Product Introduction

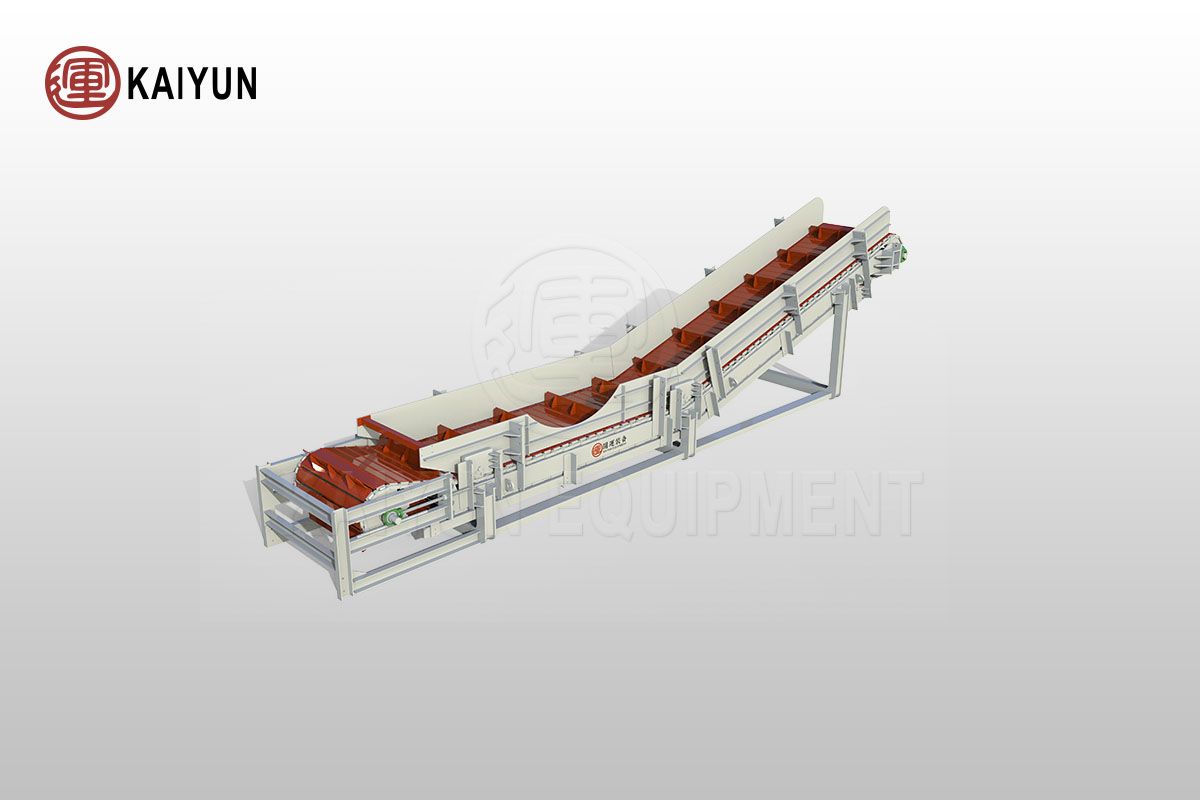

The plate feeder, specializing in short-distance material transport, is categorized into heavy-duty, medium-duty, and light-duty types based on varying loads and operating conditions. It is widely used in large-scale mineral processing plants for primary crushing and screening workshops, as well as in the cement and building materials industries.

The plate feeder plays a crucial role in the continuous and uniform supply of materials from storage bins to primary crushers. It is also suitable for short-distance transport of materials with larger particle sizes and higher specific gravities, ensuring the continuity and stability of production processes.

Table of Contents

Advantages and Features

Flexible Installation, Adaptable to Various Conditions

Whether installed horizontally or inclined (with an angle ≤ 12°), the plate feeder can adapt to different site layouts, providing customized solutions for material transport.

Protective Design, Ensuring Safety

To prevent direct impact of materials on the feeder, the design of the storage bin should avoid empty conditions, ensuring stable operation of the equipment and continuous material supply.

Large Particle Compatibility, Wide Applicability

Capable of handling feed sizes up to 1000mm, the plate feeder meets diverse material processing needs, accommodating both large ore chunks and fine particles with ease.

Working Principle

The core working principle of the plate feeder lies in its sophisticated mechanical linkage design. Power from the motor is transmitted through a reducer, driving the reciprocating movement of the connecting rod in the eccentric mechanism. Simultaneously, a pawl drives the ratchet, which rotates the driving sprocket, consequently moving the chain plate intermittently to achieve precise material transport.

This process not only ensures continuous feeding of materials but also effectively controls the transport rhythm, enhancing production efficiency.

Technical parameters

| Model | Chain plate width(mm) | Center distance of sprocket (mm) | Chain plate speed (m/s) | Feed size (mm) | Capacity (m³/h) | Motor model | Power (kw) | Dimensions (L*W*H) (mm) | Weight (kg) |

| QPF50-6 | 500 | 6000 | 0.16 | 160 | 60 | Y160M-6 | 7.5 | 7476x2745x980 | 3894 |

| QPF50-9.5 | 500 | 9500 | 0.16 | 160 | 60 | Y160M-6 | 7.5 | 10976x2720x980 | 5048 |

| QPF50-12 | 500 | 12000 | 0.1 | 160 | 41 | Y160M-6 | 7.5 | 14276x2790x980 | 6103 |

| QPF50-14 | 500 | 14000 | 0.16 | 160 | 60 | Y160L-6 | 11 | 15476x2826x980 | 7315 |

| QPF80-6 | 800 | 6000 | 0.16 | 160 | 107 | Y160M-6 | 7.5 | 7476x3045x980 | 4274 |

| QPF80-10 | 800 | 10000 | 0.16 | 160 | 107 | Y160M-6 | 7.5 | 11476x3045x980 | 5832 |

| QPF80-12 | 800 | 12000 | 0.16 | 160 | 107 | Y160L-11 | 11 | 13476x3126x980 | 6556 |