Introduction

Barete is brittle and fragile, and the crystals are large tubular. The general beneficiation methods for barite selection are gravity separation, magnetic separation, and flotation.

Application Field

Processing of high-whiteness fine powder and ultrafine powder High-whiteness finely crushed barite powder is obtained by crushing, washing, and whitening the barite ore. Produce barium salt products such as Lithopone (zinc barium white), barium chloride, barium hydroxide, etc.

Table of Contents

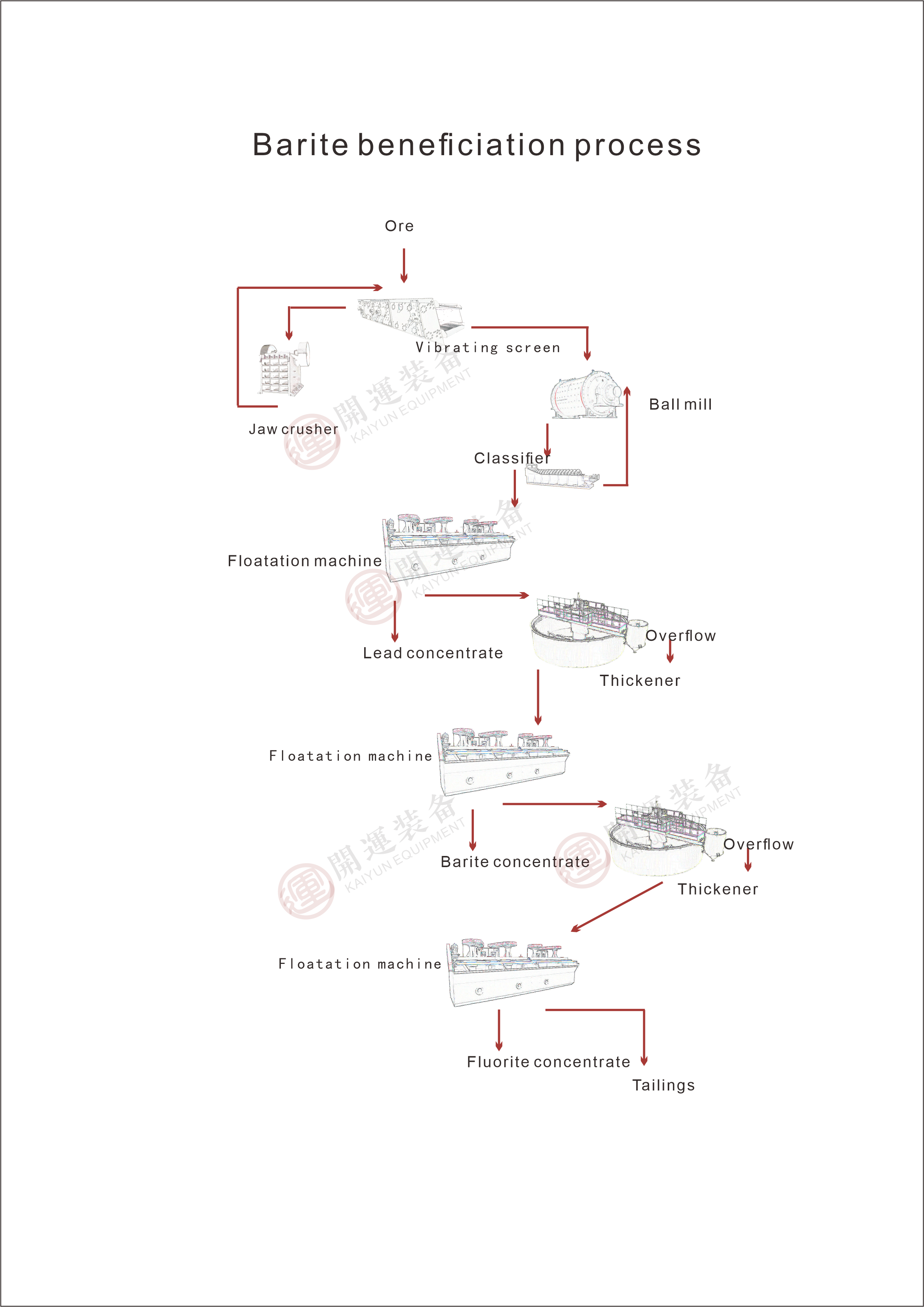

Process Flow

Crushing and screening

The crushing process uses a jaw crusher and a two-stage crushing process to crush the large pieces of barite mined.

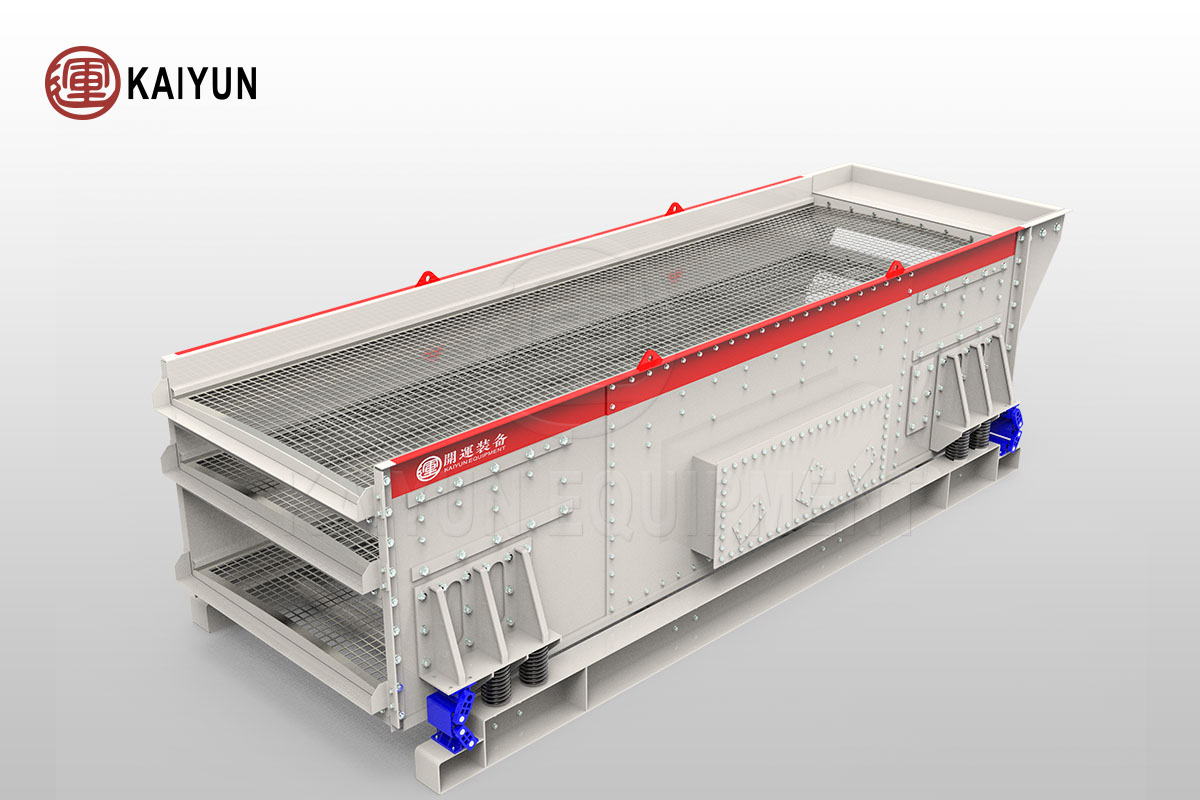

The screening process uses a circular vibrating screen with large processing capacity, high screening efficiency, and simple and practical. This type of vibrating screen has a low failure rate, large processing capacity, high screening efficiency, and is easy to operate. It is an ideal equipment for barite ore screening.

The jigging sorting process uses two types of jigging machines to jig and sort the coarse and fine particle barite materials after crushing.

Gravity separation

The usual practice for barite gravity separation is crushing and screening, and then the jigging process is used to obtain a high-grade concentrate, with a product grade of more than 80%. Jigging machines are used as the main equipment for sorting and purification of barite ores. It has the characteristics of energy saving, high efficiency, environmental protection, etc., and has high economic benefits.

Magnetic separation

Wet magnetic separators are usually used to select some iron-containing minerals such as siderite, which are used as barite raw materials for barium-based medicines that require very low iron content.

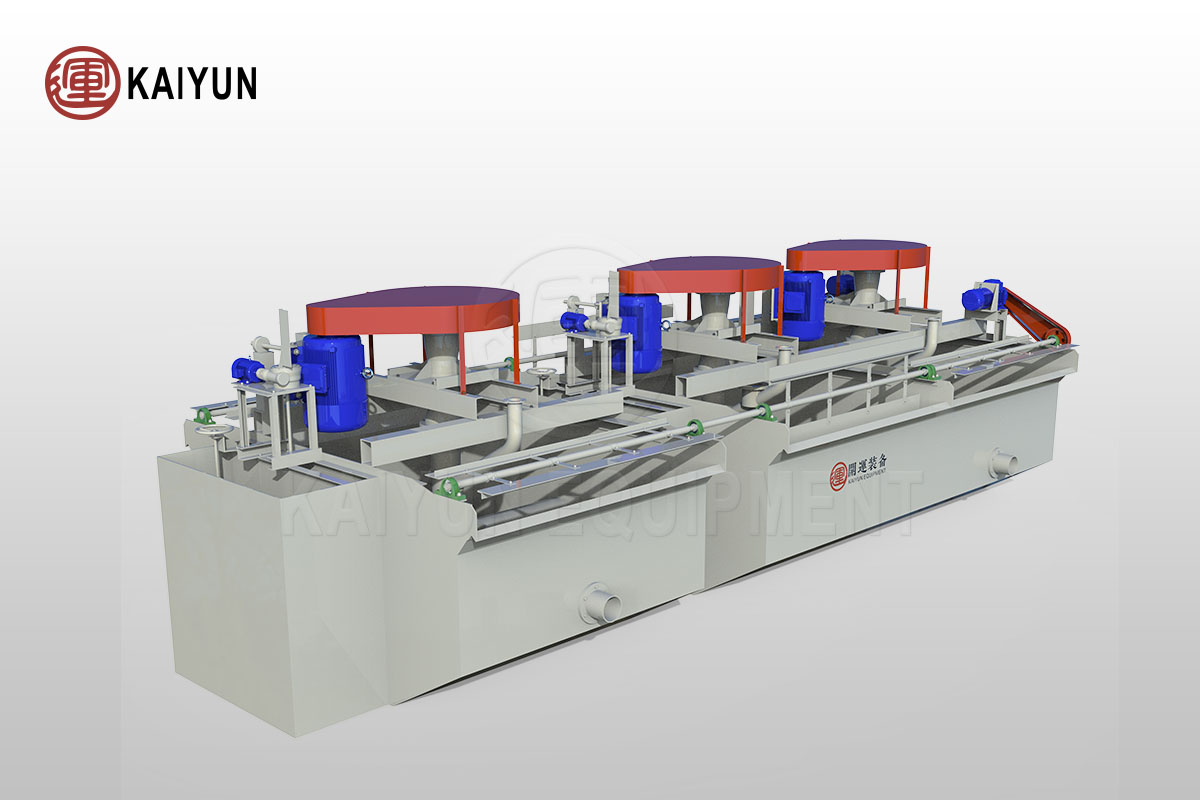

Floatation

Floatation is often used to separate barite ores with very fine embedded particle sizes and their gravity separation tailings. Depending on the adsorption method, anionic collectors such as fatty acid alkyl sulfates and alkyl sulfonates or cationic amine collectors are used to float barite ores.

Process Flow Chart