mining equipment

KAIYUN EPC MINE SERVICE

Integrated management of the entire process and controllable risks ensure that project budget investment and planned construction period are met and production is achieved, thus maximizing customer benefits.

Products

Expert in Intelligent Mining Equipment Manufacturing

HPT Series Multi-Cylinder Hydraulic Cone Crusher

High-performance hpt series multi-cylinder hydraulic cone crusher for granite, basalt, iron ore, and hard rock. Ideal for mining, aggregates, and construction applications.

KNP Series Impact Crusher

KNP Series Impact Crusher for sand and stone production. High crushing ratio, cubic output shape, and ideal for limestone, concrete, and construction waste.

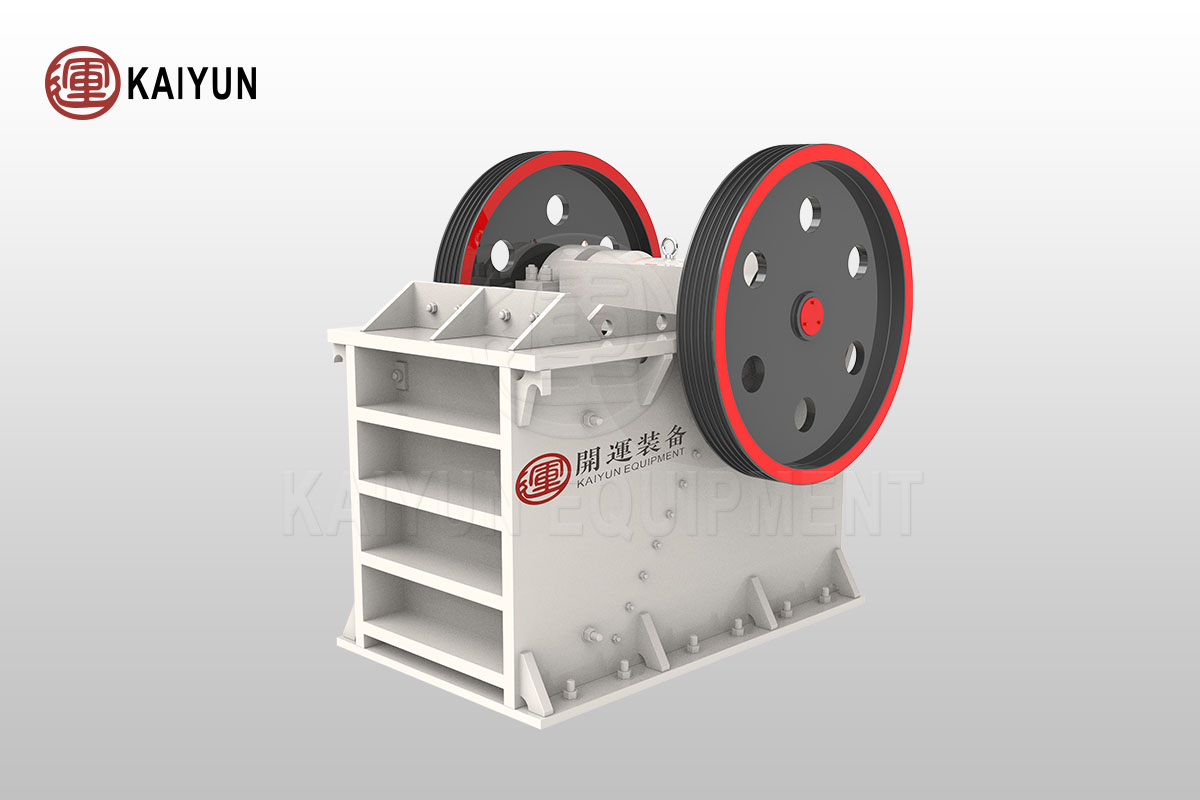

PE Series Jaw Crusher

Durable PE Series Jaw Crusher for primary crushing of hard rock, ore, and aggregates. High crushing ratio, easy maintenance, and wide material adaptability.

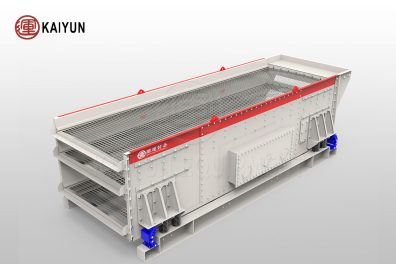

Three-axis Horizontal Vibrating Screen

High-performance horizontal vibrating screen with triple-shaft drive. Ideal for fine, sticky, and wet material screening in mining, sand, and aggregates.

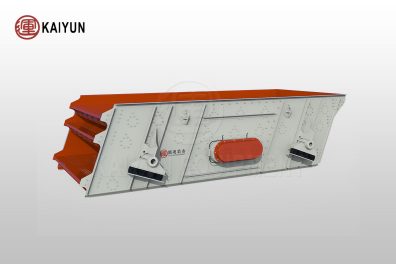

YK Series Circular Vibrating Screen

YK circular vibrating screen for sand, gravel, and ore screening. Durable, high-capacity, and ideal for mining, aggregates, and construction industries.

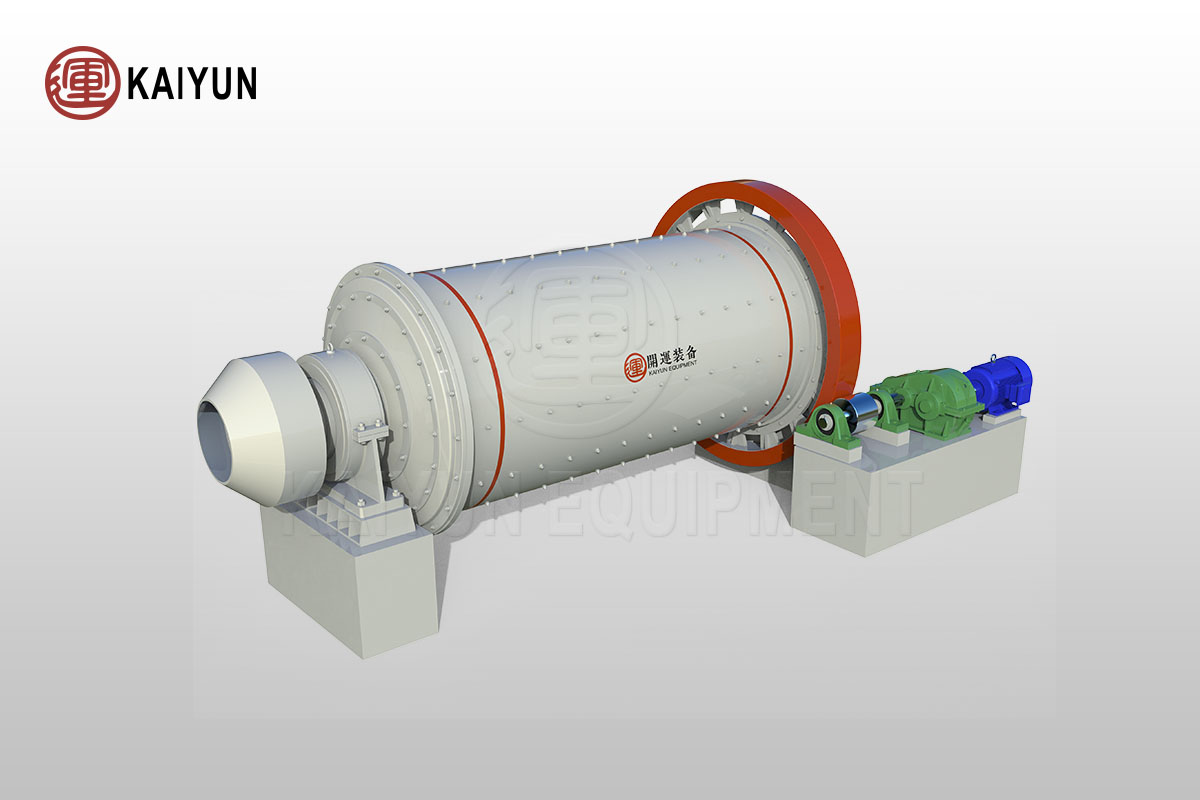

MQGJ Wet Energy-Saving Grate Ball Mill

The Kaiyun MQGJ Wet Energy-Saving Grate Ball Mill has become an indispensable high-performance equipment in the field of mineral processing, thanks to its advanced design concepts, innovative technological applications, and robust structural materials.

PAIN POINTS IN MINEDEVELOPMENT PROJECTS

Almost all exceeds the investment budget

Almost all failed to meet the production target on schedule

Almost all need technological transformation since put into production

SERVICES

Our Core

Services

KAIYUN offers innovative

mobile crushing and screening solutions,

tailored for aggregate, mining, and more.

Equipment R&D

The company independently develops a full range of mobile crushing and screening equipment across eight major product series.

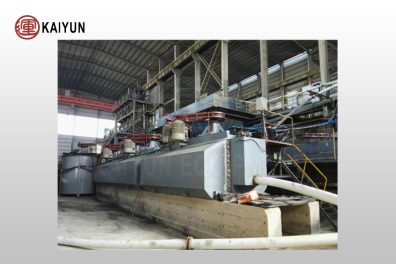

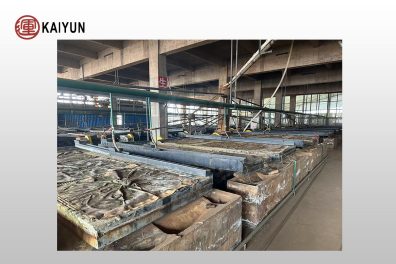

Manufacturing

Multiple production bases support large-scale manufacturing, providing high-quality equipment.

Flexible Configuration

Customizable primary, secondary, and tertiary crushing station equipment to meet specific customer needs.

Process Optimization

Optimization of crushing and screening processes to enhance efficiency and meet customer demands.

Process

Intelligent mining beneficiation production process

Cu-Pb-Zn Ore Beneficiation Process

Cu-Pb-Zn Ore Beneficiation Process adopts a mixed flotation-concentrate regrinding process, which aims to reduce the grinding cost, is easy to manage, and uses new non-toxic flotation reagents to achieve an efficient and environmentally friendly beneficiation process.

Ilmenite Beneficiation Process

Ilmenite beneficiation process is mainly includes crushing, grinding, gravity separation, magnetic separation, flotation and combined beneficiation.

Tin Ore Beneficiation Process

Tin ore is usually separated by gravity separation because its density is greater than that of the associated minerals. However, since the ore may contain various iron oxide minerals (such as magnetite, hematite, etc.), these minerals are difficult to be effectively separated from the tin ore by gravity separation or flotation, so magnetic separation or flotation methods are also needed.

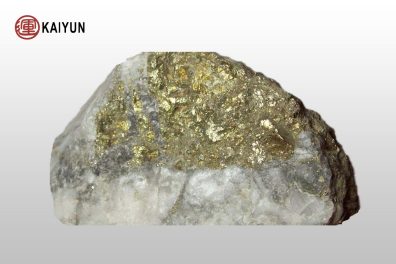

Placer Gold Beneficiation Process

Placer gold is generally found in rivers, lakes, valley alluvial layers, etc. The beneficiation process mainly relies on gravity separation, which is widely used in the African market because of its simple operation, low investment, environmental protection and pollution-free.

Gold CIL Process

CIL (Carbon-in-Leach) is a highly efficient gold extraction process used in modern gold processing plants. Compared to traditional methods, the CIL process integrates leaching and adsorption into a single step, improving gold recovery, reducing processing time, and lowering operational costs. Our modular and customizable Gold CIL Plants are widely used in Africa, Asia, and South America for both oxide and sulfide gold ores.

Gold CIP Process

Gold CIP (Carbon-in-Pulp) is a widely used method for gold extraction from low-grade ore, especially in medium to large-scale mining operations. Our turnkey Gold CIP plants offer complete, efficient, and environmentally friendly solutions for maximizing gold recovery.

Your are

just 10 minutes away from the

support you need.

complete the form and get immediate assistance!

News

Enhancing Efficiency Through Advanced Mining Equipment

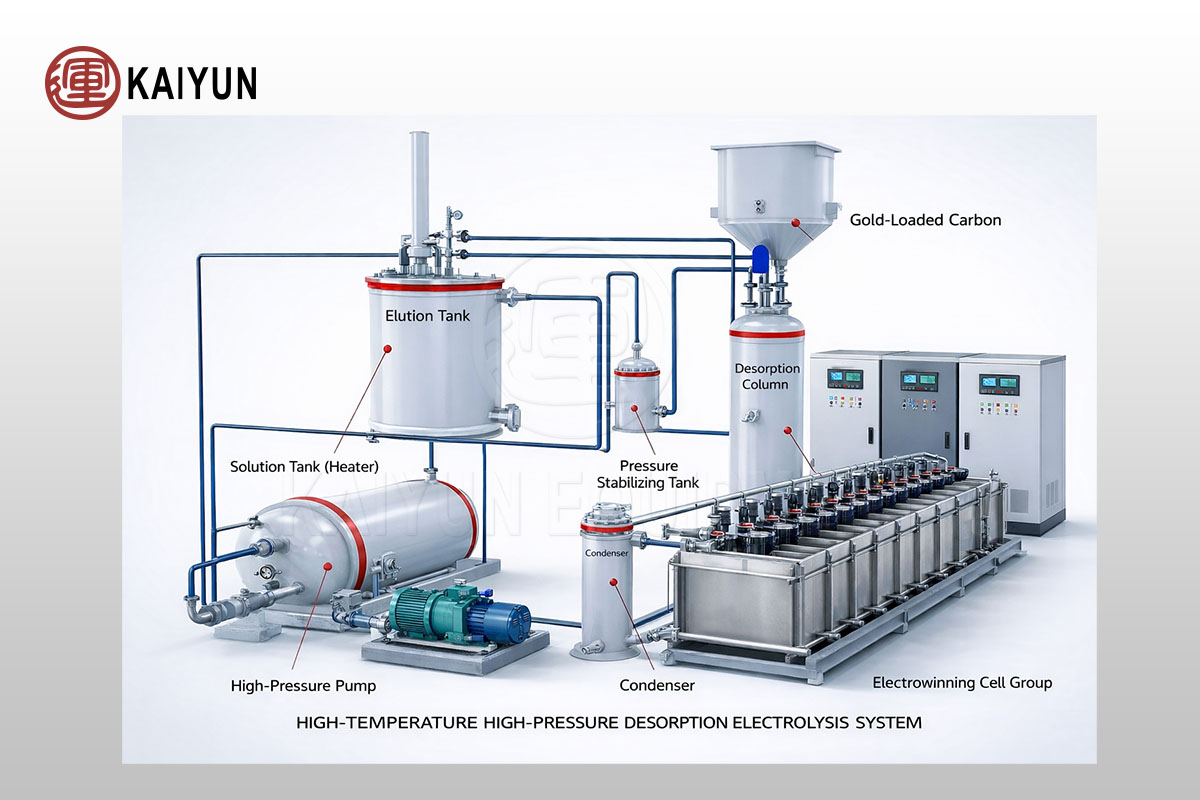

High Temperature High Pressure Desorption Electrolysis System for Gold CIP/CIL Plant

High temperature high pressure desorption electrolysis system for gold CIP/CIL processing plant. Efficient gold desorption and electrowinning solution with high recovery rate, stable operation and automated control.

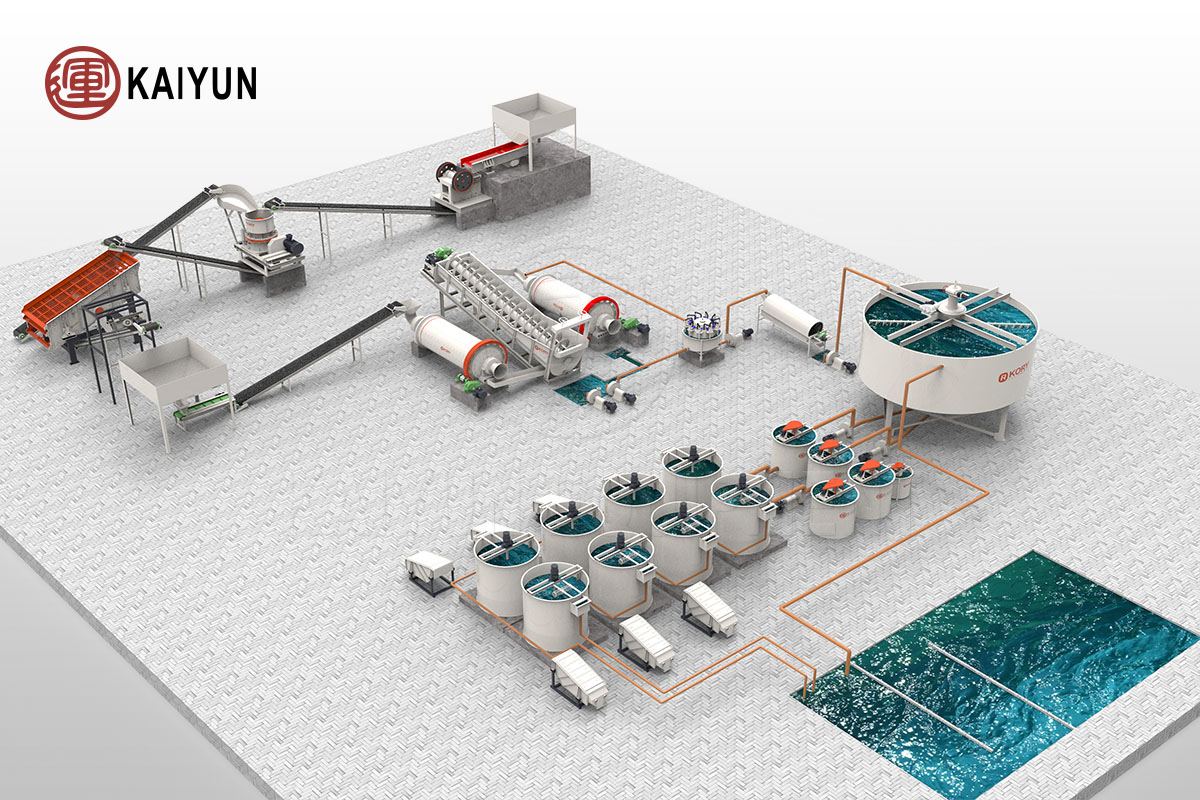

Gold Ore CIP Processing Line: Core Equipment Overview

Complete Gold Ore CIP (Carbon-in-Pulp) Processing Line covering crushing, grinding, leaching, carbon adsorption, desorption-electrolysis, and water recycling. High gold recovery rate, stable operation, lower costs, and eco-friendly design. Ideal solution for modern gold mining projects.

Core Requirements for Activated Carbon in Gold CIP Processing

Learn the core requirements for activated carbon in Gold CIP processing. Improve CIP adsorption efficiency, gold recovery, and plant stability with the right carbon selection.

COMPANY

Why People Choose us?

Innovative equipment, tailored solutions, and exceptional manufacturing quality ensure optimal performance for diverse applications.

Customer-Centric Design

We focus on meeting unique client needs with precision-engineered solutions.

Cutting-Edge Technology

Advanced R&D drives innovation in every product we create.