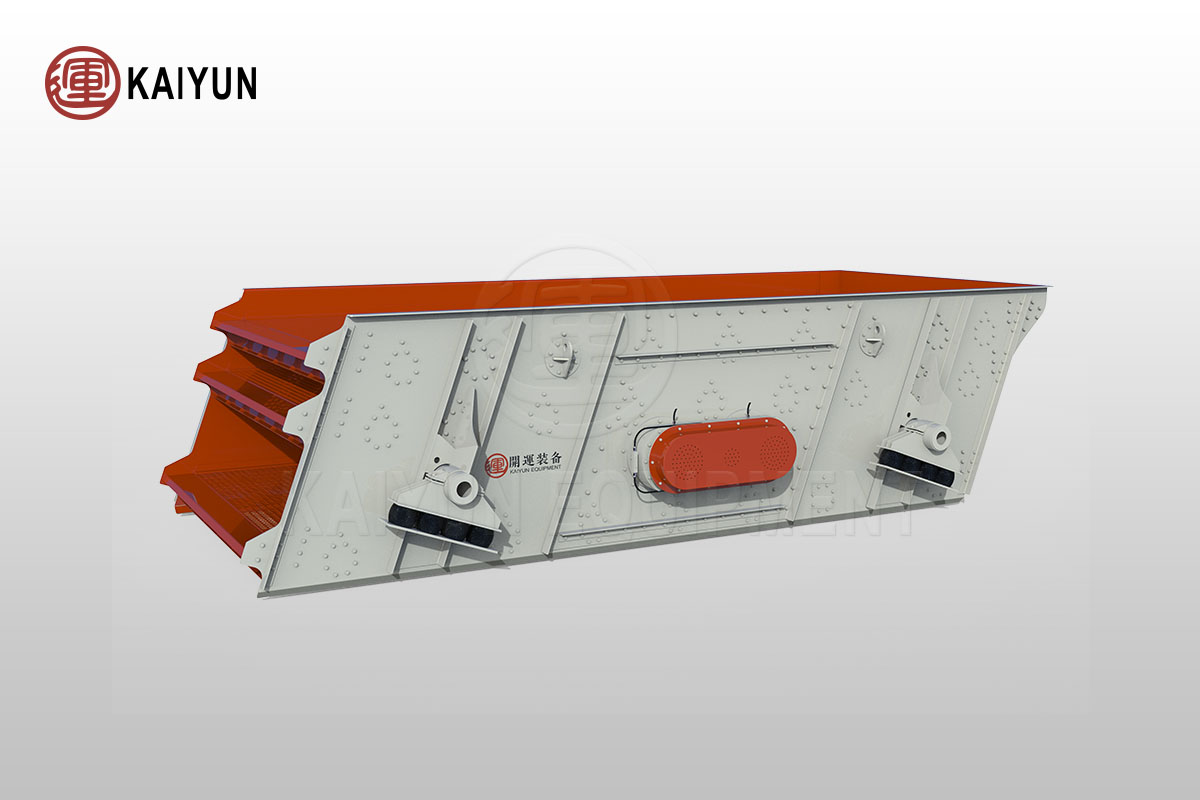

Product Introduction

YK series circular vibrating screen is called circular vibrating screen for short because its motion trajectory is close to a circle. It is mainly used for material size classification, and can also be used for dehydration, desludging, and de-mediuming.

YK series circular vibrating screen adopts a cylindrical eccentric shaft exciter and an eccentric block to adjust the amplitude. It runs smoothly, has multiple screening specifications, and high screening efficiency. In addition, wear-resistant rubber screens can be provided to make the materials stuck in the screen holes jump out and prevent the screen holes from being blocked.

Table of Contents

Advantages and features

⚙️ Multi-layer screening structure

Supports 2–4 screen layers for multi-grade particle size separation.

📐 Circular track for efficient screening

Equipped with an eccentric block vibrator for more uniform material flow and high screening efficiency.

🔧 Modular design for easy maintenance

YK series circular vibrating screen, easy screen replacement and simple, sturdy side panel structure.

🧱 Versatile material compatibility

YK series circular vibrating screen, suitable for sand, gravel, ore, coal, construction waste, and more.

🛠️ High overall strength and stable operation

YK series circular vibrating screen, high-strength welded frame for continuous, high-load screening.

🌍 Compatible with mobile crushing and screening systems

Easily combined with crawler or tire mobile stations to adapt to diverse working conditions.

Working principle

YK series circular vibrating screen is mainly composed of a screen box, a screen mesh, a vibrator and a vibration damping spring.

When working, the circular vibrating screen machine uses the motor through the V-belt to make the eccentric block of the vibrator produce a high speed. When the running eccentric block produces a large centrifugal force, it excites the vibrating screen box to produce a certain amplitude movement.

The material on the screen is subjected to the impact force transmitted by the screen box on the inclined screen surface, which produces a continuous throwing action. In the process of the material meeting the circular vibrating screen surface, the particles smaller than the screen hole are screened to achieve the screening operation.

Applications

Application Industries

Stone aggregate production lines (screening crushed stone, manufactured sand);

Pre-screening of metal ore beneficiation (iron ore, copper ore, etc.);

Coal, construction materials, and environmental solid waste treatment projects;

Urban construction waste recycling;

Typical Materials

Limestone, basalt, river pebbles, construction waste, iron ore, copper ore, coal, sand, etc.

Technical Parameters

| Model | Size W×L (mm) | NO.of decks | Inclination (°) | Oper.Speed (RPM) | Stroke (mm) | Power (kw) | Capacity (t/h) | Mesh Size (mm) |

| YK1230-2 | 1200×3000 | 2 | 18(18-25) | 800~900 | 7-12 | 11 | 25-200 | 2-70 |

| YK1545-2 | 1500×4500 | 2 | 18(18-25) | 800~900 | 7-12 | 11 | 45-380 | 2-70 |

| YK1545-3 | 1500×4500 | 3 | 18(18-25) | 800~900 | 7-12 | 15 | 45-380 | 2-70 |

| YK1845-2 | 1800×4500 | 2 | 18(18-25) | 800~900 | 7-12 | 15 | 60-450 | 2-70 |

| YK1845-3 | 1800×4500 | 3 | 18(18-25) | 800~900 | 7-12 | 22 | 60-450 | 2-70 |

| YK1860-2 | 1800×6000 | 2 | 18(18-25) | 800~900 | 7-10 | 15 | 75-600 | 2-70 |

| YK1860-3 | 1800×6000 | 3 | 18(18-25) | 800~900 | 7-12 | 30 | 75-600 | 2-70 |

| YK1860-4 | 1800×6000 | 4 | 18(18-25) | 800~900 | 7-12 | 37 | 75-600 | 2-70 |

| YK2160-2 | 2100×6000 | 2 | 18(18-25) | 800~900 | 7-12 | 22 | 85-700 | 2-70 |

| YK2160-3 | 2100×6000 | 3 | 18(18-25) | 800~900 | 7-12 | 30 | 85-700 | 2-70 |

| YK2160-4 | 2100×6000 | 4 | 18(18-25) | 800~900 | 7-11 | 37 | 85-700 | 2-70 |

| YK2460-2 | 2400×6000 | 2 | 18(18-25) | 800~900 | 7-12 | 22 | 100-800 | 2-70 |

| YK2460-3 | 2400×6000 | 3 | 18(18-25) | 800~900 | 7-11 | 30 | 100-800 | 2-70 |

| YK2460-4 | 2400×6000 | 4 | 18(18-25) | 800~900 | 7-10 | 37 | 100-800 | 2-70 |

| YK2760-2 | 2700×6000 | 2 | 18(18-25) | 800~900 | 7-12 | 30 | 120-900 | 2-70 |

| YK2760-3 | 2700×6000 | 3 | 18(18-25) | 800~900 | 7-11 | 37 | 120-900 | 2-70 |

| YK3072-2 | 3000×7200 | 2 | 20(20-25) | 800~900 | 7-11 | 37 | 150-1200 | 2-70 |

| YK3075-2T | 3000×7200 | 2 | 20(20-25) | 800~900 | 7-12 | 2×22 | 180-1800 | 2-150 |

| YK3075-3T | 3000×7200 | 3 | 20(20-25) | 800~900 | 7-12 | 2×30 | 180-1800 | 2-150 |

| YK3680-2T | 3600×7500 | 2 | 20(20-25) | 800 ~900 | 7-12 | 2×30 | 225-2250 | 2-150 |

| YK3680-3T | 3600×7500 | 3 | 20(20-25) | 800~900 | 7-12 | 2×37 | 225-2250 | 2-150 |

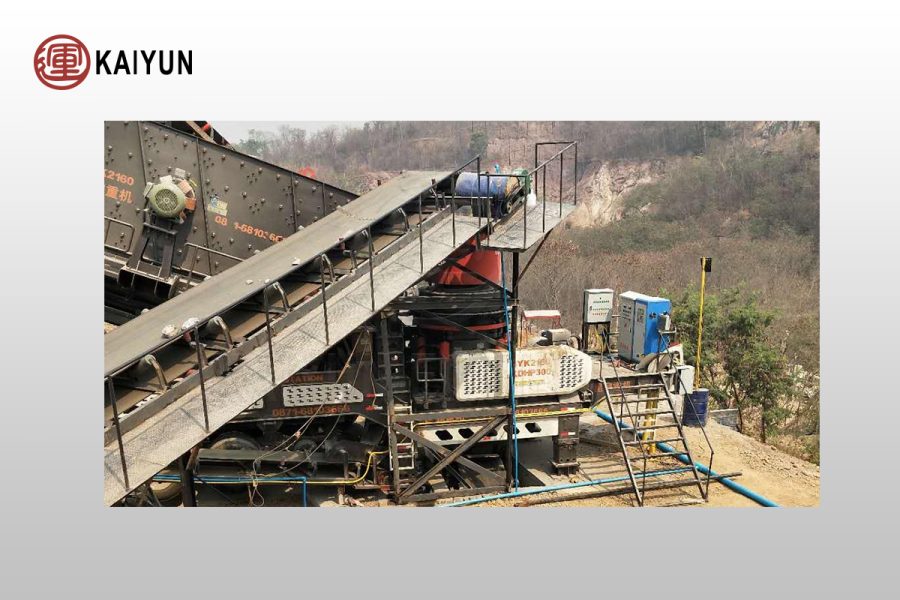

Customer Case

Sand and Gravel Aggregate Crushing and Screening Project in Thailand

Model: YK2160-3

Raw Material: Granite

Capacity: 300 tons/hour

Particle Size Classification: 10–20 mm

Customer Feedback: Stable operation, accurate screening, and easy maintenance.